Data sheet, Ace backstage co., inc, Stage pocket systems – ACE BACKSTAGE Super Stage Pocket User Manual

Page 6

ACE BACK

STAGE CO., IN

C.

CLEAR C

OM

DMX12

PUSH

PUSH

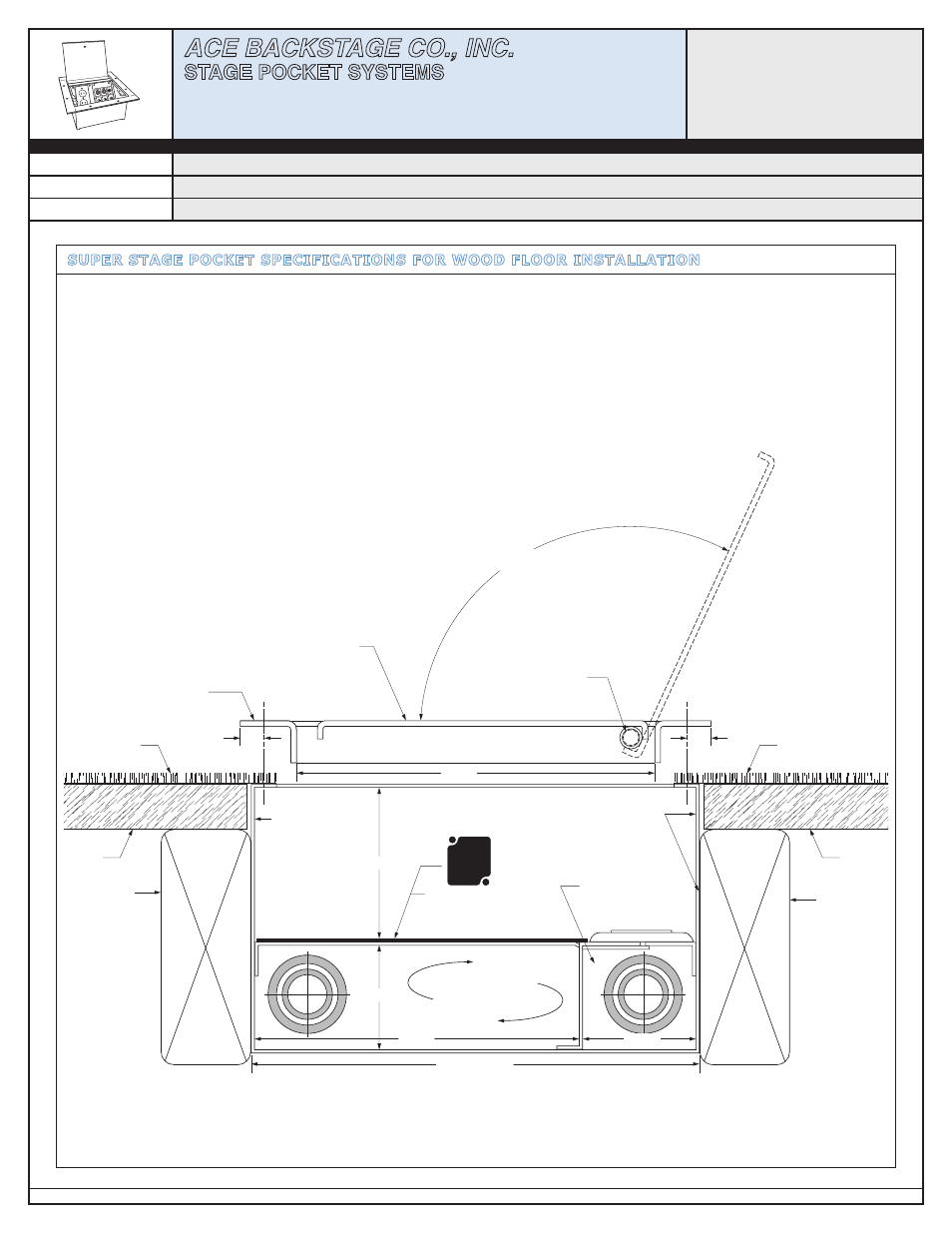

SUPER STAGE POCKET SPECIFICATIONS FOR WOOD FLOOR INSTALLATION

3.375"

2.335"

7.250"

8.000"

2.530"

10.000"

SQUARE

TRIM BEZEL

MOUNTING

FLANGE &

LID ASSEMBL Y

NOMINAL

OPENING

REMOVABLE SPRING LOADED

HINGE PINS PERMIT EASY LID

EXCHANGE FOR CARPET, LOCKING,

AND STANDARD LID CONFIGURA

TIONS

CARPET

FLOOR

LEVEL

WOOD

FLOOR

"CONNECTRIX" PANEL

SYSTEM

COMBINATION OF "#PNL-100",

"#PNL-120", OR "#PNL-140"

STAGE POCKET

PANELS

BARRIER ISOLA

TED

LOW VOL TAG E SECTION

CREATED WHEN #BRK102

BRACKET KIT ASSEMBLY

IS INSTALLED

BARRIER ISOLA

TED

AC SECTION CREA

TED

WHEN #BRK102 BRACKET

KIT ASSEMBLY

IS INSTALLED

SUPER STAGE POCKET

BACK BOX #BRK102BBX

SET THE SUPER ST

AGE POCKET

BACK BOX #BRK102BBX SECURELY

BRACED INTO T

HE FLOOR TO PROVIDE

SUPPORT EQUAL T

O THE FLOOR

LOADING REQUIREMENTS, ACCOUNTING

FOR ANY HEIGHT OFFSET REQUIRED

FOR THE FINISHED FLOOR

WOOD

FLOOR

FRAMING

CARPET

FLOOR

LEVEL

LID (BLIND HINGE), SPRING LOADED PINS,

AVA ILABLE IN STANDARD FLUSH , STANDARD

FLUSH LOCKING, OR RECESSED CARPET

WOOD

FLOOR

FRAMING

WOOD

FLOOR

.500"

.500"

Ace Backstage Co., Inc. Stage Pocket Systems | 24846 Avenue Rockefeller | Suite 200 | Valencia, CA 91355 | Tel: 661-295-5760 | Fax: 661-295-1122 | Web: www.acebackstage.com

6 of 6

ACE BACKSTAGE CO., INC.

STAGE POCKET SYSTEMS

24846 Avenue Rockefeller | Suite 200 | Valencia, CA 91355

Tel: 661-295-5760 | Fax: 661-295-1122

Email: [email protected] | Web: www.acebackstage.com

DATA SHEET

Stage Pocket

Data Spec Sheet

Revision: 1A.132-232

Model Numbers:

#132-xxyy, #232-xxyy (xx= Lid Type and yy= Finish Type)

Model Name:

Super Stage Pocket - Super Capacity Horizontal Panel Pocket

Model Description: Pocket with brushed metal or powder coat finish, choice of lid, with optional panel(s) and connectors

1) - Locate box and install conduit in accordance with local codes

2) - Secure box to wood floor framing, floor joist or otherwise to assure the box is fixed below the finished floor

3) - Provide support for the box equal to the floor loading requirements

4) - Account for any height offset required for the finished floor

5) - Install wire and other devices as required using standard electrical conduit

6) - After box and conduit are secured, complete the connector/panel installation

7) - Install trim bezel/lid hinge assembly to secured box with screws provided