Warning, 9 greaseable bearings and pivots – Echo 74824 Owners Manual v.3 User Manual

Page 20

Page 18

6" & 8" Bear Cat Chipper Operator’s Manual

NOTE

Polyuria and lithium based greases are not compatible.

Mixing the two grease types may lead to premature failure

of the chipper.

NOTE

The use of pneumatic grease equipment is not

recommended unless low pressure is assured.

5.9 GREASEABLE BEARINGS AND

PIVOTS

SERVICE & MAINTENANCE

10. Install the four 1/2 inch bolts on each bearing to secure

them to the frame. Tighten bolts to 75 Ft-lb.

11. Slide rotor assembly forward to remove any existing

play in the assembly. Relocate the bushing and rotor

sheave to remove the play in the rotor assembly.

12. Replace drive belt on pulleys and depress the foot clutch

pedal. Check alignment of pulleys and adjust engine

sheave if needed. Release foot clutch pedal.

13. Check belt tension before start-up (see Section 5.5).

14. On hydraulic feed units, replace the hydraulic belt and

tighten the bolts that anchor the hydraulic pump to

mount.

15. Close rotor access cover and replace bolts.

16. Replace belt guard and resume operation.

17. Depress foot clutch pedal, start engine, release foot

clutch pedal to engage belt, and test unit. Readjust

pulleys and belt tension if needed.

It is extremely important to slide the rotor assembly for-

ward to remove any existing play in the rotor assembly.

Failure to do so could result in the chipper blades strik-

ing the chipping anvil. This could result in serious injury

or death.

WARNING

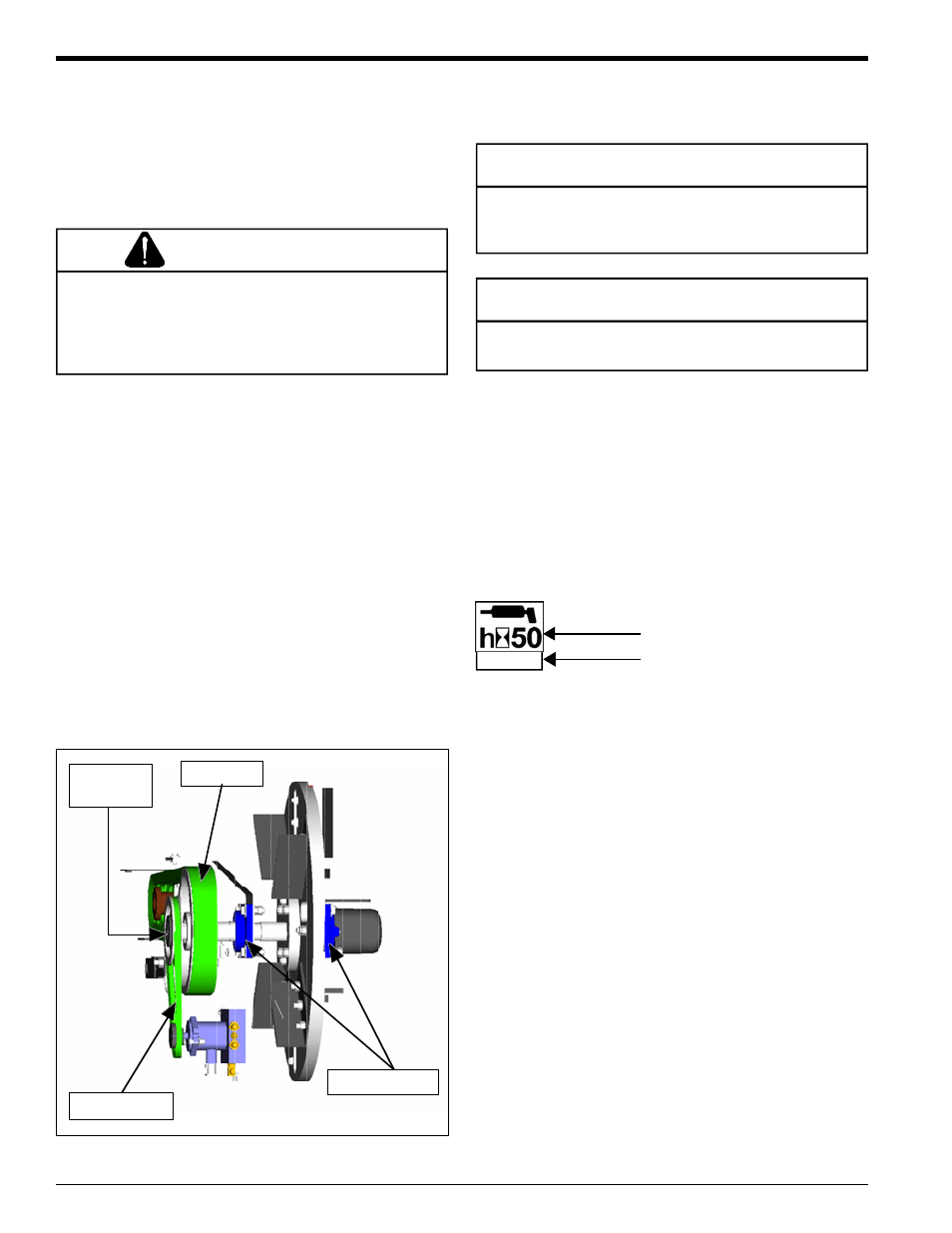

Figure 5.5- Rotor Bearings

Bushing &

Pulley

Drive Belt

Hydraulic Belt

Rotor Bearings

Mounted bearings are pre-lubricated at our factory and are

ready for operation.

RELUBRICATION:

Relubrication of bearings is determined by operating

conditions and environment. Relubricate standard bearings

with a LITHIUM based grease. Greasing intervals and

quantities are shown on the next page using the following

symbol:

GREASING INTERVALS:

Bearings in extreme environments will require more frequent

greasing intervals.

GREASE FILL AMOUNTS:

It is preferred that experience dictate fill amounts due to

wide variances in applications, greasing equipment and

operating conditions. The quantities shown on the next page

are recommended amounts. In most cases, it is best to

relube in small amounts, under low pressure, until a thin

bead of fresh grease is visible at the seal lip area.

Care should be taken when greasing bearings to avoid

overfilling. Overfilling can lead to excessive heat and/or

unseating of the seals. Grease should be introduced in small

amounts and under light pressure. Whenever possible, the

bearing should be rotated slowly while grease is added to

ensure equal distribution throughout the raceways.

The chipper models described in this manual have eight (8)

greaseable bearings and pivots that require greasing. Refer

to the Figures 5.6 through 5.11 on the next page for greasing

intervals and quantities.

Quantity

Recommended

quantity of grease.

Frequency (i.e. 50 hours).