Det-Tronics ATX10 Transmitter SAFETY MANUAL User Manual

Page 4

1.2

95-8658

4

NOTE

Prior to device configuration all alarm outputs

must be bypassed. The device is not safety

certified during configuration change activities.

NOTE

All configuration changes to the FlexSonic

Acoustic Detector (including any changes via

SD card operations) must be verified by the user

via a proof test, power cycle and re-check of

settings, or other appropriate method. The safety

functionality must be validated prior to reliance

on the product for safety protection.

Configuration Protection

Upon completion of installation and commissioning, it

is required that the user password-protect the safety

related parameters that are accessible via HART or

RS485 in order to prevent accidental or deliberate

change of configuration data during normal operation.

To password protect the FlexSonic Acoustic Detector,

the user must set the write-protect function to “on” and

enter an 8 character password. The user should check

the write protect status to ensure that it is set to “on”.

The user will be required to disable write protect prior to

any future configuration changes, and must re-enable

write protect upon completion of these changes to

ensure that HART and RS485 communication remain

non-interfering.

oPERATIoN, MAINTENANCE, INSPECTIoN AND

PRooF TESTING

All normal installation and startup recommendations

as documented in the FlexSonic Acoustic Detector

instruction manual are applicable to the Safety Certified

FlexSonic Acoustic Detector.

Safety-Certified FlexSonic Acoustic Detectors require

proof testing to be performed in all cases.

Personnel performing proof test procedures shall be

competent to perform the task. All proof test results

must be recorded and analyzed. Any corrective actions

taken must be documented in the event that an error is

found in the safety functionality. The proof tests must

be performed prior to commissioning the device and at

least as often as specified in Table 1.

WARNING

Failure to perform the specified testing and

inspection may lower or void the SIL rating for the

product or system.

VISUAL FIELD INSPECTIoN PRooF TEST

Tools Required: None

Visual inspection of all Safety-Certified FlexSonic

Acoustic Detectors shall be conducted as needed

to confirm that no external blockage of the sensor

cover exists, eg. debris, trash, snow, mud, external

equipment, etc. Corrective action shall include

removal of such impediments should they exist. All

acoustic detectors must be inspected to ensure that

they are capable of providing expected performance

and protection.

Completion of Visual Field Inspection Proof Test must

be recorded and documented in the SIS logbook.

RESPoNSE PRooF TEST

Tools

Required: Magnetic tool available from

Det-Tronics, or

HART handheld communicator

The Manual AIC test provides a self check of the

acoustic detector safety function. All acoustic detectors

must be performance tested using the Manual AIC

test procedure and inspected to ensure that they

are capable of providing expected performance and

protection. The Manual AIC test can be initiated and

reset by placing the magnetic tool on the icons on

the ATX10 display, via HART command, or via RS485

command.

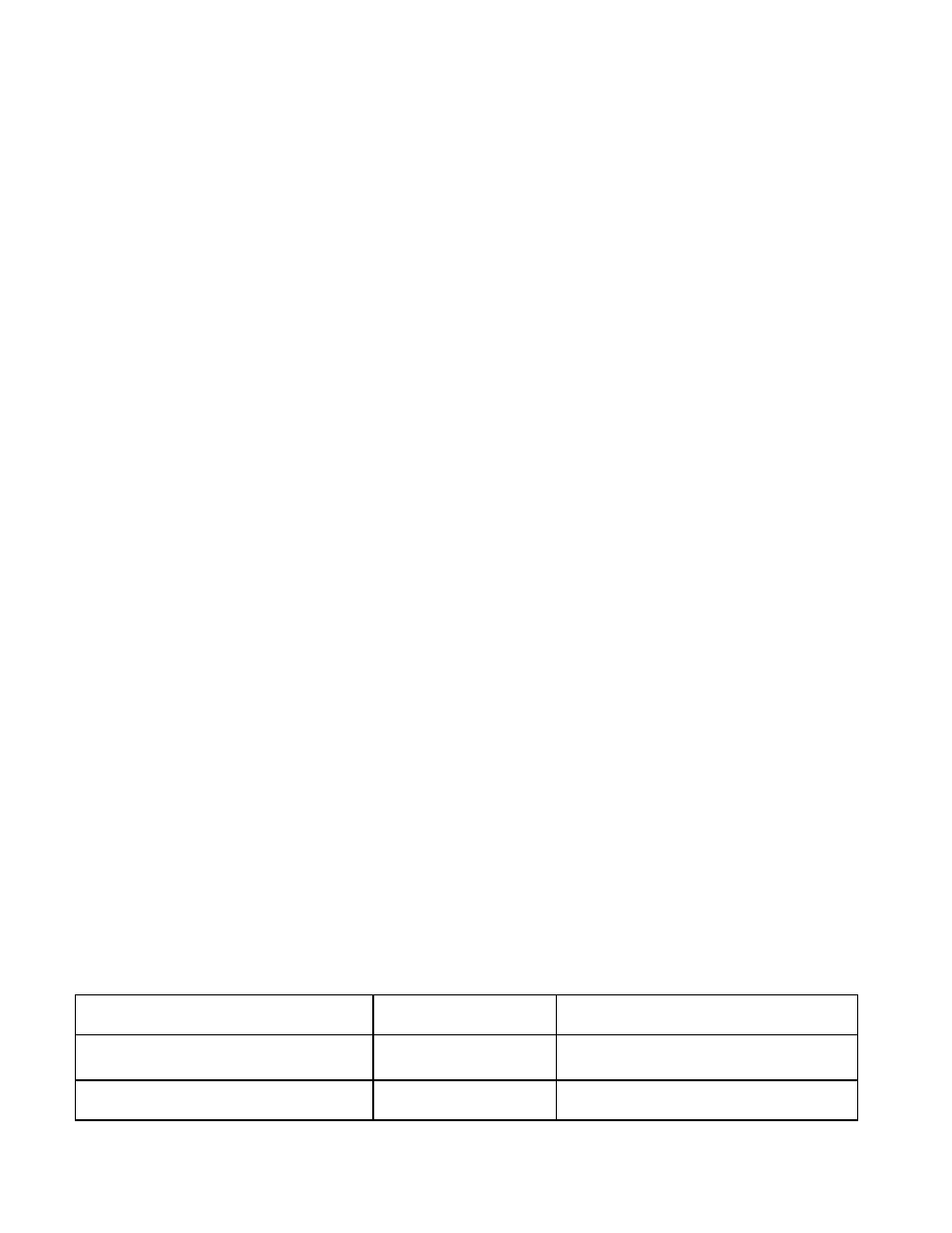

Proof Test Name

Commissioning

Frequency

Visual Field Inspection Proof Test

Yes

As needed, depending on level and type of

contaminants present

Response Proof Test

Yes

1 year

Table 1—Frequency for Performing Proof Tests