Condux Crimp-On Pulling Eyes User Manual

Page 13

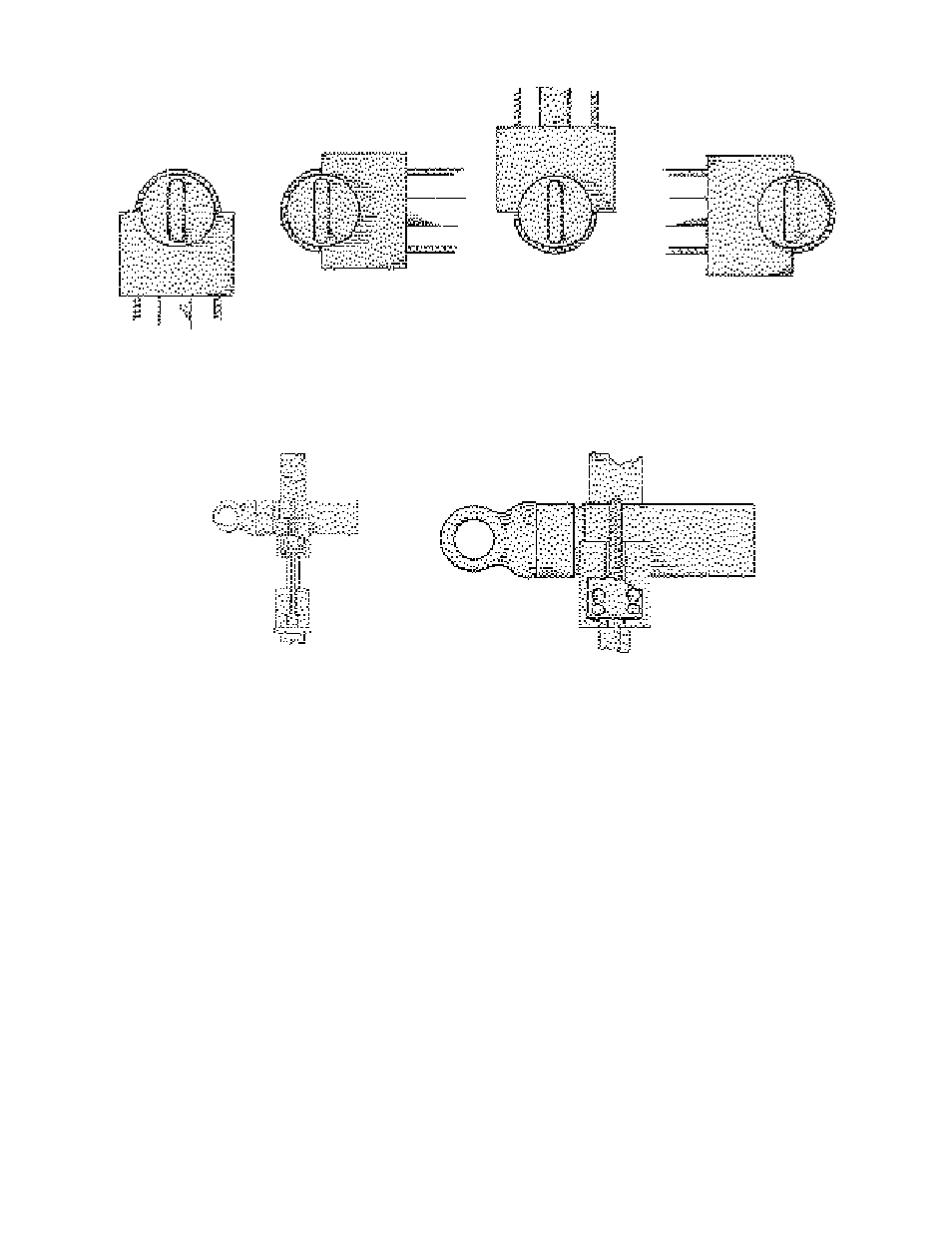

Rotate the crimper assembly 90° on the pulling eye tube. Again extend the ram causing the cable

to crimp the pulling eye tube to a depth of ½ the crimper cable diameter. Do this 4 times on the

first rotation, 360° around the pulling eye. On the second 360° rotation, crimp to the full depth of

the crimper cable diameter. This procedure will require the ram to be extended 8 times per crimp.

Slide the crimper assembly down the pulling eye to make the second crimp. Line up the edge of

the crimper die directly over the center of your first crimp. Repeat the procedure of rotating and

crimping as when making the first crimp.

The 3rd and 4th crimps are made in the same manner: first by locating the crimper die edge over

the last crimp and then the rotating sequence of the crimper assembly.

I. PROCEDURE FOR GEL OR GREASE-FILLED CABLE

When choosing the pulling eye for gel or grease-filled cable, a pulling eye WITH VALVE PORT

must be used. After completing steps A through G, a pulling eye should be installed on a gel or

grease-filled cable using the following procedure:

Remove the pressure port plug from the pulling eye before driving it onto the cable. On the first

crimp, only crimp to approximately one-half the diameter of the crimper cable. Proceed to the sec-

ond and third crimps, again crimping to approximately one-half the diameter of the crimper cable.

On the fourth crimp (third crimp on the 3-Crimp series) crimp to the full diameter of the crimper

cable. Then return to the third crimp and crimp it to full depth, then the second, and finally the

first.

This procedure will expel most of the gel or grease through the pipe

plug port in the pulling eye

head. Replace the pipe plug.

13