Caution – Bryant Air Conditeners 180A User Manual

Page 4

4

Table 2 – Accessory Usage

Accessory

REQUIRED FOR

LOW---AMBIENT COOLING

APPLICATIONS

(Below 55°F/12.8_C)

REQUIRED FOR LONG LINE

APPLICATIONS*

REQUIRED FOR SEA COAST

APPLICATIONS

(Within 2 miles/3.22 km)

Accumulator

No

No

No

Compressor Start Assist Capacitor and

Relay}

Standard on 187A models.

Not required for 180A models.

Standard on 187A models.

Not required for 180A models.

Standard on 187A models.

Not required for 180A models.

Crankcase Heater

Standard

Standard

Standard

Evaporator Freeze Protection

Standard with Evolution Control

(Low Ambient not allowed with non---

communicating Thermostat)

No

No

Liquid Line Solenoid Valve

No

No

No

Low---ambient Control

Standard with Evolution Control (Low

Ambient not allowed with non---com-

municating thermostat)

No

No

Puron Balance Port Hard Shut---off TXV

Yes

{

Yes{

Yes{

Winter Start Control

Standard with Evolution Control (Low

Ambient not allowed with Non---Com-

municating Thermostat)

No

No

Support Feet

Recommended

No

Recommended

* For Tubing Set lengths between 80 and 200 ft. (24.38 and 60.96 m) horizontal or 20 ft. (6.10 m) vertical differential (250 ft./76.2 m Total Equivalent Length),

refer to the Residential Piping and Long Line Guideline for Air Conditioners and Heat Pumps using Puron® Refrigerant.

{

Required on all indoor units. Standard on all new Puron fan coils and furnace coils.

}

Information is specific to 187A and 180A models.

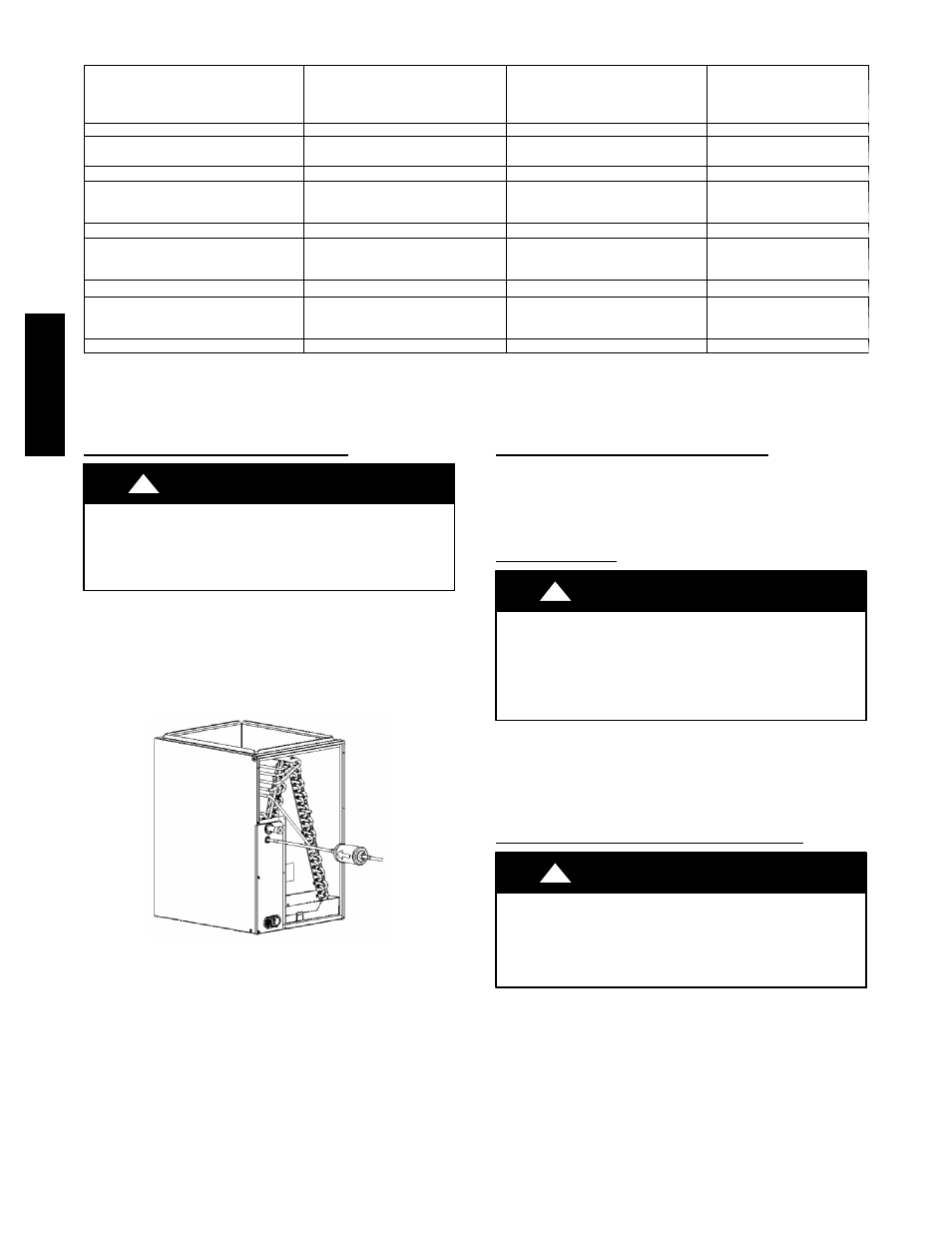

Install Liquid--Line Filter Drier Indoor

CAUTION

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage

or improper operation.

Installation of filter drier in liquid line is required.

Refer to Fig. 3 and install filter drier as follows:

1. Braze 5 in. (127 mm) liquid tube to the indoor coil.

2. Wrap filter drier with damp cloth.

3. Braze filter drier to above 5 in. (127 mm) liquid tube. Flow

arrow must point towards indoor coil.

4. Connect and braze liquid refrigerant tube to the filter drier.

A05178

Fig. 3 -- Liquid Line Filter Drier

Refrigerant Tubing Connection Outdoor

Connect vapor tube to fitting on outdoor unit vapor service valves

(see Table 1.) Connect and braze the 3/8 in. coupling (provided

with the filter drier) to the liquid service valve and connect and

braze the liquid tubing to the other end of this coupling. Use

refrigerant grade tubing.

Sweat Connection

CAUTION

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

S

Use a brazing shield

S

Wrap service valves with wet cloth or heat sink material.

Use refrigerant grade tubing. Service valves are closed from factory

and ready for brazing. After wrapping service valve with a wet

cloth, braze sweat connections using industry accepted methods

and materials. Consult local code requirements. Refrigerant tubing

and indoor coil are now ready for leak testing. This check should

include all field and factory joints.

Evacuate Refrigerant Tubing and Indoor Coil

CAUTION

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Never use the system compressor as a vacuum pump.

180A

/187A