Troubleshooting analysis – Autoquip FREIGHTLIFT FLT User Manual

Page 72

72

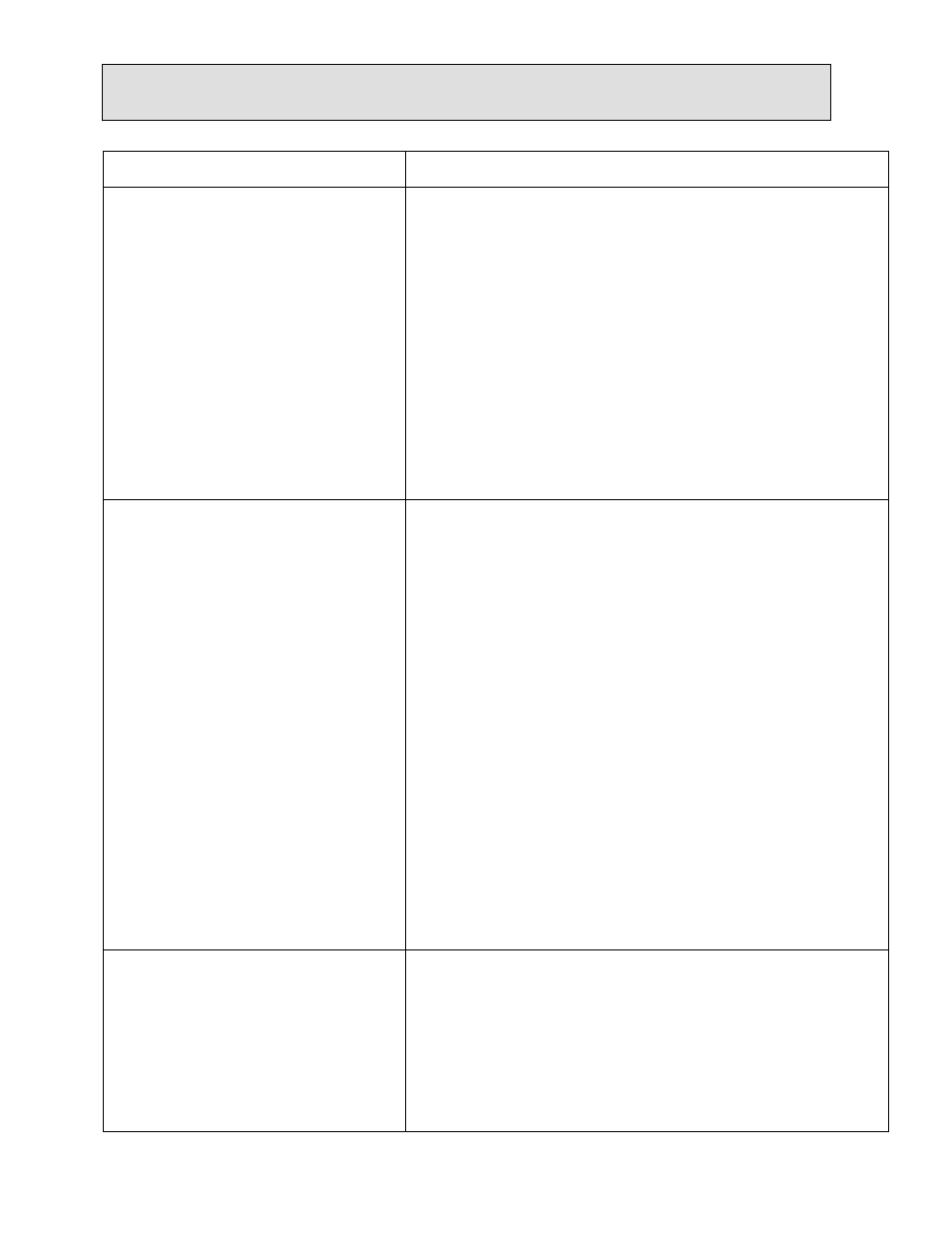

PROBLEM

POSSIBLE CAUSE AND SOLUTION

Motor labors or heats excessively.

• The voltage may be low. Check at the motor

terminals while the pump is running under load.

Do not check at the line source or while the pump

is idling. Inadequate wiring can starve the motor

even when the source voltage is ample.

• The wiring may be incorrect. Be sure one leg of

the motor line is not connected to the ground

prong. This can happen particularly on 3-phase

units using twist-lock plugs.

• The pump may be binding from oil starvation.

This can cause high internal heat. The pump can

be irreparably damaged by oil starvation and may

have to be replaced.

Unit operates in a “spongy” or

jerky fashion.

• The load may exceed the stated capacity of the

unit. Overloading caused the pressure switch

valve to activate and deactivate if the “UP” button

is depressed. The motor may start and stop if

this condition exists. Remove excess load.

• The hydraulic system may have air in it. The unit

requires bleeding (see Air Bleeding Procedures

in the Routine Maintenance section).

• Check for oil starvation.

• The rollers may be binding. Check and repair.

• The platform carriage may be binding in the

guideways. Check and repair.

• The cylinder may be binding internally or

externally. Check and repair.

• The pressure switch may be turning the motor on

and off. Check and repair.

Motor will not turn off when lift

reaches fully raised position

• Relief valve setting is too low and oil is flowing

over relief. Need to adjust setting upward per

instructions in Installation section.

• Pressure switch setting is too high and oil is

flowing over relief. Need to adjust downward per

instructions in Installation section.

TROUBLESHOOTING ANALYSIS