Prepare site • prepare burner • mount burner, Prepare burner and components, Model 201gas burner — instruction manual – Carlin 201GAS User Manual

Page 7

Model 201GAS burner — Instruction manual

Carlin part number MN201GAS Rev. 03/14/11

– 7 –

Where appliance instructions differ from this manual, follow the appliance instructions.

1. Prepare site • prepare burner • mount burner

(continued)

Prepare burner and components

Do not install or operate the burner if any component is damaged

or if burner does not comply with the specifications of Table 1

and other guidelines in this manual.

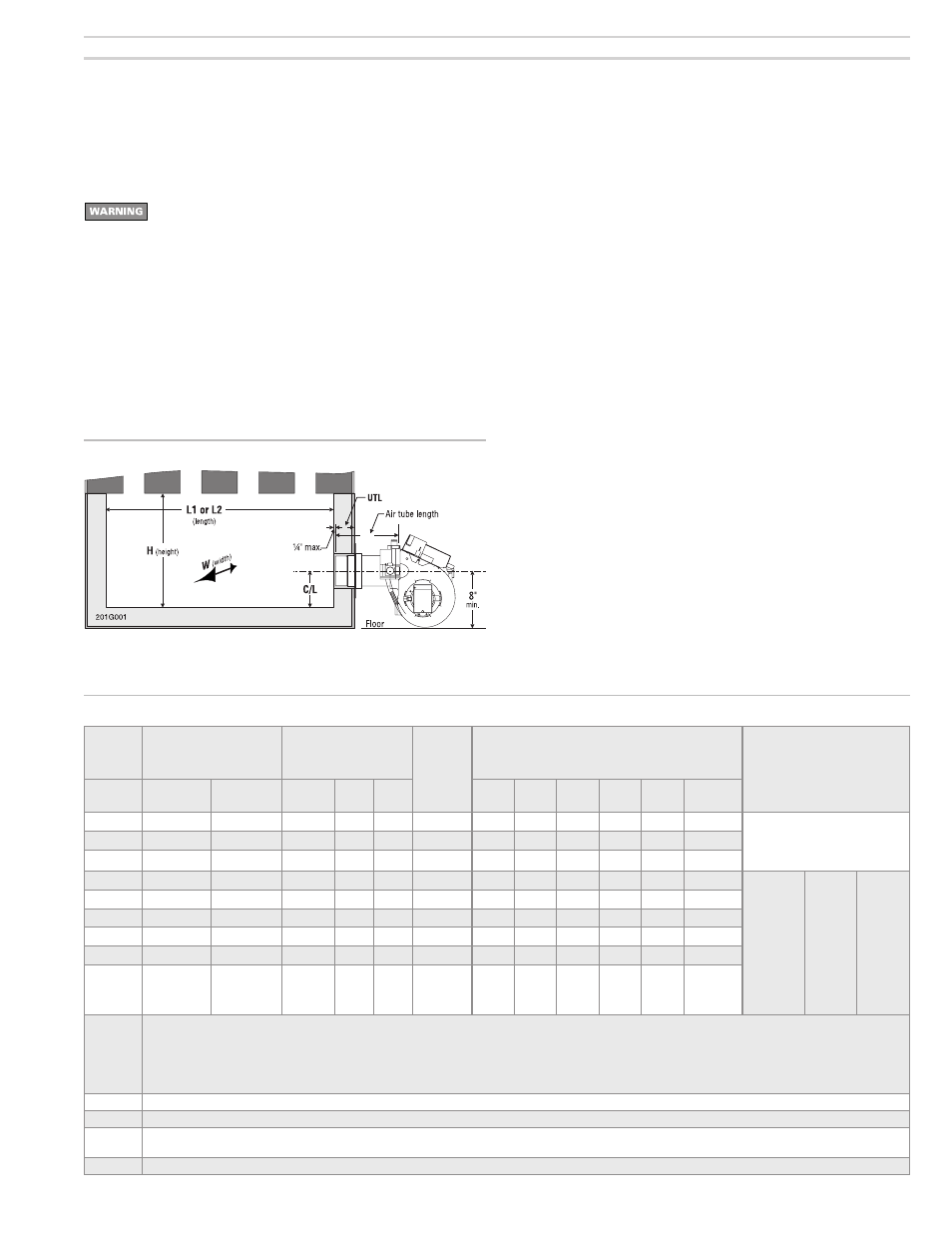

Air tube insertion length (UTL)

• Usable air tube length (UTL) is the distance from mounting flange to end

of air tube. Verify that the end of the air tube will be flush with, or no more

than ¼ inch short of, the inside of the appliance combustion chamber

front wall when the burner is mounted. See Figure 3 and Table 1 below,

for further information.

