Thermistor curve – Bryant Air Conditeners 180A User Manual

Page 11

11

Table 5 – 2---Stage Compressor

(Winding Resistance at 70_F ± 20_ / 21.11_C ± 11.11_C)

Winding

187A024

187A036

187A048

187A060

Start (S---C)

2.74

1.98

1.55

0.74

Run (R---C)

0.80

0.75

0.48

0.36

Winding

180A024

180A036

180A048

180A060

Start (S---C)

1.40

1.29

1.52

0.60

Run (R---C)

1.32

0.89

0.64

0.49

MAJOR COMPONENTS

2--Stage Control

The 2--stage control board controls the following functions:

-- Low-- and high--stage compressor contactor operation

-- Outdoor fan motor operation

-- Low ambient cooling

-- Crankcase heater operation

-- Compressor external protection

-- Pressure switch monitoring

-- Time delays

-- On 187A models, start relay and capacitor

Field Connections

On 187A models with non--communicating (non--Evolution)

system, the 2--stage control receives 24vac low--voltage control

system inputs through the R, C, Y1, and Y2 connections located at

the bottom of the control board (see Fig. 6). The 187A can be

controlled using a standard 2--stage thermostat or Evolution User

Interface.

All 180A models are part of a complete Evolution communicating

system and use only the ABCD connections on the circuit board.

The 180A must be controlled using an Evolution User Interface for

proper equipment staging and operation

2--Stage Compressor

The 2--stage compressor contains motor windings that provide

2--pole (3500 RPM) operation. Refer to Table 5 for correct winding

resistance.

Compressor Internal Relief

The compressor is protected by an internal pressure relief (IPR)

which relieves discharge gas into compressor shell when

differential between suction and discharge pressures exceeds 500 --

550 psi on 187A models and 550 -- 625 psi on 180A models. The

compressor is also protected by an internal overload attached to

motor windings.

Compressor Control Contactors

The contactor(s) have a 24 volt coil. The electronic control board

controls the operation of the appropriate contactors.

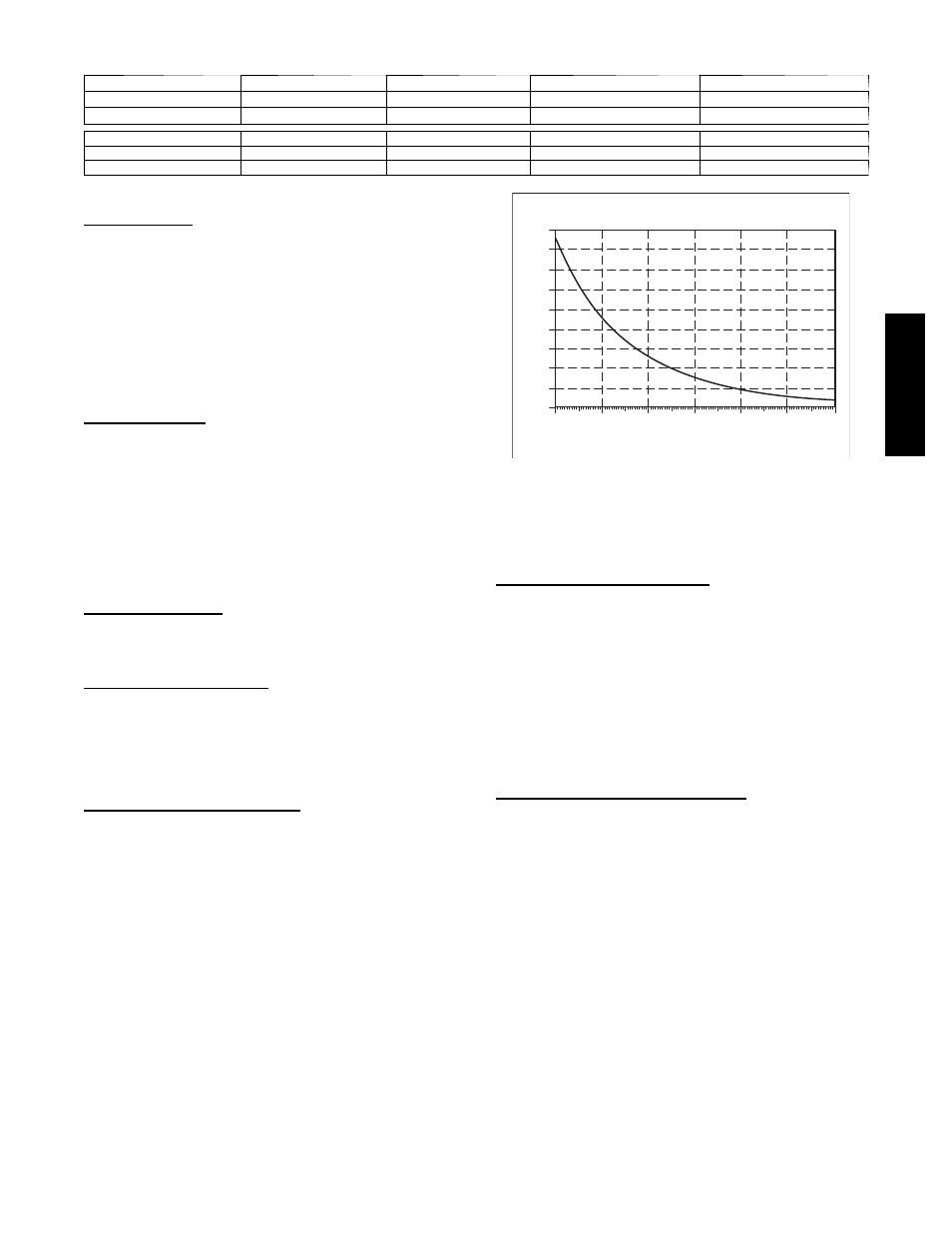

TEMPERATURE THERMISTORS

Thermistors are electronic devices which sense temperature. As the

temperature increases, the resistance decreases. Thermistors are

used to sense outdoor ambient (OAT) and coil temperature (OCT).

Refer to Fig. 7 for resistance values versus temperature.

If the outdoor ambient or coil thermistor should fail, the control

will flash the appropriate fault code (see Table 6.)

0

10

20

30

40

50

60

70

80

90

0

(-17.77)

20

(-6.67)

40

(4.44)

60

(15.56)

80

(26.67)

100

(37.78)

120

(48.89)

TEMPERATURE °F (°C)

RESISTANCE (KOHMS)

THERMISTOR CURVE

A08054

Fig. 7 -- Resistance Values Versus Temperature

IMPORTANT: Outdoor air thermistor and coil thermistor are

factory mounted in the final locations. Check to insure thermistors

are mounted properly per Fig. 8 and Fig. 9.

Thermistor Sensor Comparison

The control continuously monitors and compares the outdoor air

temperature sensor and outdoor coil temperature sensor to ensure

proper operating conditions. The comparison is:

S

If the outdoor air sensor indicates ≥ 10_F/5.56_C warmer than

the coil sensor (or) the outdoor air sensor indicates ≥

20_F/11.11_C cooler than the coil sensor, the sensors are out of

range.

If the sensors are out of range, the control will flash the appropriate

fault code as shown in Table 6.

The thermistor comparison is not performed during low ambient

cooling or defrost operation.

Failed Thermistor Default Operation

Factory defaults have been provided in the event of failure of

outdoor air thermistor and/or coil thermistor.

If the OAT sensor should fail, low ambient cooling will not be

allowed and the one--minute outdoor fan off delay will not occur.

If the OCT sensor should fail, low ambient cooling will not be

allowed.

180A

/187A