Clarus Environmental Standard Riser Systems User Manual

Page 2

© Copyright 2012. All rights reserved.

FIG. 5

Pipe Seals

Nominal

Hole Saw

Pipe Size

Diameter

3/8" IPS

1"

1/2" IPS

1-1/4"

3/4" IPS

1-1/4"

1" IPS

1-3/4"

1-1/4" IPS

2"

1-1/2" IPS

2-1/2"

2" IPS

3"

3" IPS

4"

4" IPS

5"

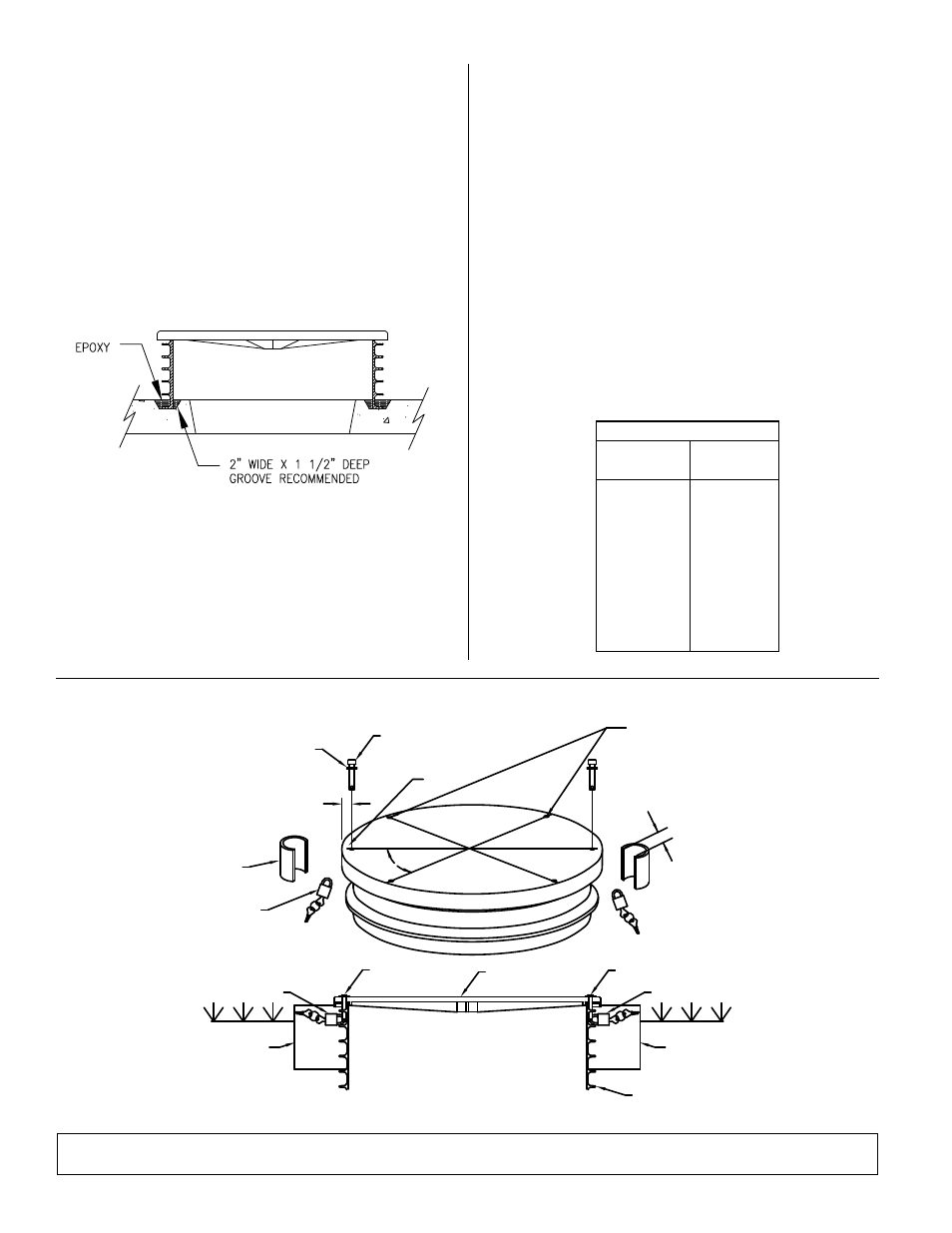

FIG. 4

SK1838

1"

(2 PLACES)

PIN HOLE

PIN

EXISTING LID MOUNTING HOLES

45°

WASHER

LOCK GUARDS (2)

LOCKS (2)

(4" DIA. BY 6"

PIN

LOCK

LOCK GUARD

LID

RISER

BY OTHERS)

(4 PLACES)

(BY OTHERS)

LOCK

LOCK GUARD

PIN

3"

All Clarus Environmental

®

products must be installed and maintained in accordance with all applicable codes.

Product information presented here reflects conditions at time of publication. Consult factory regarding discrepancies or inconsistencies.

FIG. 3

SK2294D

Lockable Latch (See FIG. 4):

Note: Does not apply to 18" dia. riser.

1. Center the lid on the riser and install the mounting

screws.

2. Drill two 7/16” holes 1” from the edge of the lid

approximately 45 degrees from the screws and 180

degrees from each other. The hole should penetrate the

lid and the first rib of the riser.

3. If the lock will be below grade, a 4” pipe or larger,

cut 6” long (furnished by others) with 3” on one side

removed, must be installed next to the riser to allow

access to the padlock. See lock guards in Fig. 4 below.

4. Install the stainless steel pins and washers into the 7/16”

diameter pin holes. Install padlocks (supplied by others)

through the hole in the end of the pins.

Pipe Seals (See FIG. 5):

1. Drill the appropriate size hole in the side of the riser tube.

2. Place the pipe seal in the riser with the largest diameter

inside the riser.

3. To ease pipe installation, lubricate the seal with a mild

soap solution such as dish washing liquid. After the pipe

is installed, clean off any lubricant.

Epoxy Mounting Risers (See FIG. 3):

1. Clean and dry the bottom flange on the riser and the

mounting groove in the septic tank: wash the top of the

tank with detergent and water. Clean the riser with PVC

cleaner or lacquer thinner to provide the best seal.

2. Fill the groove in the tank half way with adhesive (P/N

172-0019). Approximately 1 quart will work for a 24” or

30” diameter riser.

3. Position the riser down in the groove and apply pressure,

submerging the bottom of the riser into to adhesive.

Allow adhesive to dry to a firm, watertight seal.

4. After adhesive has set for 4 hours, backfill with dirt within

24 hours. Be careful not to damage the riser.