General Machine Products 89010 Breeze Micro Fiber Cable Blowing Machine User Manual

Page 34

Page 34 of 43

General Machine Products Co., Inc.

The torque control setting will allow the cable to be installed efficiently and without damage.

It is of vital importance that the torque setting is made with great care, a little time spent un-

derstanding the way to arrive at the optimum settings will save time and frustration during

the installation. There are two stages to arriving at the correct torque setting they are de-

scribed below.

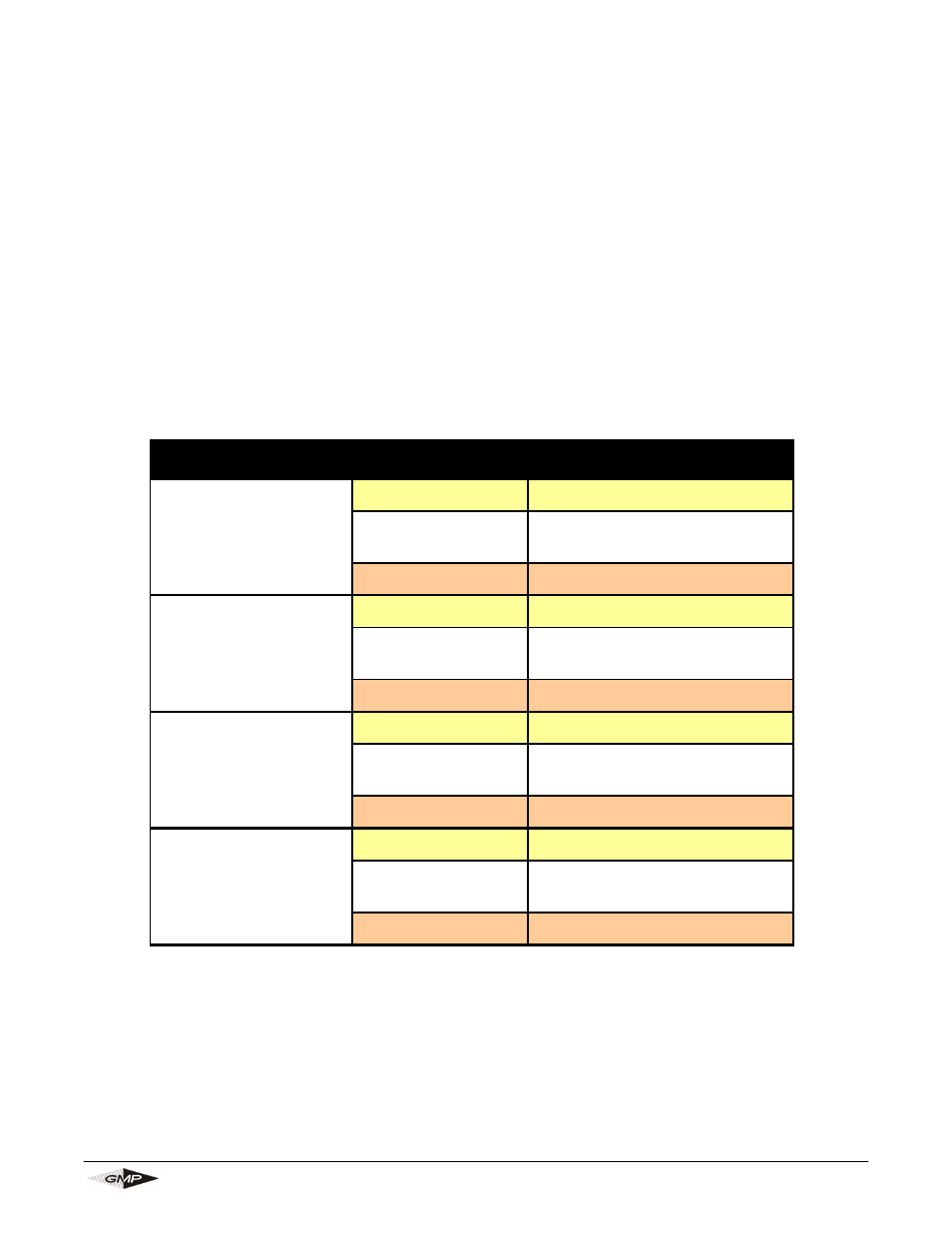

1. Establish the stiffness coefficient from the table below: the stiffness coefficient is a figure

used to represent the diameter and the stiffness of a cable. This figure is only relevant in the

context of setting the torque, it has no other relevance. The higher the U figure the stiffer the

cable. There is a degree of subjectivity about determining the cable stiffness. What is low

stiffness? What is high stiffness? Determining this (the stiffness) relies upon the user having

some familiarity with bundled optical fiber cables, this will give the experience to assess

whether the cable has low, medium or high stiffness. For instance a small diameter cable

with high stiffness may be less stiff than a large cable with medium stiffness. The table re-

flects this. If there is any doubt, in the first instance err on the low side, i.e. select a lower U

figure.

2. Assess the coefficient of friction of the cable insulation (the outer coating). Is it low or

high? Once again this relies on the user having some experience with bundled optical fiber

cables. As a guide, if the surface feels smooth and dry the coefficient of friction will be low, if

you slide your hand over the surface does it snatch your flesh? If it does the coefficient of

friction will be high. As above, if there is any doubt, err on the low side i.e. select a lower co-

efficient of friction.

Cable diameter Cable stiffness Stiffness coefficient (U)

Low

U1

0.078” – 0.138”

(1.98 - 3.50 mm)

Medium

U1

High

U2

Low

U1

0.138” – 0.197”

(3.5 - 5.00 mm)

Medium

U2

High

U3

Low

U2

0.197” – 0.256”

(5.00 - 6.50 mm)

Medium

U3

High

U5

Low

U2

0.256” – 0.315”

(6.50 - 8 mm)

Medium

U4

High

U6