Fault log, Configurations, Definitions – Carlin EZ-Temp 90524A User Manual

Page 3

Model 90524A Triple limit or cold-start control — Instructions

Carlin part number MN90524AM Rev. 01/19/09

– 3 –

Where appliance instructions differ from this manual, follow the appliance instructions.

Model 90524A diagnostic LED’s

90524A controls have three LED’s, as explained below. See following pages for operating

sequence and LED behavior.

Left LED

POWER ON

Center LED

CIRCULATOR ON

Right LED

BURNER ON

green

amber

amber

The LED’s can be off, on or flashing. The symbols below are used in this manual to show

the state of these LED’s during operation of the control.

Green LED

OFF

– ON

Power on

FLASH Slowly (once per second) Soft lockout

FLASH Rapidly (twice per second) Hard lockout

Amber LED’s

OFF

– ON

Burner on or Circulators powered

[

Indicates the LED in this position can be either on or off.

LED status

Indicates the following:

Power OFF

With no power applied, the thermostat (TT) circuit and all output con-

tacts are de-energized. All LED’s are off.

Power ON

When power is applied to the L1/L2 terminals, the thermostat circuit is

energized. Voltage (24 VAC) is applied to the thermostat terminals. The

90524A starts a self test to check the sensor and the microprocessor,

and to verify that the limit contacts are open. The 90524A becomes

fully operational after this 2-second self test.

[

Soft lockout

Green LED flashing once per second, burner LED off, B1 contact open,

and circulator LED on or off — occurs if control senses internal failure

or sensor problem (open or shorted sensor).

The control will revert to normal operation if the problem is corrected

within 15 seconds. Otherwise, the control enters hard lockout. See

“Fault log” information below.

Hard lockout

Green LED flashing twice per second, burner LED off and B1 contacts

open, circulator LED on and circulator contacts closed — occurs when

burner contact is sensed closed, and does not clear after two attempts

or soft lockout has timed out.

Reset by cycling power off/on.

Latchup

Green LED off, burner LED off, B1 contact open, circulator LED on, and

ZC and C1 contacts closed — occurs when burner contact is sensed

closed, and does not clear after three attempts.

Not resettable — requires control replacement.

Fault

log

90524A controls self monitor, and can indicate fault conditions with

the LED’s.

Fault conditions are recorded in the retrievable fault log. Two condi-

tions, caused by sensor detection problems, are shown below. Other

LED conditions displayed in the fault log are related to internal control

problems. Reset the control as explained above. Controls in latchup

cannot be reset. They must be replaced.

To access the fault log, press the hidden reset button (located left of

the LOW LIMIT adjustment on the front of the control). Hold for one

second or longer. All three LED’s will come on for 1 second, then go off

for 1 second. If any error codes have been logged since the last error

code display, the LED’s will flash a pattern four times for each error

code, then proceed to the next. After all codes have been shown, the

error code log will automatically clear.

For applications that might encounter unexplainable control outages,

contact Carlin Technical Support for instructions to access the fault log

and interpret the results.

Sensor open

Sensor OPEN fault code.

The sensor is detected OPEN (resistance more than 60 Kohms).

Sensor shorted

Sensor SHORTED fault code.

The sensor is detected SHORTED (resistance less than 300 ohms).

