EUCHNER CET-AX User Manual

ᕃᕄ ᕅ

Operating Instructions Read Head CET-AX with Guard Locking and Guard Locking Monitoring

Correct use

Series CET-AX read heads are operated in combi-

nation with an evaluation unit in the system family

CES-AZ. In this combination the read head CET-AX

is an electromagnetic interlock device with guard

locking and guard locking monitoring.

In combination with a safety guard and the machine

control, this safety system prevents the safety guard

from being opened while a dangerous machine

movement is being performed.

For the control system, this means that

f

starting commands which cause hazardous situ-

ations must become active only when the safety

guard is in protective position and the guard lock-

ing is in locked position. The locked position of

the guard locking must be released only when the

hazardous situation is no longer present.

Before safety components are used, a risk as-

sessment must be performed on the machine in

accordance with

f

EN ISO 13849-1, Safety of machinery. Safety re-

lated parts of control systems. General principles

for design, Annex B

f

EN ISO 12100, Safety of machinery - General

principles for design - Risk assessment and risk

reduction

f

IEC 62061, Safety of machinery. Functional safety

of safety-related electrical, electronic and program-

mable electronic control systems.

Correct use includes compliance with the relevant

requirements for installation and operation, in

particular

f

EN ISO 13849-1, Safety of machinery. Safety re-

lated parts of control systems. General principles

for design

f

EN 1088, Safety of machinery. Interlocking

devices associated with guards. Principles for

design and selection

f

EN 60204-1, Safety of machinery. Electrical equip-

ment of machines. General requirements.

The read head is only allowed to be operated in

conjunction with the intended EUCHNER CET actua-

tors and the related connection components from

EUCHNER. On the use of different actuators or

other connection components, EUCHNER provides

no warranty for safe function.

The read head CET is only allowed to be used in

combination with a system family CES-AZ evaluation

unit (see Table 2).

Important:

f

The user is responsible for the integration of

the device into a safe overall system. For this

purpose, the overall system must be validated,

e.g. according to EN ISO 13849-2.

f

Correct use requires observing the permissible

operating parameters (see Technical data).

f

If a product data sheet is included with the

product, the information on the data sheet ap-

plies in case of discrepancies with the operating

instructions.

f

The PL that can be achieved depends on the

installation position and the evaluation unit used.

Pay attention to the information in Table 2.

Exclusion of liability and warranty

In case of failure to comply with the conditions for

correct use stated above, or if the safety instruc-

tions are not followed, or if any servicing is not

performed as required, liability will be excluded and

the warranty void.

Safety precautions

Safety components fulfill personal protection func-

tions. Incorrect installation or tampering can lead to

fatal injuries to personnel.

Check the safe function of the safety guard par-

ticularly

f

after any setup work

f

after the replacement of a system component

f

after an extended period without use

f

after every fault

Independent of these checks, the safe function of the

safety guard should be checked at suitable intervals

as part of the maintenance schedule.

Fatal injury due to incorrect connection or incor-

rect use.

f

Safety switches must not be bypassed (bridg-

ing of contacts), turned away, removed or

otherwise rendered ineffective. On this topic

pay attention in particular to the measures

for reducing the possibility of bypassing from

EN 1088:1995+A2:2008, Section 5.7.

The device may be installed and put into opera-

tion only by authorized experts

f

who are familiar with the correct handling of

safety components

f

who are familiar with the applicable EMC

regulations

f

who are familiar with the applicable regula-

tions on health and safety and accident

prevention

f

who have read and understood the operating

instructions and the system manual.

The switching operation must only be trig-

gered by actuators specifically provided for

this purpose (see Table 3) which are positively

connected to the safety guard.

