Troubleshooting analysis – Autoquip FREIGHTLIFT FLHC User Manual

Page 96

96

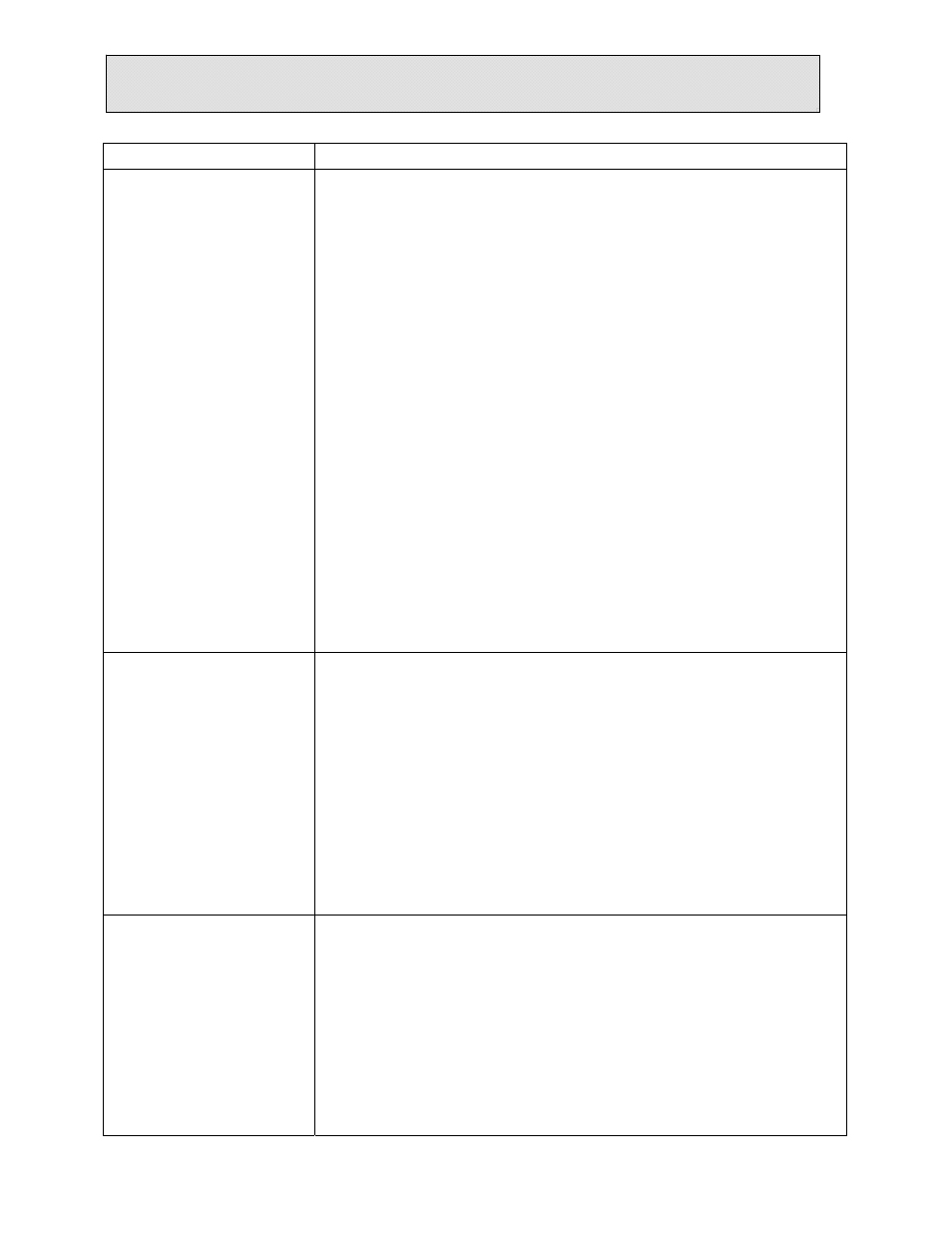

PROBLEM

POSSIBLE CAUSE AND SOLUTION

The Freightlift will not

lower (electrically).

WARNING! a safety

device may have been

activated – if you are

not familiar with how

safety devices interact

with the operation of

the lift, you must find

someone who does.

Or, call Autoquip

Customer Service at

888-811-9876.

The emergency stop button may be depressed or jammed.

Check all pushbutton stations. Repair as necessary.

The main disconnect switch / distribution panel circuit

breaker is tripped or a fuse is blown. Check and reset or

replace as necessary.

A door with status switch is open, or switch or interlock is

malfunctioning or is out of tolerance. Close door, or check

and repair or adjust as required.

The push button / circuit is malfunctioning. Check

components and circuit. Repair or replace.

The motor starter overloads (MSO) have tripped. Check

and reset. If it trips again, check for cause in the motor

circuit.

The control transformer fuse is blown. Check and replace.

Check for tripped velocity fuses.

A - air in the system will cause a lockup

B - heavy oil will cause a lockup.

C - Cold temperatures of -10 F or lower will

cause a lockup.

NOTE: CONTACT THE AUTOQUIP SERVICE

DEPARTMENT BEFORE ATTEMPTING TO REPAIR THIS

PROBLEM!!

Motor labors or heats

excessively.

The voltage may be low. Check at the motor terminals

while the pump is running under load. Do not check at the

line source or while the pump is idling. Inadequate wiring

can starve the motor even when the source voltage is

ample.

The wiring may be incorrect. Be sure one leg of the motor

line is not connected to the ground prong. This can happen

particularly on 3-phase units using twist-lock plugs.

The pump may be binding from oil starvation. This can

cause high internal heat. The pump can be irreparably

damaged by oil starvation and may have to be replaced!

The Freightlift does not

raise completely to the

upper level

(press “emergency

stop” button to stop

motor.)

The carriage stops at the upper level are not adjusted

correctly

The oil level in the reservoir may be too low. Check and

replace. Determine the cause of the oil condition and

repair.

There is some sort of interference with the platform

carriage. Check and correct.

The load exceeds the capacity of the unit. Lower the unit,

unload, and try again.

TROUBLESHOOTING ANALYSIS