Operating instructions safety hinge esh – EUCHNER ESH User Manual

Page 3

Operating Instructions Safety Hinge ESH

Correct use

The safety hinges ESH are safety devices for monitor-

ing movable safety guards, such as doors or covers

on machinery or systems.

In combination with a separating safety guard, this

safety component prevents the safety guard from

being opened while a dangerous machine movement

is being performed. A stop command is triggered if

the safety guard is opened during the dangerous

machine function.

The safety switches series ESH comply with the

regulations of EN 60947-5-1, Annex K and comply

with the requirements of the employers' liability insur-

ance associations for machines, installations and

personnel protection.

Before safety switches are used, a risk assessment

must be performed on the machine in accordance

with

f

EN ISO 13489-1, Safety of machinery. Safety re-

lated parts of control systems. General principles

for design

f

EN ISO 14121, Safety of machinery. Risk assess-

ment. Principles

f

IEC 62061, Safety of machinery. Functional safety

of safety-related electrical, electronic and program-

mable electronic control systems.

Correct use includes compliance with the relevant re-

quirements for installation and operation, in particular

f

EN ISO 13489-1, Safety of machinery. Safety re-

lated parts of control systems. General principles

for design

f

EN 1088, Safety of machinery. Interlocking devices

associated with guards. Principles for design and

selection

f

EN 60 204-1, Safety of machinery. Electrical equip-

ment of machines. General requirements.

Important:

f

The user is responsible for the integration of the

device in a safe overall system. For this purpose

the overall system must be validated, e.g. in ac-

cordance with EN ISO 13849-2.

f

If the simplified method according to section 6.3

EN ISO 13849-1:2008 is used for validation, the

Performance Level (PL) may be reduced if several

devices are connected one after the other.

f

If a product data sheet is included with the product,

the information on the data sheet applies in case

of discrepancies with the operating instructions.

Safety precautions

Safety switches fulfill a personal protection function.

Incorrect installation or tampering can lead to severe

injuries to personnel.

Safety components must not be bypassed

(bridging of contacts), turned away, removed

or otherwise rendered ineffective.

On this topic pay attention in particular to the mea-

sures for reducing the possibility of bypassing from

EN 1088:1995+A2:2008, sec. 5.7.

A complete safety-oriented system generally

consists of several signaling devices, sensors,

evaluation units and concepts for safe shutdown.

The manufacturer of a machine or installation is

responsible for correct and safe overall function.

Mounting, electrical connection and setup only

by authorized personnel.

Function

The safety switch signals that the safety guard is

closed.

The switching state is additionally indicated in the

window (default setting on delivery closed).

The switch does not perform guard locking!

