Multi-deck rotary switches, Series 42, Adjustable stop switches: series 42 and 44 – Grayhill Multi-Deck Rotary Switches 54 Series User Manual

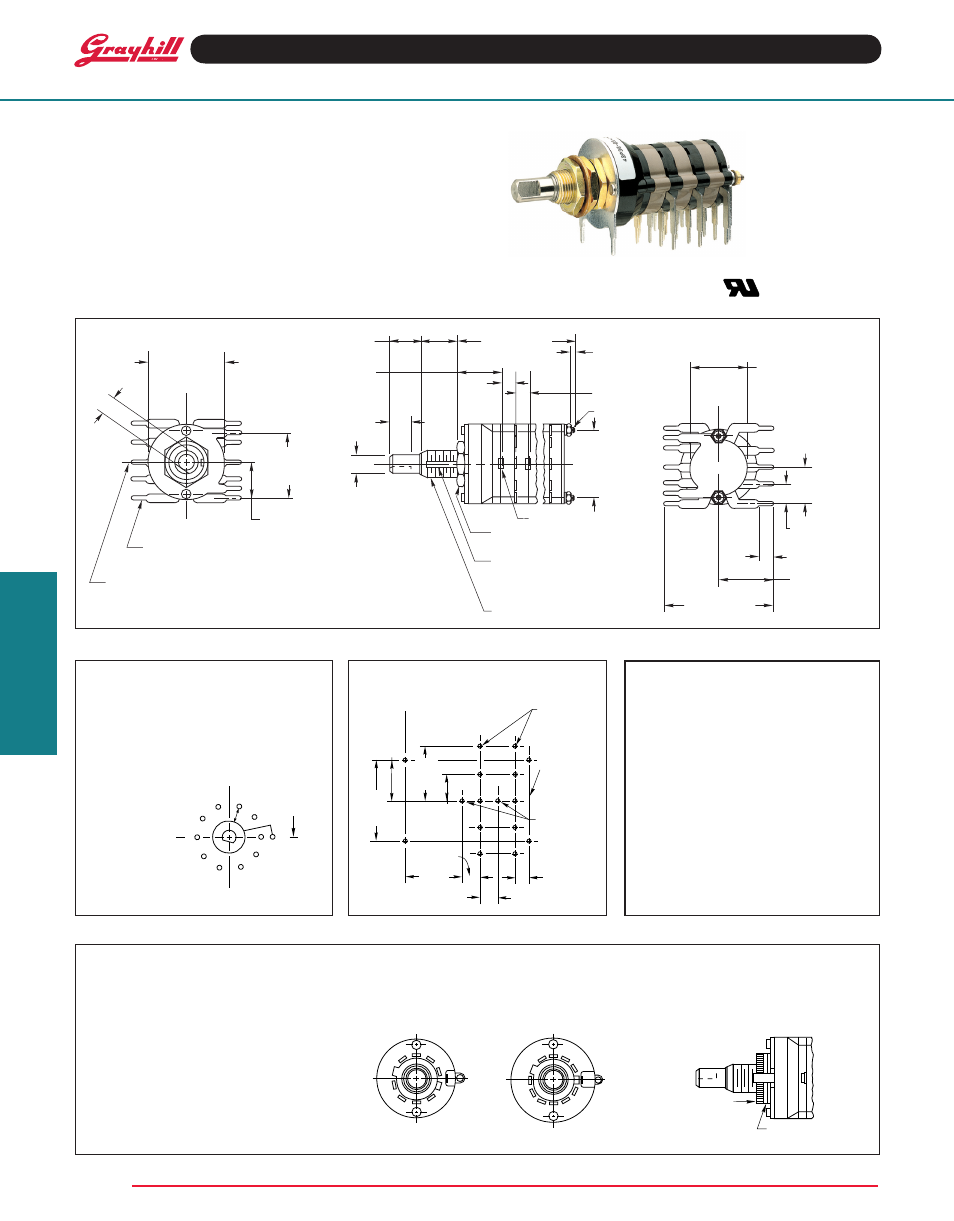

Page 3: Dimensions, 1" diameter, 1 amp, pc mount, Pc board mounting pattern, Circuit diagram: pc mount, Standard style, Shaft and panel seal: srs. 42 & 44 standard style

Grayhill, Inc. • 561 Hillgrove Avenue • LaGrange, Illinois 60525-5997 • USA • Phone: 708-354-1040 • Fax: 708-354-2820 • www.grayhill.com

Rotary Switches

Multi-Deck Rotary Switches

The standard and UL recognized switches are also

available with adjustable stops. Two removable

stop washers allow you to limit the number of

switch positions as needed. A knurled nut is

supplied to secure the washers if desired.

These switches have no bushing keyway. All other

dimensions, ratings and characteristics are the

same as the standard fixed stop styles. Although

not military qualified, the adjustable styles are

useful in military equipment prototypes. However,

when submitting the equipment for government

approval, the fixed stop qualified style should

be substituted.