Function

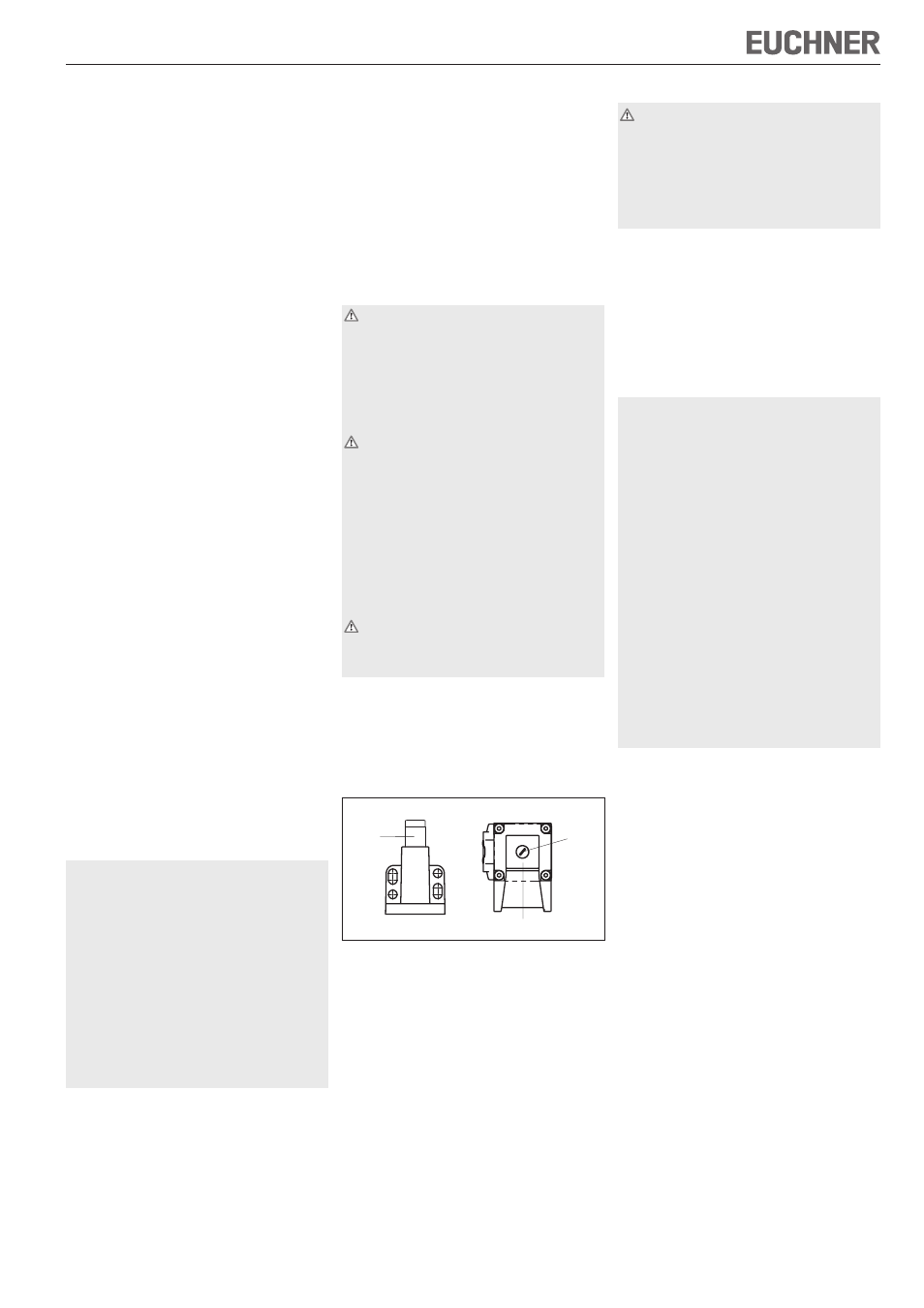

In the read head there is a lift tappet (1) that contains

the transponder (see Figure 1). The actuator has a

spring-mounted guard locking pin (2) in which there

is a CES actuator. The guard locking is active if the

lift tappet is retracted and the guard locking pin is

in the recess (3) on the read head.

f

Version CET2, guard locking by solenoid force

The safety guard can be opened immediately in

the event of interruption of the solenoid power

supply! Usage only in special cases in accor-

dance with strict evaluation of the accident risk

(see DIN EN 1088 (1995), Section 5.5)!

Example: If the risk of accidental locking inside

a safety guard during a power failure is higher

than the risk of ineffective guard locking.

The lift tappet is initially extended by spring force.

The spring force on the guard locking pin is not

sufficient to press down the lift tappet. Only when

the guard locking solenoid is also switched on does

the lift tappet retract. The guard locking is active.

The guard locking operates in accordance with the

open-circuit current principle.

The safety door can be opened as long as the lift tap-

pet is held in the extended position by spring force.

Releases

Important:

f

The releases are not safety functions.

f

The machine manufacturer must select and use

a suitable release (escape release, emergency

unlocking, etc.) for a specific application. A risk

assessment appraisal is required for this purpose.

It may be necessary to take specifications from

a product standard into account.

f

The releases must not be used to lock the switch

during maintenance work to prevent activation of

guard locking, for example.

f

The correct function must be checked at regular

intervals.

f

Loss of the release function due to mounting

errors or damage during mounting.

f

Check the release function every time after

mounting.

f

Loss of the release function due to tension on

the actuator. The door must not be under tension

during release.

f

Observe the notes on the enclosed data sheets.

Mechanical release and mechanical key

release (can be retrofitted)

The mechanical release can be used to unlock guard

locking, irrespective of the state of the solenoid.

Using mechanical release

1. Unscrew locking screw

2. Using a screwdriver, turn the mechanical

release by around 180° in the direction of the

arrow

¨

The safety device can be opened

The mechanical release must be returned to its

original position and sealed after use (for example

with sealing lacquer).

Using mechanical key release

On devices with mechanical key release (can be

retrofitted), simply turn the key to unlock. For mount-

ing, see the mechanical key release supplement.

Figure 1: Read head and actuator

f

Version CET1, guard locking by spring force

The lift tappet is pressed into the locked position

by the force of the spring for the guard locking pin

in the actuator and unlocked electromagnetically by

the read head. The guard locking functions in accor-

dance with the closed-circuit current principle. The

locked safety guard cannot be opened immediately

in the event of interruption of the power supply to

the solenoid.

The actuator's guard locking pin cannot be moved

out of the recess and the door is locked in the closed

position as long as the lift tappet is pressed down

by the guard locking pin.

When the operating voltage is present at the lock-

ing solenoid, the lift tappet is extended and lifts the

actuator's guard locking pin above the edge of the

recess. The safety door can then be opened.

ᕃ

ᕄ

ᕅ

Actuator

Read head