Operation – Flint & Walling Constant Pressure Pumping Stations - Add-On Kit User Manual

Page 3

4

(FW1442)

95 North Oak St. • Kendallville, IN 46755 • 1-800-742-5044

5

(FW1442)

95 North Oak St. • Kendallville, IN 46755 • 1-800-742-5044

• Install provided heaters onto starter. Note: the heat-

ers provide over current protection for the motor.

This starter with heaters installed does not provide

protection from short circuits.

• Connect Starter L1 and Overload relay terminal X2

with wire rated for system power and route enough

wire to connect them to Drive terminals T5 & T6

respectively.

• IMPORTANT: For priming purposes only, temporarily

wire nut the wires together instead of connecting

to T5 and T6. After full prime, connect to T5 and T6.

• Connect Starter L2 to Coil terminal W with wire

rated for system power.

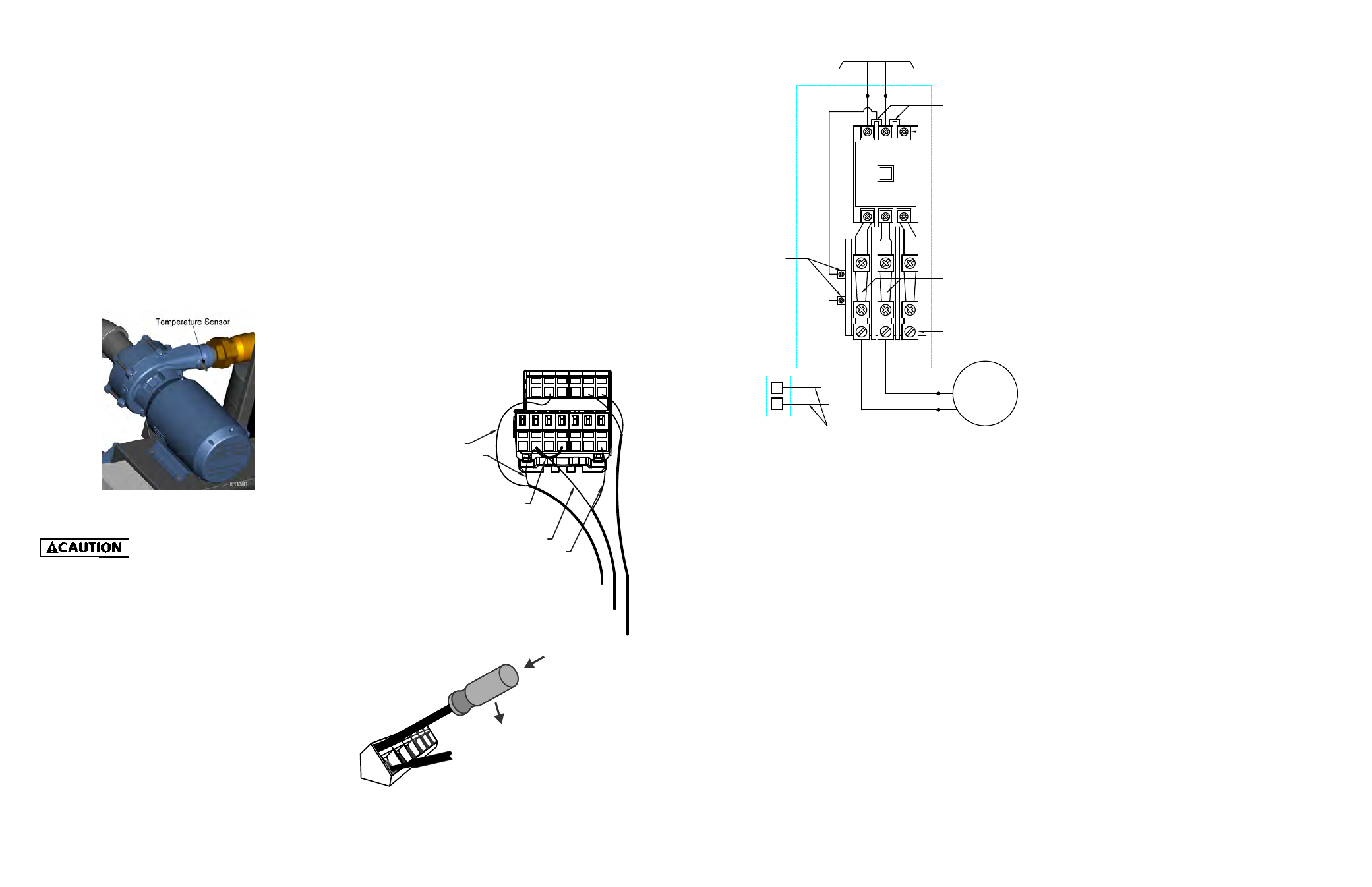

• Install temperature sensor wire provided onto ¼”

quick connect terminals of the temperature sensor

located near the pump discharge (Figure 2) to drive

terminals B2 & B7 (Figure 3) (Note: The new tem-

perature sensor wires will share B2 & B7 drive termi-

nals with factory installed wires.)

figure 2 temperature Sensor location

Operation

Unit must be full of fluid before

operating. Do not run dry, or against a closed

discharge. Do not pump dirty water or abrasive

liquids. To do so will cause pump failure and will

void the warranty.

vAlveS

The suction inlet valve should be in the full open posi-

tion and hose bib valve should be partially open, allow-

ing some back pressure to be exerted against the pump

when starting up. Close hose bib valve after priming up

is completed.