Equivalent Styles

For style 42A36, use 42D36,

For style 44A30, use 44D30

For style 42M36, use 42D36 initially

ADJuStABLE StOP SWItCHES: Series 42 and 44

Front Views

Series 42

Series 44

Switch is Viewed From Shaft End

and Shown in Position No. 1

Note: All common terminals are located above

base terminals as shown.

PC BOARD MOuNtING PAttERN

termination

One-sided termination is standard for switches with 2 to 5

positions per pole. Two-sided termination is standard for

switches with 6 thru 10 positions per pole.

6 thru 10 positions

per pole and ter-

minals from one

side of switch are

available on special

order. See Special

Options, page F-10

or contact Grayhill.

Shown for a two deck switch

CIRCuIt DIAGRAM: PC Mount

ONE POLE

Standard Style

DIMENSIONS

in inches (and millimeters)

Grayhill part number and date code marked on detent cover label. Customer part num-

ber marked on request. UL recognized marking as required.

C

L OF

BUSHING

KEyWAy

7

6

5

4

3

2

1

8

9

10

C1

1.000 ± .010

(25,4 ± 0,25)

DIA.

TERMINAL DIMENSIONS AT THIS

POINT ARE .050 ± .005 (1,27 ± 0,13)

WIDE BY .020 ± .003 (0,51 ± 0,08) THICK

.375 ± .015

(9,53 ± 0,38) TYP.

.750 ± .010

(19,05 ± 0,25)

TYP.

OF BUSHING

KEYWAY

C

L

.250 + .001 –.002

(6,35 + 0,03 –0,05)

DIA.

3/8-32 UNEF-2A THREAD

(MTG. HOLE=3/8 DIA. MIN.)

BUSHING KEYWAY

.066 ± .002 (1,68 ± 0,05) WIDE BY

.036 ± .003 (0,91 ± 0,08) DEEP

FROM A .375 (9,53) DIA.

INTEGRAL ASSEMBLY NUT,

DO NOT REMOVE

COMMON LUG

.250 ± .020

(6,35 ± 0,51)

.830

± .010

(21,08

± 0,25)

DIM. A + .046 – .020

(+1,17 –0,00)

.437 ± .020

(11,10 ± 0,51)

.600 ± .031

(15,24 ± 0,79)

DIM. B REF.

STUD

PROJECTION

#1 THREAD

.174

± .010

(4,42

± 0,25)

C

L C

L C

L

.174 ± .010

(4,42 ± 0,25)

.786 ± .010

(19,96 ± 0,25)

DIA.

.500 ± .015

(12,7 ± 0,38)

TYP.

1.470 ± .020

(37,34 ± 0,51)

TYP.

.735 ± .010

(18,67 ± 0,25) TYP.

.187 ± .015

(4,75 ± 0,38) TYP.

.250 ± .015

(6,35 ± 0,38) TYP.

1

10

6

5

4

3

2

9

8

7

GRAYHILL

.219

± .005

(5,56

± 0,13)

8

9

6

5

4

3

FIRST

STO

P

7

8

9 10

11

6

5

4

3

2

FIR

S

T

S

TO

P

ADJUSTABLE STOP

WASHERS

USE OF KNURLED

NUT IS OPTIONAL

SERIES 42

1" Diameter, 1 Amp, PC Mount

OF FRONT SUPPORT

PLATE MOUNTING

HOLES

C

L

.375

(9,53)

TyP.

.750

(19,05)

TyP.

.492

(12,50)

.500

(12,7)

TyP.

.250

(6,35)

TyP.

.110 (2,79)

.174 (4,42) TyP.

C

L OF REAR

SUPPORT

PLATE

MOUNTING

HOLES

C

L OF BASE

TERMINAL

MOUNTING

HOLES

C

L COMMON

TERMINAL

MOUNTING

HOLES

SHAFT END

.174 (4,42)

TyP.

SHAFt AND PANEL SEAL: Srs. 42 & 44

Standard Style

The Series 42/44 Styles, which include the letter "S" with

the exception of style "HS", are watertight sealed to the

mounting panel by utilizing the panel seal kit. These switches

are built with a front plate that does not have a non-turn tab.

The panel seal kit consists of a grooved hex nut, a keyed

washer and a keyed panel seal. The grooved hex nut is

assembled to the switch bushing. The keyed washer is slid

down the bushing slot and seated into the hex nut groove.

The seal is likewise assembled to the bushing and hex nut.

The keyed washer is required to provide seal integrity in the

bushing slot. When assembled to the panel, the grooved

nut, backing washer and seal require the same space as a

normal mounting nut. Hence, the seal kit does not alter the

dimensions. Panel seal kit includes a non-turn washer to

be used into a blind hole in the back panel. For panel seal

kit part dimensions, see Accessories. Style "HS" switches

use a similar sealing method, except the integral assembly

nut retains the panel seal. All sealed style switches are

provided with a shaft to bushing internal seal.

FEAtuRES

• Satisfies High Current Board Level

Applications

• 36° Angle of Throw Permits up to

Ten Positions

• UL Recognized Versions

For style 44M30, use 44D30 initially

For style 42u36, use 42uD36

For style 44u30, use 44uD30