Configurations

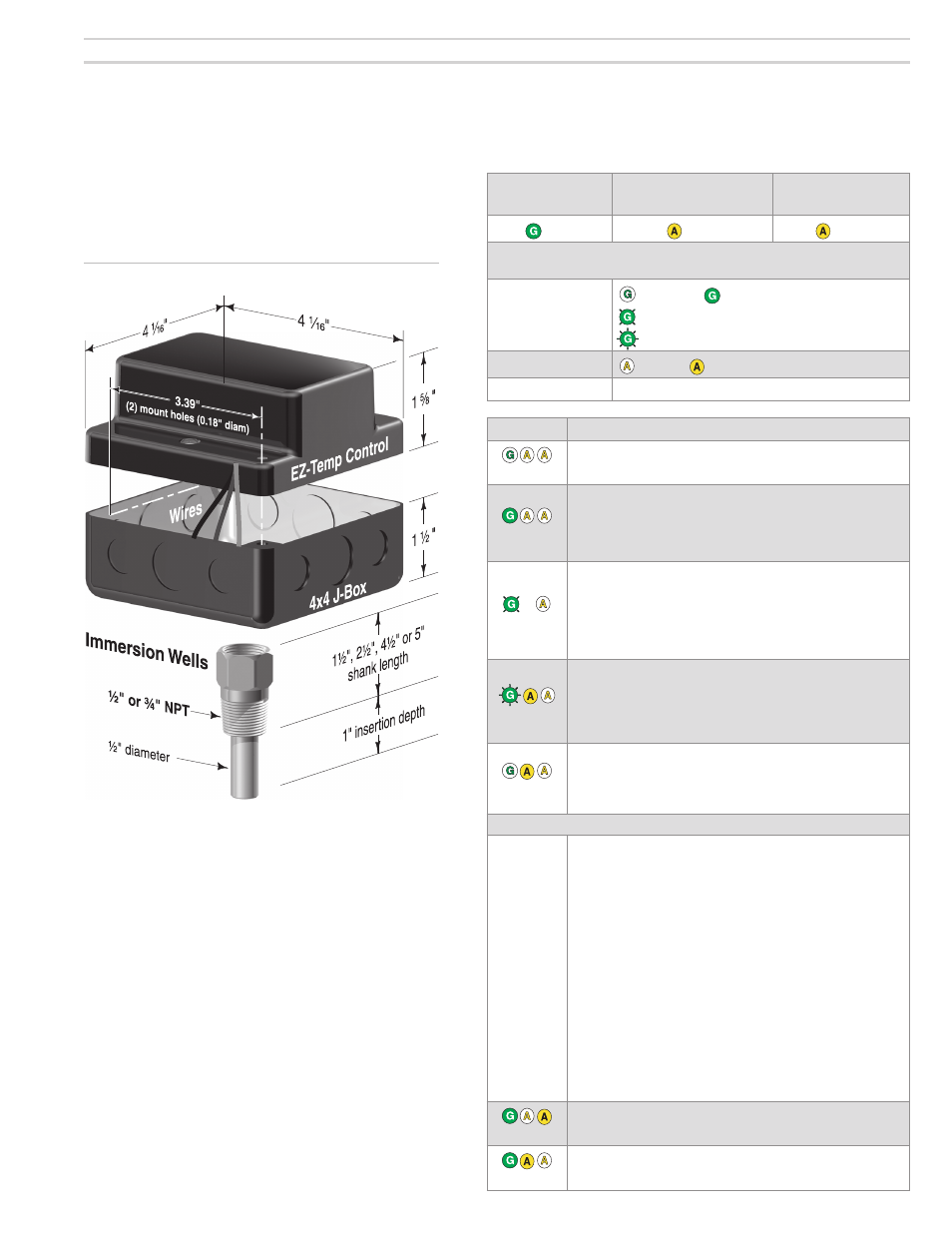

Control kits — 90524A controls mount to a standard 4x4 J-box, supplied

•

with the control. Mount the box directly to a well (new or existing) with

hardware supplied, or panel mount. See Figure 2 for dimensions.

Well kits — Wells for 90524A sensors are available in the sizes shown

•

in Figure 2. Well kits include sensor mounting hardware designed to

hold sensor securely in position.

Sensors — Sensors are available in single configurations.

•

Mounting the 90524A

Figure 2

Definitions

High limit

Shut-off temperature during space heating (call for heat at

T-T or ZR).

Setpoint is adjustable at lower front center of control.

•

Differential is fixed when in triple limit operation (LOW

•

LIMIT on).

Differential is adjustable on back of control when in cold

•

start operation (LOW LIMIT set to OFF).

Low limit

Temperature maintained during stand-by (no call for heat

at T-T or ZR) when in triple limit operation (LOW LIMIT on).

The setpoint for the low limit (minimum temperature in

•

the boiler during standby) is adjustable with the lower

left adjustment.

The differential for low limit is adjustable with the adjust-

•

ment on the back of the control.

The circulator output at C1 is activated only when

•

the temperature in the boiler is above the low limit

setting.

Low temp

Boiler condensation protection setting when in cold-start

operation (LOW LIMIT set to OFF).

This setting is fixed.

•

The differential is fixed.

•

The circulator outputs are disabled until the boiler tem-

•

perature rises above the low temp setting.