PrIMInG

IMPORTANT: Before starting the pump it is absolutely

necessary that both pumps and the suction pipe be

completely filled with water. Before the entire duplex

pump system is fully operational, the single phase

pump, needs to be completely primed and run before

returning power to the variable frequency drive.

IMPORTANT: Before priming, verify control wires are

temporarily connected with a wire nut instead of being

connected to drive terminals T5 & T6.

PrIMInG Of PreSSure BOOSt InStAllAtIOnS

Priming is simple when pump is connected to a pressure

source such as a city main or above ground tank filled

to a level of 4 ft. above pump inlet.

1. Open inlet valves fully on suction and open hose

bib on skid system manifold.

2. To relieve trapped air, allow water supply to run a

minimum of 2 minutes before starting the pump.

3. Turn on power to the single phase pump and run

no longer than two (2) minutes. Unit should build

pressure & pump water. If not, repeat the sequence

above.

4. Once all air has been evacuated and the pump has

been primed, close hose bib and turn off power.

5. IMPORTANT: Once priming has been completed &

power has been turned off, remove the wire nut

connecting control wires and connected them to

drive terminals T5 & T6 (Figure 3).

Temperature Sensor Wire - Red

Temperature Sensor Wire - Black

Transducer Wire - Black

Transducer Wire - Red

Tr

ansduc

er C

able

Star

ter

Con

trol W

ires

Temper

atur

e S

ensor C

able

Jumper Wire

IL1140

B7

B6

B5

B4

B3

B2

B1

T6

T5

T4

T3

T2

T1

1

2

figure 3 Drive Control Circuit terminals

IL1139

L1 L2 L3

T1

T2

T3

X2

NC

Pump

Motor

To Properly Protected

Disconnect Circuit

Motor Starter

L1

L2

Drive

Terminals

T5

T6

Line Terminals

Coil Terminals

Install Heaters

Load Terminals

Overload Relay

Terminals

Starter Control Wires

figure 4 Starter Wiring

PrIMInG fOr SuCtIOn lIft InStAllAtIOnS

On suction lift applications prime the unit as follows:

1. Remove priming plug from service tee and fill pump

and suction pipe with water.

2. Jog the pump motor by applying power on and off

several times to free air trapped inside the pump.

3. After jogging the pump, refill with water and

repeat the priming sequence several times to be

sure all air is out of the pump and suction pipe.

4. Open hose bib on skid system manifold, start the

pump and run no longer than two (2) minutes. Unit

should build pressure & pump water. If not, repeat

the sequence above.

NOTE: On first use of pump, it may be necessary to re-

prime the unit three (3) or four (4) times before all air is

out of the suction pipe.

5. Once all air has been evacuated and the pump has

been primed, close hose bib and turn off power.

6. IMPORTANT: Once priming has been completed &

power has been turned off, remove the wire nut

connecting control wires and connected them to

drive terminals T5 & T6 (Figure 3).

StArt-uP PrOCeDure

Once the preceding instructions have been completed,

the entire system can be started:

1. Verify that all values installed on the intake side of

the pumps are open & the isolation value is closed

if installed on the discharge side of the system.

2. Verify that the 3-phase pump is primed. For gravity

fed systems, this can be accomplished by opening

hose bib valve installed on the system manifold to

allow the water pressure to push out the air from

the pump. For suction lift systems, fill the pump

and intake piping with external water source until

water begins coming out the open hose bib valve.

3. Close hose bib valve.

4. Supply electrical power to Pump Station by turning

on the user installed disconnect to the ON position

and allow system to pressurize and check for leaks

on plumbing installed.

5. Once pressure has been established, partially crack

open the station isolation valve (while maintaining

pressure) and open valves farthest away from pump

station to bleed air out of the system & piping

6. When the whole Main Line has been bled of air,

fully open the discharge isolation valve.

7. Supply electrical power to single phase pump by

truing on the user installed disconnect to the ON

position. When demand exceeds the capacity of the

three phase pump, the single phase motor will start

up for a minimum of one minute.

8. During the first few hours of operation, inspect the

pump, piping and any auxiliary equipment used in

connection with the unit.

9. Check for leaks, excessive vibration or unusual

noises.

MAIntenAnCe:

For proper maintenance of the pump, please follow

instructions in enclosed End suction centrifugal pumps

instructions FW0300/134984.