Ab c – EUCHNER CET-AX User Manual

Page 2

Operating Instructions Read Head CET-AX with Guard Locking and Guard Locking Monitoring

EUCHNER GmbH + Co. KG Kohlhammerstraße 16 D-70771 Leinfelden-Echterdingen Tel. +49/711/75 97-0 Fax +49/711/75 33 16 www.euchner.de [email protected]

Emergency unlocking (can be retrofitted)

Using emergency unlocking

Important:

The door must not be under tension when emer-

gency unlocking is actuated.

f

Turn emergency unlocking clockwise until it clicks

into place.

¨

The safety device can be opened

To reset, press the detent bolt inward using a small

screwdriver or similar tool and turn the emergency

unlocking back.

Escape release (optional)

The escape release is used to open a locked safety

guard from the inside (see dimension drawing in the

section Technical data).

Fit escape release such that operation, inspection

and maintenance are possible.

Using the escape release

f

Press the red release knob to the stop

¨

The safety device can be opened

Pull the knob out again to reset.

Wire front release (optional)

The wire front release permits remote release of

the guard locking via a pull rope. Flexible routing of

the pull rope permits release of the guard locking

in inaccessible installation situations.

Lockout mechanism (optional)

Important:

f

The lockout mechanism is not a safety function.

f

The correct function must be checked at regular

intervals.

The lockout mechanism can be used to prevent

maintenance personnel from being unintentionally

locked in the danger area, for example.

In locked position, the lockout mechanism prevents

activation of guard locking. The lockout mechanism

can be secured in locking position with up to three

locks. The mechanical release can still be used.

Using the lockout mechanism

Important:

Deactivate guard locking and open the safety door

before using the lockout mechanism.

Before entering the danger area:

1. Open the door

2. Press button, move lockout mechanism to

locking position (Figure 1 A and B) and secure

with lock (Figure C)

¨

Guard locking cannot be activated, and it must

not be possible to start the machine. Important:

Test this before entering the danger area.

Resetting the lockout mechanism:

1. Open the safety door if necessary

2. Remove the lock

3. Move lockout mechanism to basic position

(Figure 1 A)

Mounting

Caution:

Safety switches must not be bypassed (bridging

of contacts), turned away, removed or otherwise

rendered ineffective.

f

On this topic pay attention in particular to the

measures for reducing the possibility of bypassing

according to EN 1088:1995.A2:2008, Sec. 5.7.

Caution:

Risk of damage to equipment as a result of incorrect

installation. Safety switches must not be used as a

mechanical end stop.

f

Fit an additional end stop for the movable part of

the safety guard.

f

Observe the min. door radii (see Figure 3).

f

Ensure that the actuator contacts the slide in the

designated area (see figure below). Marks on

the slide specify the prescribed approach zone.

Note the following points:

f

Actuator and safety switch must be easily acces-

sible for inspection and replacement.

f

The switching operation must only be triggered by

the specific actuator designated for this purpose.

f

Actuator and safety switch must be fitted so that

f

the actuator is positively mounted on the safety

guard, e.g. by using the safety screws included.

f

they cannot be removed or tampered with using

simple means.

f

the active faces of the actuator and the safety

switch are parallel to each other (see Figure 3).

f

the actuator is fully inserted into the switch recess

when the safety guard is closed (see Figure 3).

