C.B.S. Scientific TTGEK-2401-220 User Manual

Page 36

36

www.cbsscientific.com

3.6 Gel Casting Techniques.

A. Gel Wrap™ Gasket Casting Method.

B. Vertical gradient gel casting using GM-40 gradient maker and gravity flow.

C. Vertical gradient gel casting using GM-40 gradient maker and a Mini-pump.

D. Vertical gradient gel casting using GM-40 gradient maker, Mini-pump and Multi-gel Caster.

A. Gel Casting using Gel Wrap Gasket Casting method

For Vertical DGGE, TTGE or SSCP, use the set of spacers which do not have the small hole or

channel milled into the lower end, these are for casting perpendicular gels.

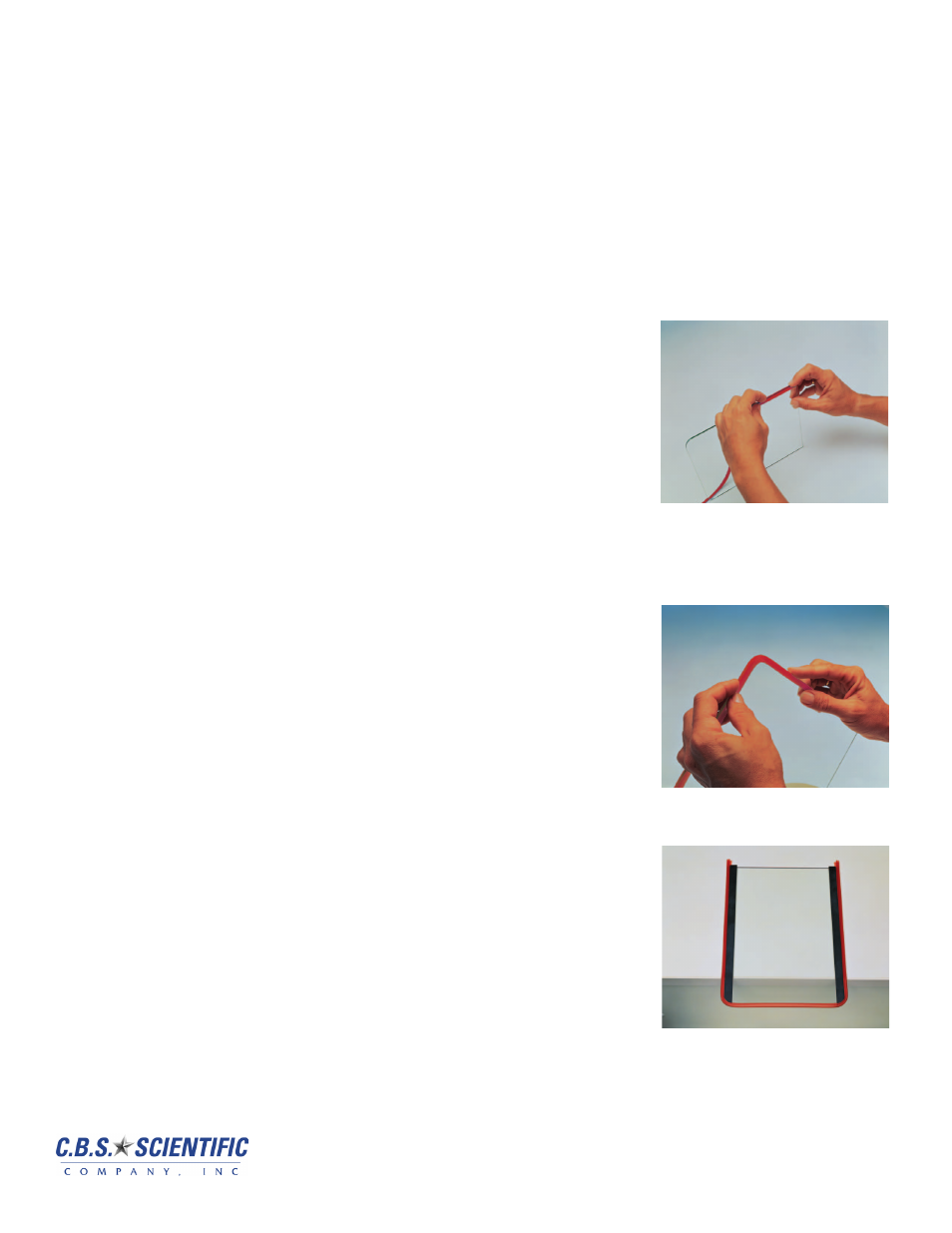

1. Start by holding the rectangular back plate with the rounded bottom

corners and start applying the gasket around one side of the glass

plate. NOTE: one side of the “U” shaped gasket is flat and the other

side has tubing that will act as a seal around the spacers.

2. When applying the gasket over the rounded corners of the back

glass plate,make sure the notches on the gasket align with the

rounded corners of the glass plate. Once the gasket is pushed over

the bottom edge and corners, work it down the remaining side.

3. Place the gasketed plate on the lab bench with the tubing side up,

and extend the bottom of the plate over the edge of the bench,

approximately ¾ of an inch. Place the spacers along side the inside

edges of the gasket. Be sure the rounded corner end of each spacer

is facing the outside bottom of the plate, following the radius of the

glass.