Warning – Autoquip SERIES 35 SCISSORS LIFT User Manual

Page 19

19

6. Temporarily connect electrical service and hydraulic hoses. The hose connection on the end of the

base frame is 1/2" female NPT.

Hydraulic Piping/Hose Size

Up to 25 feet

½” ID

26 feet to 50 feet

¾” ID

Over 50 feet

1” ID

7. Check the routing of the temporary hydraulic lines to

assure that the hose is clear of legs, base frame, and

platform when lift is in the lowered position.

8. Fill hydraulic reservoir with proper type and volume of fluid.

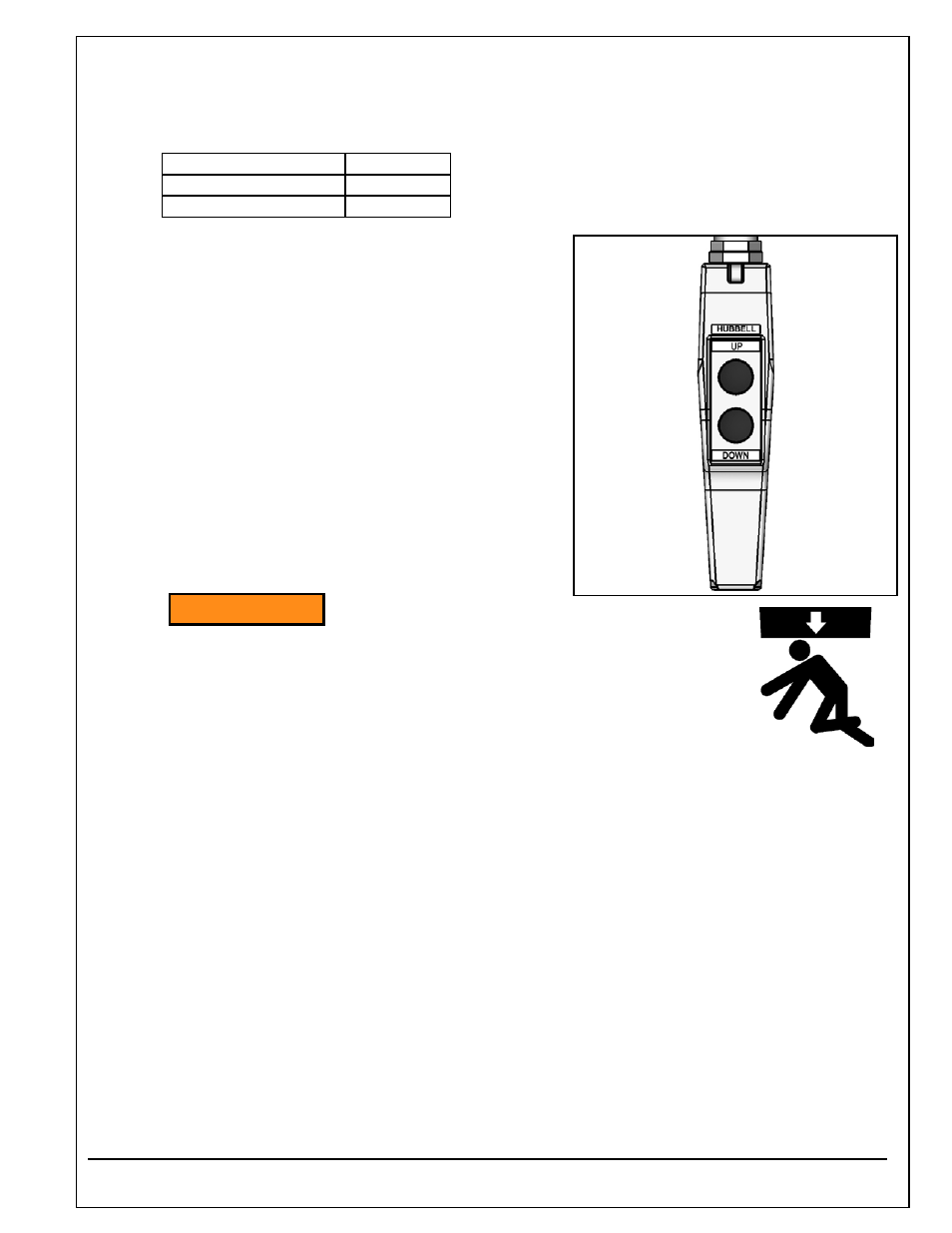

9. Press “UP button and raise lift one foot.

10. Press “DOWN” button to fully lower lift. Continue to hold

down button for 60 seconds. Repeat procedure five to

seven times to bleed air out of hydraulic system.

11. Raise and lower lift as needed to make positioning

adjustments.

12. Adjust platform to a clearance of 1” minimum around

perimeter between platform and pit angle.

NEVER go under a raised lift platform until load is removed and

lift is securely blocked in raised position with maintenance

devices.

See "Maintenance Device" section of this manual.

Lock-out/tag-out power source.

13. Base frame of lift has pre-drilled holes for anchoring to the floor. Anchor lift to floor. Lifts with oversize

platforms have minimum pull out requirements of 2,000 lbs. for each anchor. See “Shimming And

Anchoring Lift To Concrete”.

14. Make permanent electrical and hydraulic connections and operate lift through a few cycles.

15. Clean up debris and spilled oil from area. Dispose of oil in an environmentally safe manner.

16. Touch-up paint is available from Autoquip for repair of damaged paint surfaces.

17. Train personnel on lift operation, all safety features and procedures.

^ WARNING