4 chipping – Echo 72928 Owners Manual v.2 User Manual

Page 15

12

S

E C T I O N

2

to full speed.

9. If the chipper jams, reverse the feed by moving the

control arm in the reverse direction. Remove the

branch and rotate it before reinserting it into the chute.

Alternately insert and retract the limb or insert

continuously at a rate that will not kill the engine.

Chipping dead, dry material will create heat and

dull the chipping blades quickly. Alternate greener

material with dry material to lubricate the chipping

blades for longer life and better performance. When

the chipping blades become dull, they will require

periodic sharpening. Refer to Service and Mainte-

nance, "Sharpening Chipper Blades."

Stopping Instructions:

1. Move throttle to slowest position.

2. Depress foot clutch pedal.

3. Turn key switch to off position.

4. Allow machine to come to a complete stop. Release

the foot clutch pedal to help slow the rotor once the

engine has stopped running.

NOTE: The heavy rotor will continue to turn for some

time after the engine. You can tell that the rotor has

stopped when no noise or machine vibration is present.

WARNING: Do not leave machine unattended, or

attempt any inspection or service unless the engine is

stopped and the key is removed from key switch.

2.4 Chipping

The Bear Cat chipper is designed to chip a variety of

materials into a more readily decomposing or handled

condition. The following guidelines can be used to help

you get started.

Please read and follow all safety instructions in

this manual. Failure to operate the chipper in

accordance with the safety instructions MAY RESULT

IN PERSONAL INJURY!

1. Be sure the unit is at full operating speed before you

start to chip material.

2. Select limbs that are up to 9 inches in diameter.

Trim side branches that cannot be bent enough to

feed into the chipper chute. Small diameter

branches can be held together in a bundle and fed in

simultaneously.

3. Feed brush from the side of the infeed chute, rather

than from the front. Then, step aside to avoid being

hit by the brush moving into the chipper.

4. Never lean over the infeed chute to push objects

into the cutting device. Use a push stick or brush

paddle.

5. Never use shovels or forks to push brush. They can

go through the chipper, are expensive to replace and

cause major damage. In addition, metal pieces can

come back like shrapnel to injure or kill.

6. Never push brush into the infeed chute with your

feet.

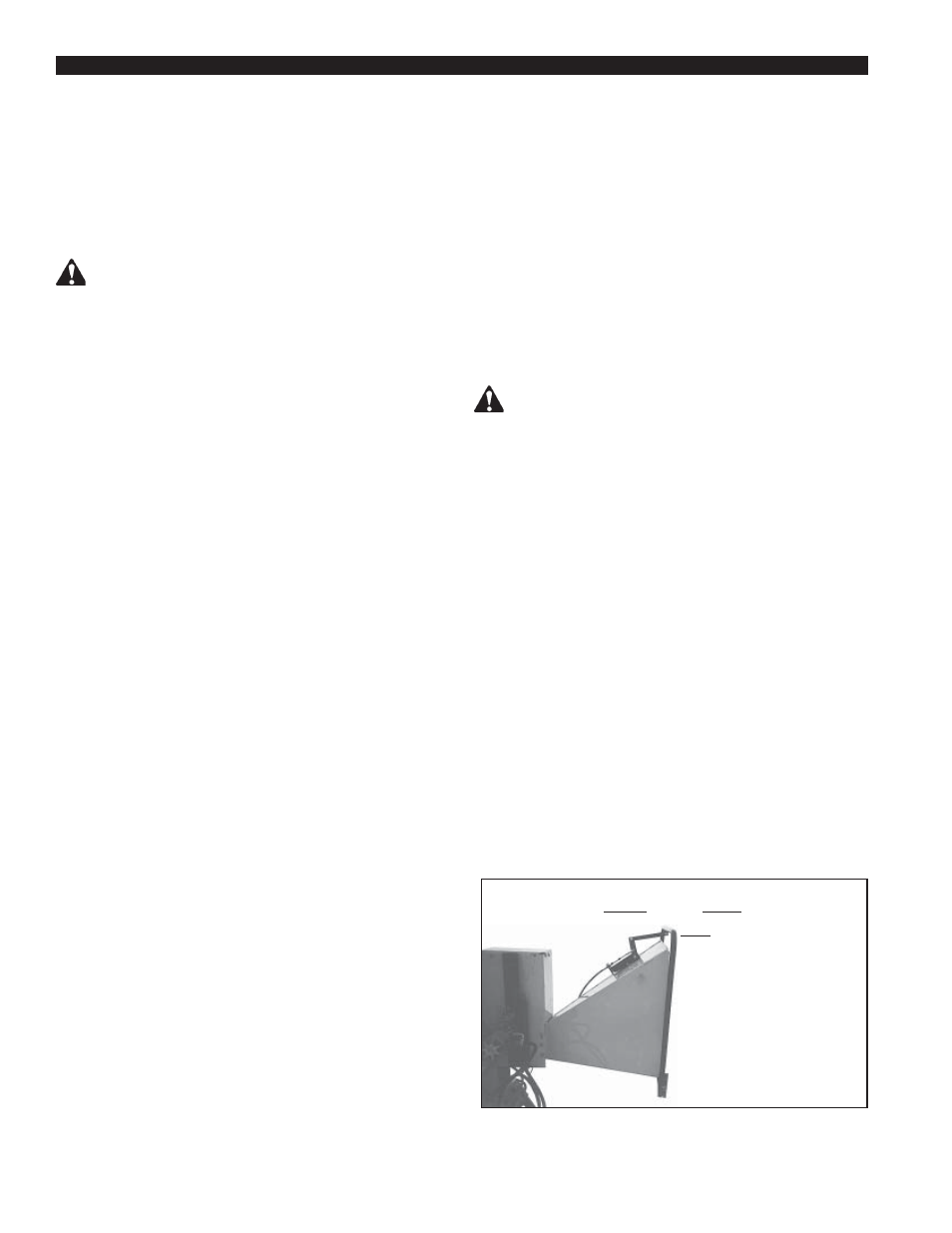

7. Engage the hydraulic feed by moving the control

arm. Pull the arm toward you to engage the hydrau-

lic feed (see figure 2.9). In the forward direction,

the feed rate increases as the arm is moved.

8. Place limb, butt end first, into the chipper chute

until it contacts the hydraulic feed roller and is

drawn into the chipper blades. The actual feed rate

of the limb into the chipper will depend on the type

of material fed, and sharpness of the cutting blades.

If the engine slows to where it may stall, push the

control lever inwards to slow or stop the material

feeding and allow the engine to recover. Pull the

lever out to restart feeding when the engine is back

Feed Control

Lever

▲▲▲▲▲

Forward

▲▲▲▲▲

Reverse

Neutral

Figure 2.9