Hydrolevel 400 Series User Manual

Page 2

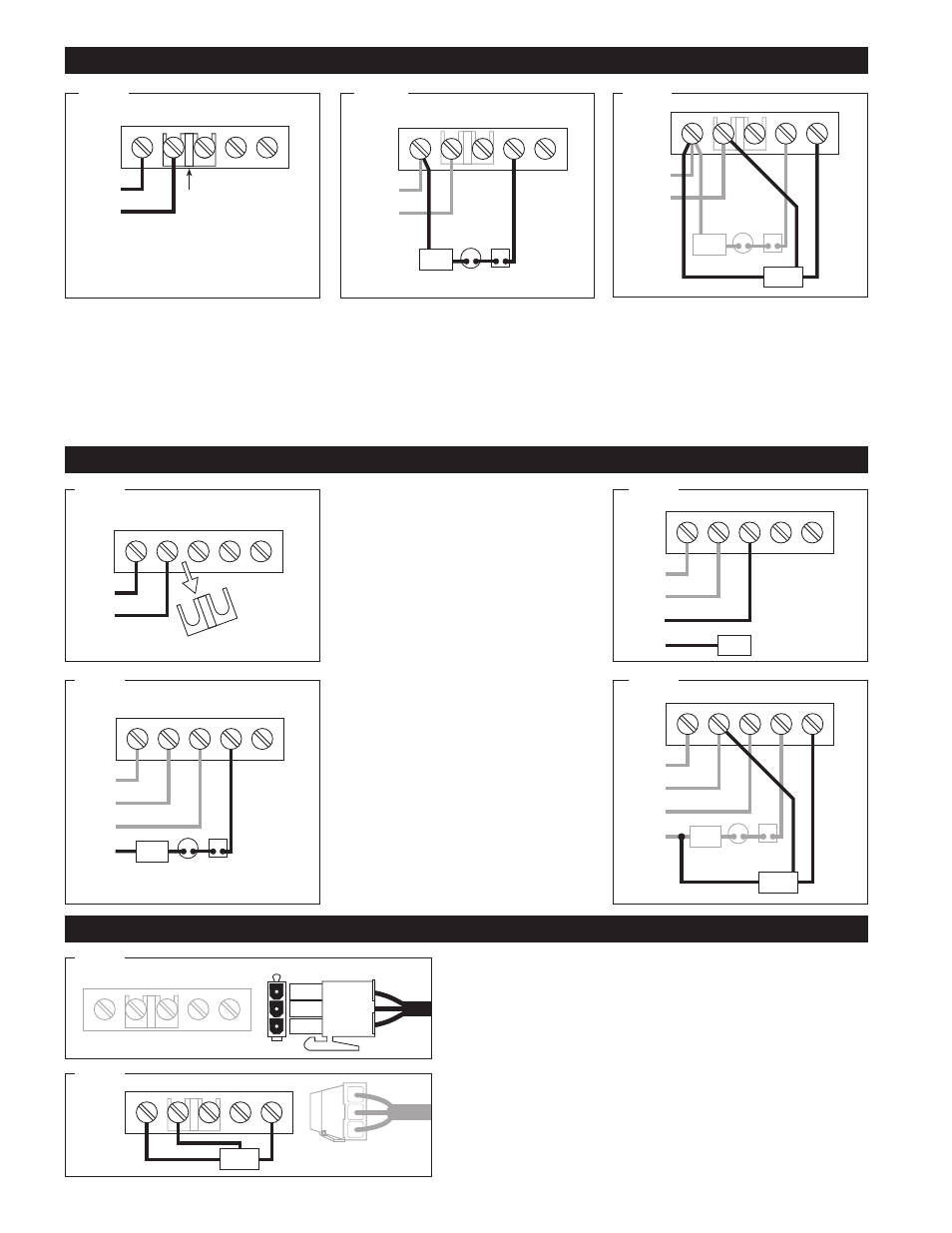

A1

Connect input voltage (24 VAC, 60 HZ) to

terminals 1 and 2. 24 VAC, 60 HZ must be supplied

to terminals 1 and 2 for internal operation of the

control.