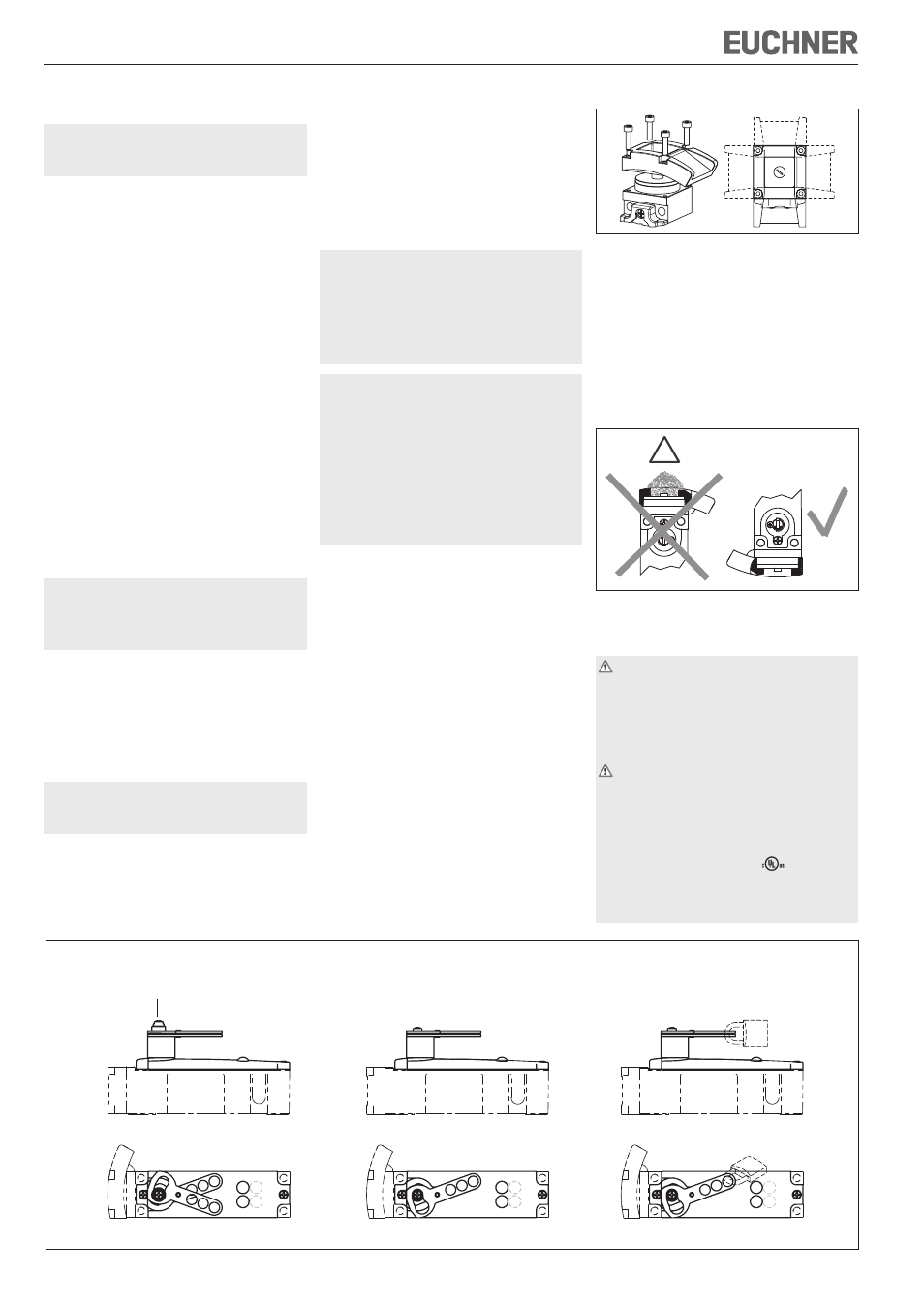

Changing the approach direction

Locking function not active

Locking function active

Locking function active

and secured

Pushbutton

Push button and

align lever

Fit lock

A

B

C

Figure 1: Function of lockout mechanism

Figure 2: Changing the approach direction

f

Remove the screws from the read head.

f

Set the required direction.

f

Tighten the screws with a torque of 1.5 Nm.

Protection against environmental effects

A lasting and correct safety function requires that the

actuating head must be protected against foreign

bodies such as swarf, sand, blasting shot, etc.,

which can become lodged in the recess. For this

purpose, the read head should be installed with the

actuating head facing down.

Subject to technical modifications, no r

esponsibility is accepted for accuracy of this information.

© EUCHNER GmbH + Co. KG

098069-16-11/12 (translation of the original operating instructions)

Cover the actuating head, the actuator and the rating

plate during painting work!

Electrical connection

The read head CET is only allowed to be used in

combination with a suitable EUCHNER connec-

tion cable (see Table 1). The connection cable

contains two screened cores for the signal

from the read head. This screening must not be

interrupted on the route to the evaluation unit

or earthed at any other point (see Figure 8).

All the electrical connections must either be

isolated from the mains supply by a safety

transformer according to IEC EN 61558-2-6

with limited output voltage in the event of a

fault (PELV), or by other equivalent isolation

measures.

For use and operation as per the

requirements,

a power supply with the feature "for use in class 2

circuits" must be used. The same requirement ap-

plies to the safety outputs.

!