Installation, Operation – AMMCO 6950 Twin Cutter Tool User Manual

Page 2

2 • 6950 Twin Cutter Tool

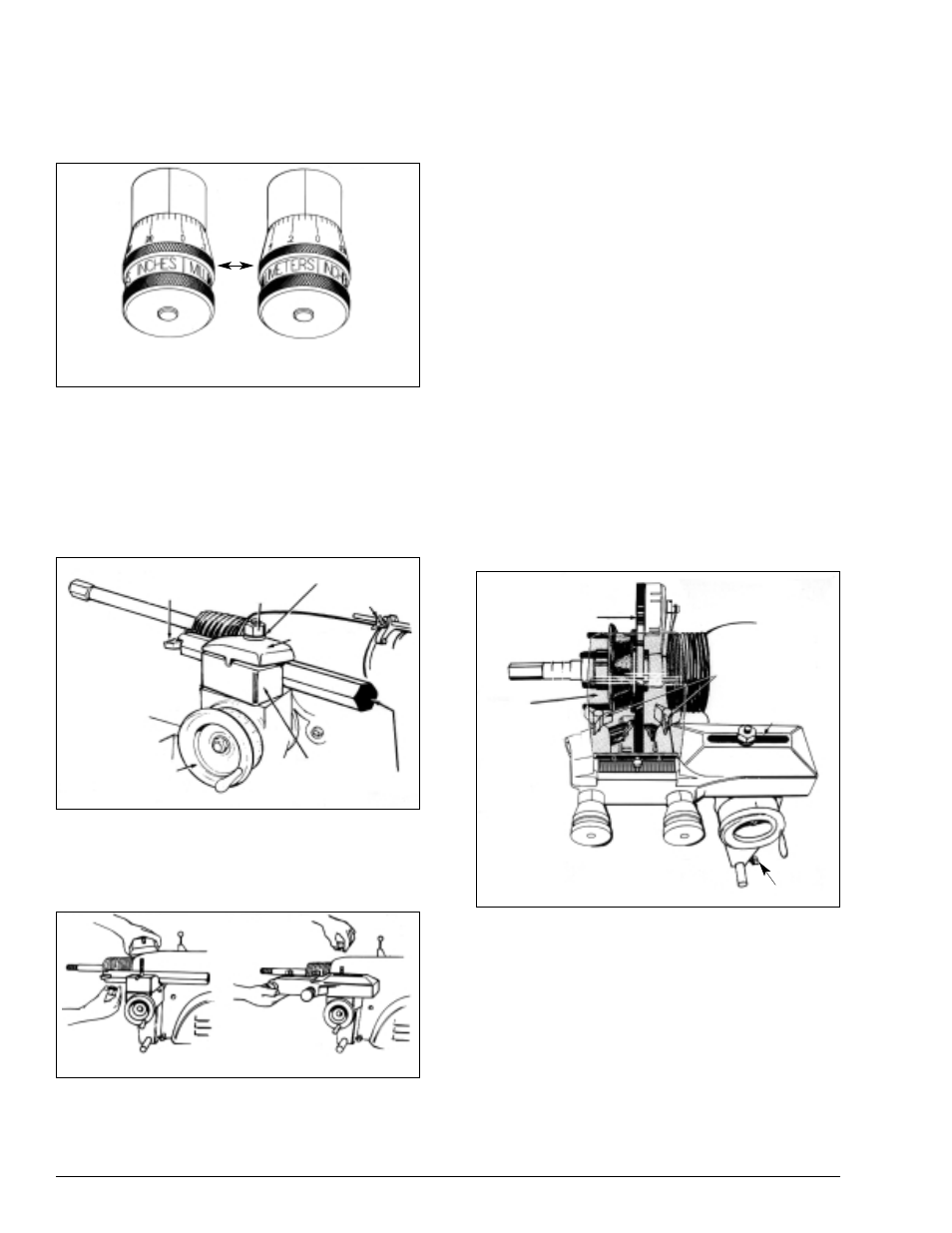

The 6950 Twin Cutter Tool mounts on the lathe in

place of the boring bar. It resurfaces both faces of

a brake rotor simultaneously. Each tool holder is

individually adjustable (in thousandths of an inch

or millimeters) to facilitate precise depth-of-cut

settings (Figure 1).

Figure 1 – Depth-of-cut adjustment knobs

Installation

1.

Remove the nut and self-aligning washers

from the boring bar mount on the lathe.

2.

Lift off the upper and lower clamp and

remove the boring bar (on models 4000 and

4100 only). Only the stud remains.

Figure 2 – Lathe set up for drum turning

3.

Place the twin cutter on the stud.

4.

Place the self-aligning washers on the stud,

followed by the nut. Hand tighten the nut.

Figure 3 – Remove boring bar and install twin cutter

5.

Visually align the slot in the top of the twin

cutter so it is parallel to the lathe arbor.

Operation

A brake rotor is machined from its center

outward, cutting both faces at the same time.

1.

Measure the rotor thickness with a

micrometer and determine the depth of cut

necessary to machine both surfaces.

2.

Determine the minimum allowable thickness

(cast into the rotor, or from manufacturers

specifications) and do not machine down past

this minimum.

NOTE: When machining single piston or

floating caliper rotors, more metal may be

taken off one face than the other provided the

minimum overall thickness specification is

maintained.

3.

Loosen the cross slide lock and turn the

crossfeed handwheel to back the twin cutter

out far enough to clear a mounted rotor.

4.

Mount the rotor on the lathe arbor using the

appropriate adapters.

NOTE: The mounted rotor illustrated in Figure

4 is a non-vented type. Both vented and non-

vented rotors up to 1.75" (44.5 mm) thick may

be resurfaced with the 6950 twin cutter.

Figure 4 – Lathe set up for rotor turning

5.

Center the rotor between the tool bits by

positioning the twin cutter to the left or right

along the cast slot (or by adjusting the spindle

feed handwheel).

6.

Install a rotor silencer to dampen machining

vibrations.

7.

Set the lathe V-belt to the correct groove for

optimum speed and finish. Refer to the lathe

operations manual for proper speeds and

feeds. Generally, slow speeds give a better

finish and longer life.

Dial set to cut 4/1000

of an inch(0.004")

Dial set to cut 1/10

mm (0.1 mm)

Micrometer

Inner

Sleeve

Tool Bit Holder

Nut

Self-Aligning Washers

Crossfeed

Handwheel

Upper Clamp

Lower Clamp

Spindle Lock

Boring Bar

Remove Clamps and Bar

Install Twin Cutter

Rotor

Tool Holder

Lock Knobs

Slot Centers Twin

Cutter to Rotor

Cross Slide

Lock Knob

Safety Shield

Must Be Used