Diffuser plate

• Verify correct diffuser plate (item 2, page 3). Compare diffuser plate listed

on air tube label with diffuser plate listed in Table 1.

Figure 3 Combustion chamber dimensions (see Table 1)

Gas orifice drill size

• The gas orifice is drilled through a plate in the end of the orifice nipple

(see item 8, page 3). Read the factory-drilled orifice size on the label

attached to the burner air tube (see item 1, page 3) near the blower

housing end. If the gas orifice size is not correct for your application,

or if the label is illegible for any reason, check the orifice size directly

and redrill orifice or replace if necesary, as follows (next page).

Table 1 Burner specifications for 201GAS burners

Input

Note 1

Burner orifice

drill size

Approximate

air band setting

Notes 1 & 2

Diffuser

Minimum chamber dimensions

Inches (Notes 3, 4, 5)

(VC = min. diam. of vertical cylinder chamber)

UTL

Air tube

insertion length

Btuh

Natural

gas

Propane

gas

%

Slots

Air

shutter

C/L

L1

L2

W

H

VC

150,000

9/32

7/32

15

2

Yes

C

4

11

14

8

10

9½

Burners with welded flange have fixed

usable tube length (UTL). Verify length

is correct for the application. Burners

with adjustable flange: Usable tube

length (UTL) varies with air tube length:

175,000

5/16

1/4

30

2

Yes

C

4

12

16

8

10

10

200,000

11/32

9/32

60

2

Yes

C

4½

14

17

8

11

12

225,000

11/32

9/32

8

2

No

B

4½

15

18

9

11

13

Nominal

air tube

length

----------

8”

10”

12”

14”

16”

UTL

min.

---------

1 ¾”

1 ¾”

1 ¾”

1 ¾”

1 ¾”

UTL

max.

---------

2 ½”

4 ½”

6 ½”

8 ½”

10 ½”

250,000

3/8

5/16

25

2

No

B

4½

16

19

9

11

14

275,000

13/32

5/16

40

2

No

B

4½

17

21

10

11

15

300,000

13/32

5/16

15

4

No

A

5

17

21

12

12

15

350,000

15/32

11/32

35

4

No

A

5½

17

21

12

12

15

399,000

9/16

7/16

80

4

No

A

6

20

24

14

13

17

Note 1

High altitude applications: The maximum burner input at sea level is 399,000 Btuh. Reduce this capacity by 4% per 1,000 feet above sea level. Example — max.

capacity at 5,000 feet is 319,000 Btuh (20% reduction).

Pressurized firing: Maximum burner input decreases with increasing overfire pressure. Assume a reduction in maximum burner input of approximately 5% at 0.1

inches w.c. and 10% at 0.2 inches w.c. You will have to increase the air band opening to compensate for the increased pressure. Follow the procedures given in

this manual to check combustion with instruments to determine the correct air band setting. Do not fire into a chamber with pressure higher than 0.2 inches w.c.

and never fire at a higher pressure than recommended by the appliance manufacturer.

Note 2

Use this as the starting setting only. Adjust air band setting, if necessary, after performing combustion testing (see page 13).

Note 3

Some tested appliances may operate satisfactorily with dimensions less than the above.

Note 4

Horizontal cylindrical chambers — diameter must be no less than column “W” above

Horizontal stainless steel cylindrical chambers — diameter at least 1 to 4 inches larger than column “W” above.

Note 5

A corbel may help heat transfer in a larger boiler or furnace, provided it is recommended by the appliance manufacturer.