Startup procedure – Det-Tronics U7698A, B, C, E Unitized Frequency IR Detector/Controller User Manual

Page 10

5.

Route the field wiring through the detector conduit

entry.

6.

Attach the wires to the appropriate screw terminals

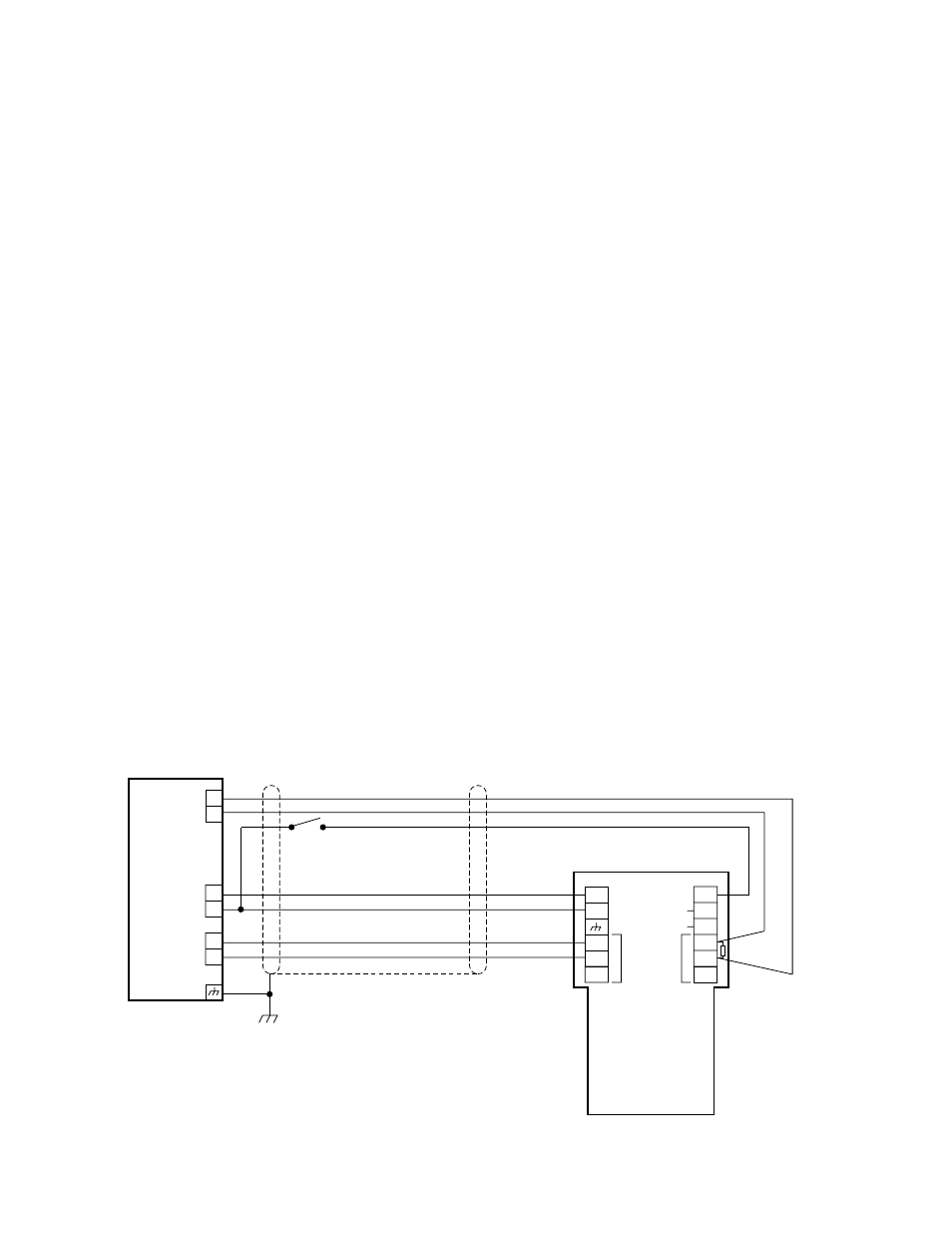

on the terminal block. Refer to Figure 8 for wiring a

single unit and Figure 9 for a multiple configuration.

Connect the shield to earth ground at the power

source. Do not ground the shield at the

detector/controller housing (unless required by local

codes).

7.

To wire the

oi test switches, connect a normally

open switch between the negative (–) side of the dc

power source and the terminal marked “

oi” on the

detector terminal block. Each detector must have

its own

oi test switch.

8.

Check all field wiring to be sure that the proper con-

nections have been made. If conduit is used, pour

the conduit seals and allow them to dry.

9.

Remove the IR module from its shipping package.

10. The alarm relay is factory programmed for latching

operation. To program the relay for non-latching

operation, a jumper plug that is located on the IR

module must be re-positioned. See Figure 6 to

locate the jumper plug. Refer to the label on the

side of the IR module to determine the correct posi-

tion for the jumper plug.

11. Thread the wire leads and keyed connector plug

through the slotted opening on the IR module. Plug

the IR module into the two banana plugs in the bulk-

head.

NOTE

The two oi lamps should be at the top of the detec-

tor (when viewed from the front) and the opening

on the oi ring should be directly opposite the test

lamps. This will ensure proper operation of the oi

system and also minimize the accumulation of

moisture and contaminants between the oi ring

and the viewing window.

12. Connect the keyed connector plug to the 4-pin con-

nector on the IR module.

13. Replace the terminal housing and the sensor hous-

ing. The O-rings must be properly seated to ensure

the water-tight and explosion proof integrity of the

housing. If the unit is equipped with cover locking

clamps, loosen the clamps sufficiently so that the

clamp catches can be seated in the blind holes on

the bulkhead. Fasten the clamps securely using a

5/32 inch hexagonal (Allen) wrench. (See Figure 7.)

14. For best

oi performance, the opening on the oi ring

should be positioned directly opposite the two

oi

test lamps. In addition, the opening should be

pointed down to minimize the accumulation of mois-

ture or contaminants behind the ring.

STARTUP PROCEDURE

When the installation of the equipment is complete, the

following startup procedure should be performed.

1.

Disable any extinguishing equipment that is con-

nected to the system.

2.

Apply input power to the system. Allow an 8 second

power-on delay.

FIRE ALARM PANEL

ALARM

INPUT

EOL DEVICE

**

CENELEC RESISTOR VALUES:

END OF LINE: 5 WATT WITH 2 WATT MINIMUM DISSIPATION

FIRE: 2 WATT WITH 0.7 WATT MAXIMUM DISSIPATION

NO

COM

NC

**

oi

TEST

+

–

+

–

A1293

oi

NO

COM

NC

SPARE

SPARE

F

I

R

E

F

A

U

L

T

U7698B

24 VDC

FAULT

FAULT RELAY SHOWN DE-ENERGIZED

*

*

Figure 8—Typical Wiring Diagram

8