Operation – Carbolite CAF 16/38 User Manual

Page 6

CAF16

6

MF45 – 1.05

3.0 O

PERATION

The instructions for operating the temperature controller are given in a separate manual.

If the furnace is fitted with a time switch, see also the supplementary manual MS03.

3.1 Basic Furnace Operation

The furnace is fitted with an instrument switch. The switch cuts off power to the control circuit.

Connect the furnace to the electrical supply.

Operate the instrument switch to activate the temperature controller. The controller becomes

illuminated and goes through a short test cycle. Adjust the temperature controller (see controller

manual).

Overtemperature option only. If the overtemperature controller has not yet been set as required, set

it and activate it according to the instructions in the appropriate manual.

Unless a time switch is fitted and is off, the furnace starts to heat up. The Heat light(s) glow

steadily at first and then flash as the furnace approaches the desired temperature or a program

setpoint.

Unless a time switch is fitted and is off, the furnace starts to heat up. The Heat light(s) glow

steadily at first and then flash as the furnace approaches the desired temperature or a program

setpoint.

Overtemperature option only. If the overtemperature trip operates then an indicator in the

overtemperature controller flashes, and the heating elements are isolated. Find and correct the

cause before resetting the overtemperature controller according the instructions supplied.

To turn the furnace off, set the Instrument switch to it’s off position; the controller display will go

blank. If the furnace is to be left off unattended, isolate it the electrical supply.

3.2 Setting up for Coal Ash Fusion Test

The CAF 16/38 is designed to be compatible with the following:

BS 1016 : Part 113 : 1995 ISO 540 : 1995 Methods for Analysis and Testing of Coal and Coke.

Part 113. Determination of Ash Fusibility.

The test procedure is entirely manual and under user control. An example of the procedure is as

follows.

Heat the furnace up to its starting temperature.

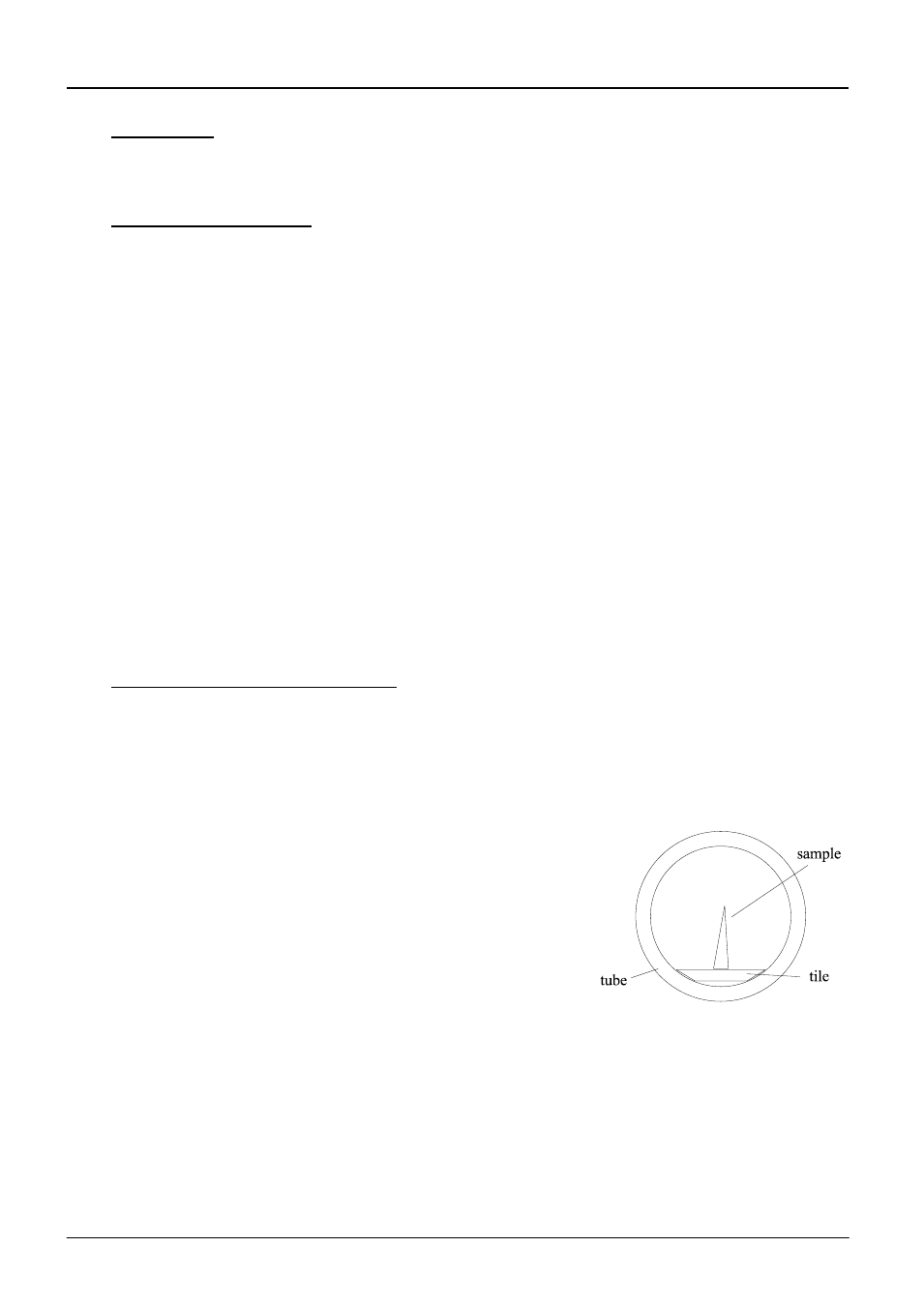

Open the furnace door and swing it clear of the work tube to

allow access. Load the sample into the work tube. The sample

tile with one or two samples on it should be placed centrally

along the length of the work tube.

Set the ramp rate on the controller, if required, to limit the

heating rate. A rate of 7

C/min is suggested and is factory

preset.

Set the controller to heat the furnace up to the final temperature. Swing the telescope into place to

allow observation of the sample.

Watch the sample and record the temperature at which it fuses. Make all other records such as time

and temperature as required by your own organisation.

Switch off and allow to cool down; or set the setpoint to zero or to the normal test starting

temperature, so that the temperature is displayed as the furnace cools.