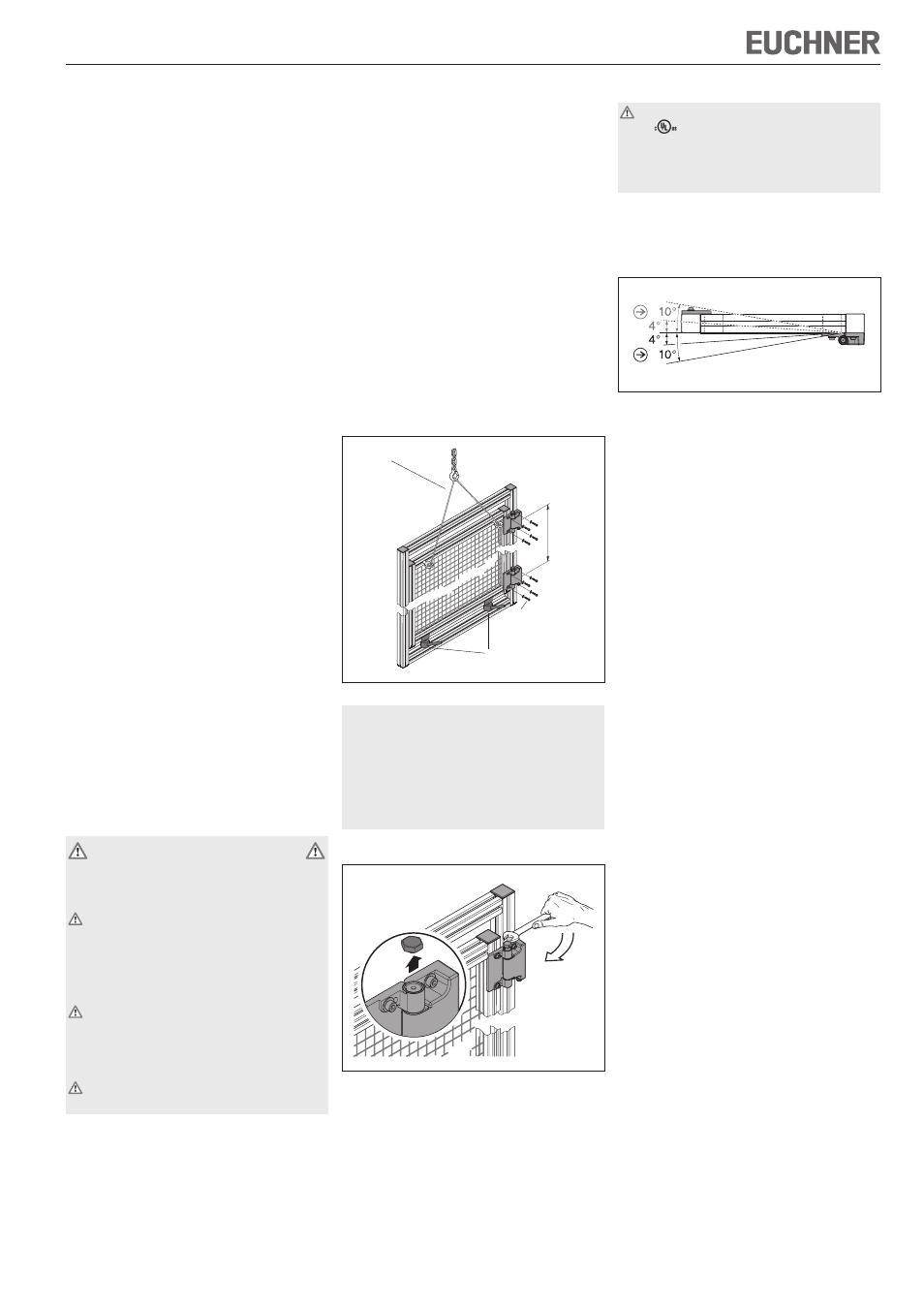

Installation

Safety switches must be arranged such that they are

adequately secured against movement.

The maximum load given must not be exceeded.

The safety hinge is not allowed to be used as a

mechanical limit for the door pivot radius.

You can obtain suitable plain hinges without switches

from EUCHNER under order no. 096 007.

To meet these requirements:

f

The fixings must be reliable and must also require

the use of a tool to undo them.

f

Mount the safety switch positively.

f

Fit switches using M6 screws.

Proceed as follows:

1. Fasten hinges to the frame. The fastening points

for the two hinges must be as far apart as pos-

sible. The axes around which the hinges pivot

must be exactly in a line.

2. Move door to the required position and secure

against slipping or falling.

3. Fit door to the hinges.

4. Fix door in closed position.

Warning: risk of injury due to slipping or falling on

shearing off the hex head. Ensure you are standing

safely and do not tighten hex head with a jerking

action.

Caution: do not move door while tightening the

shear screw, as then the operating point will change.

The operating point is already fixed on tightening. It

is not possible to correct the position later.

5. Screw in shear screw to the stop. Slowly tighten

further until the hex head shears off.

¨

The operating point is fixed permanently in this

position.

Electrical connection

For use and applications as per the requirements

of

, a class 2 power supply or a class 2

transformer according to UL1310 or UL1585

must be used. As an alternative, a low voltage

power supply according to UL508 table 32.1

can be used.

f

Connect M12/5-pin plug connector.

f

You can obtain suitable connection cables from

EUCHNER under order no. 073461.

Setup

l = max.

4 x M6

Support

Support/adjustment aid

f

Mechanical function test

1. Open door and check operating point. The hinge

must switch at the latest 4° from the closed posi-

tion (fixing position). The switching contacts are

positively opened after approx. 10°.

2. Check whether the door moves freely.

f

Electrical function test

1. Close the safety guard.

2. Start the machine.

3. Check whether the machine stops when the

safety guard is opened.

4. Switch off the machine.

5. Open the safety guard. The machine must not

start when the safety guard is open!

When the safety guard is open, the safety switch must

be actuated in any safety guard position.

Protection against environmental effects

A lasting and correct safety function requires pro-

tection against the penetration of foreign bodies

such as swarf, sand, blasting shot, etc. Only use

solvent-free and acid-free cleaning agents to clean

the safety switch!

Inspection and service

No servicing is required. but regular inspection of

the following is necessary to ensure trouble-free

long-term operation:

f

correct switching function

f

secure mounting of components

f

dirt and wear

f

loose plug connectors.

If damage or wear is found, the complete switch

must be replaced. Replacement of individual parts

or assemblies is not permitted!

Note: The year of manufacture can be seen in the

bottom, right corner of the rating plate.

Exclusion of liability under the following

circumstances

f

incorrect use

f

non-compliance with safety regulations

f

installation and electrical connection not performed

by authorized personnel

f

failure to perform functional checks.