Clarus Environmental 4000 Series Automatic Multizone Valve User Manual

Page 4

4

© Copyright 2014. All rights reserved.

4

1

3

6

5

2

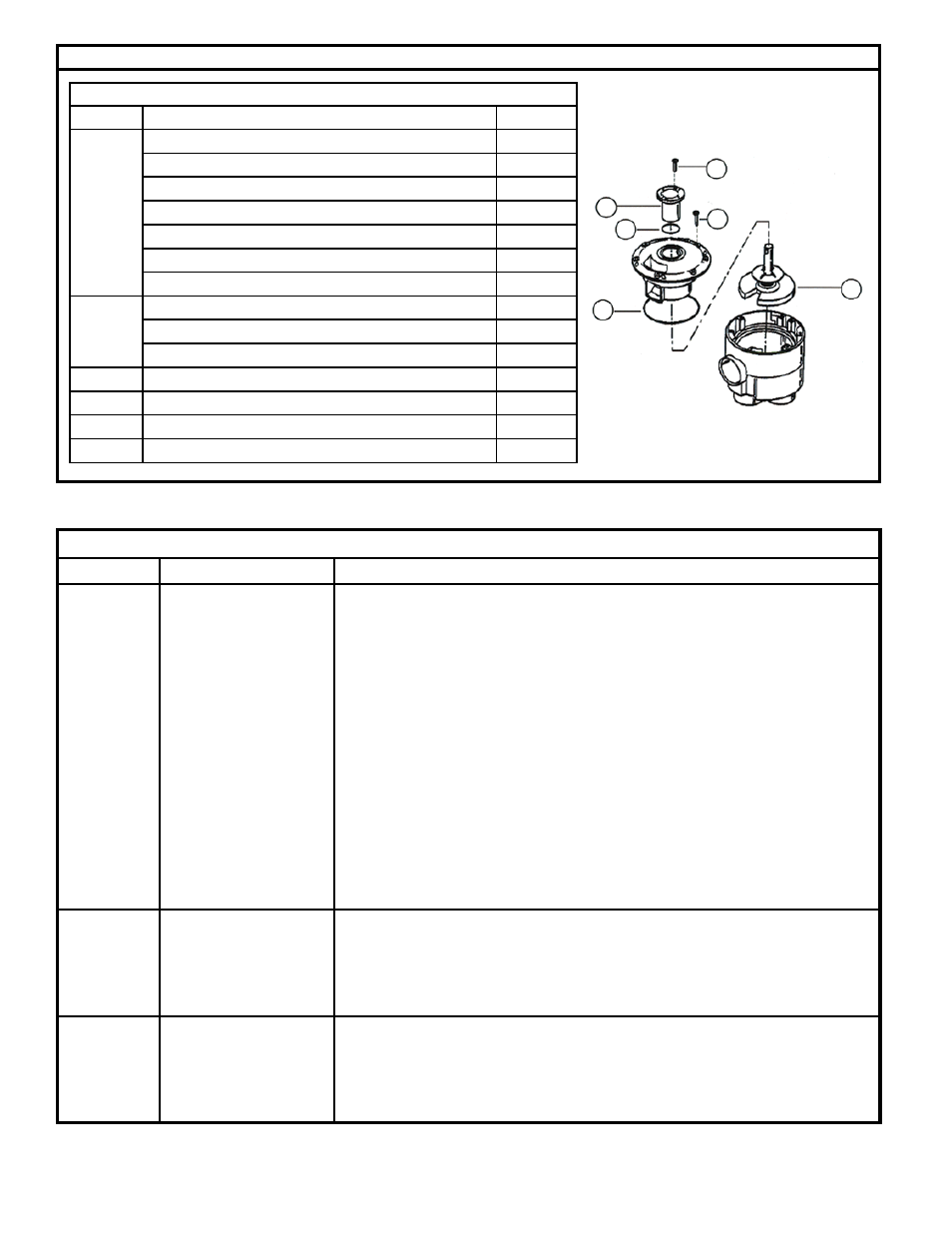

Parts List

REF NO. DESCRIPTION

PART NO.

1

Two zone for four or six outlet valve

153276

Three zone cam for four outlet valve

019586

Four zone cam for four outlet valve

019938

Three zone cam for six outlet valve

153277

Four zone cam for six outlet valve

153278

Five zone cam for six outlet valve

153279

Six zone cam for six outlet valve

152185

2

Stem / disk assy. w/ .028 spring (white)

151236

Light stem / disk assy. w/ .025 spring (blue)

152518

Heavy stem / disk assy. w/ .032 spring (red)

153280

3

Valve top retaining screw set (7)(10x1 Phil Pan SS)

153281

4

Cam retaining screw set (2)(10-24x3/4 Phil Pan SS)

153282

5

Valve Top O-ring

153283

6

Cam O-ring

153284

Parts List

Troubleshooting and Service Checklist

Problem

Cause

Solution

Valve does

not change or

cycle to next

zone or outlet.

The stem and disk as-

sembly is not rotating

when the water flow is

turned OFF and then

back ON.

•

Ensure there is no debris inside the cam. Clean and carefully reinstall the cam.

•

If fewer than the maximum number of outlets are being used, check the

installation of the cam. Ensure that the stem and disk assembly is not being

held down by an improperly installed cam. Refer to the Cam Replacement

Instructions.

•

Remove the valve top and check for proper movement of stem and disk

assembly. Check for and remove any debris or foreign objects that may jam or

retard the movement of the disk.

•

Check for freedom of movement of stem and disk assembly up and down over

the center pin in bottom of valve. Scale deposits may build up on the pin and

hold stem and disk assembly down. Clean pin and again check for freedom of

movement.

•

Be sure that all operating outlets are not capped and that the flow to operating

zones is not restricted in any manner. This would cause pressure to build up in

the valve and lock the stem and disk assembly in the down position.

•

The back flow of water from uphill lines may be preventing the valve from cycling

properly. If the valve cannot be placed close to the high point of the system, a

check valve should be installed near the valve in the outlet line that runs uphill

from the valve.

Water comes

out of all the

valve outlets.

Stem and disk assembly

not seating properly on

valve outlet.

•

Check for sufficient water flow. A minimum of 10 GPM is required to properly seat

the disk. For water flow between 6 and 10 GPM, a stem and disk assembly with a

lighter spring is available.

•

Remove the valve top and check the inside walls to ensure that nothing is

interfering with the up and down movement of the stem and disk assembly inside

the valve.

Valve skips

outlets or

zones.

This will cause the valve

to cycle quickly several

times, skipping one or

more zones. The flow

should be steady and

uninterrupted.

•

The stem and disk assembly is being advanced past the desired outlet.

•

Ensure that the correct cam for the desired number of zones is installed and that

the outlet lines are installed to the correct outlet ports of the valves as indicated

by the zone numbers on the top of the cam.