A3

Optional water feeder connection. Connect

feeder N to terminal 2. Connect Feeder H to termi-

nal 1. Connect feeder “FEED” or “W” to terminal A.

For water feeders with 2 leads, connect feeder

common to terminal 2 and feeder hot to terminal A.

Note: Use of a solenoid valve or McDonnell &

Miller Model 101A water feeder may cause flood-

ing and is not recommended for use with this low

water cut-off.

24VAC

HOT

COMMON

+

0

LIMIT

CONTROLS

A

P2

P1

1

2

BURNER

CIRCUIT

WATER

FEEDER

BURNER

POWER

SOURCE

24VAC

HOT

COMMON

BURNER

CIRCUIT

A

P2

P1

1

2

BURNER

POWER

SOURCE

BURNER

POWER

SOURCE

24VAC

+

0

LIMIT

CONTROLS

A

P2

P1

1

2

HOT

COMMON

BURNER

CIRCUIT

BURNER

POWER

SOURCE

24VAC

A

P2

P1

1

2

FACTORY

INSTALLED

JUMPER

COMMON

HOT

BURNER

POWER

SOURCE

24VAC

+

0

LIMIT

CONTROLS

A

P2

P1

1

2

BURNER

CIRCUIT

WATER

FEEDER

24VAC

A

P2

P1

1

2

REMOVE

JUMPER

24VAC

+

0

LIMIT

CONTROLS

A

P2

P1

1

2

BURNER

CIRCUIT

HOT

COMMON

BURNER

POWER

SOURCE

P2

2

1

A

P2

P1

1

2

A

P2

P1

1

2

WATER

FEEDER

WIRING METHOD A: SAME POWER SOURCE FOR CONTROL AND BURNER CIRCUIT.

ᮤ

B1

Remove jumper between terminals 1

and P1. Connect input voltage (24 VAC, 60 HZ) to

terminals 1 and 2. 24 VAC 60 HZ must be supplied

to terminals 1 and 2 for internal operation of the

control.

Connect hot lead from the burner

B2

ᮣ

ᮣ

control circuit to terminal P1. This terminal sup-

plies power to terminal P2 in normal operating

conditions when water is at the probe. Connect

common to burner circuit. Note: Consult boiler

manufacturer instructions for proper terminal con-

nections.

ᮤ

B3

Connect terminal P2 to burner circuit in

series with and before other limit controls.

Optional water feeder connection.

B4

ᮣ

ᮣ

Connect feeder H to terminal 1. Connect feeder

“FEED” or “W” to terminal A. Connect terminal N to

common of the burner circuit supply. For feeders

with two leads, connect feeder hot to terminal A

and connect feeder common to common of the

burner circuit supply. Note: Use of solenoid valve

or McDonnell & Miller model 101A water feeder

may cause flooding and is not recommended for

use with this low water cut-off.

A2

Connect terminal 2 to burner circuit com-

mon. Connect terminal P2 to burner Circuit in

series with other limit controls. Consult boiler

manufacturer instructions for proper terminal con-

nections. Control should be wired in series with

and before other limit controls.

A1

A2

A3

B1

B3

C1

C2

B2

B4

WIRING METHOD B: SEPARATE POWER SOURCE FOR CONTROL AND BURNER CIRCUIT.

WIRING METHOD C: PLUG CONNECTOR.

ᮤ

C1

Plug wire harness connector into matching end on circuit board. IMPOR-

TANT: Factory installed jumper must be in place between

terminals 1 and P1.

ᮤ

C2

Optional water feeder connection. Connect feeder N to terminal 2.

Connect Feeder H to terminal 1. Connect feeder “FEED” or “W” to terminal A.

For water feeders with 2 leads, connect feeder common to terminal 2 and feeder hot

to terminal A. Note: Use of a solenoid valve or McDonnell & Miller Model 101A

water feeder may cause flooding and is not recommended for use with this low

water cut-off.