Warning, 7 clearing a plugged rotor, 8 repairing or replacing ro- tor bearings – Echo 74824 Owners Manual v.3 User Manual

Page 19: 6 adjusting drive belts

Page 17

6" & 8" Bear Cat Chipper Operator’s Manual

5.7 CLEARING A PLUGGED ROTOR

Feeding too large or too much chipable material at once

may plug the chipper. To clear a plugged rotor, proceed as

follows:

1.

Depress foot clutch pedal and turn off engine key switch.

Release foot clutch pedal when engine is stopped.

2.

Remove the two 3/8" retaining bolts holding the access

cover to the main frame assembly.

WARNING

If the machine becomes plugged, depress the foot clutch

pedal, shut off the engine, disconnect the spark plug wire

and allow the machine to come to a complete stop before

clearing debris. Do not operate the machine without proper

guards and shields in place.

5.8 REPAIRING OR REPLACING RO-

TOR BEARINGS

1.

Remove the two 3/8 inch retaining bolts holding the ac-

cess cover to the main frame assembly. Tilt access

cover over to allow access to rotor.

2.

Remove large belt guard (three 5/16 inch bolts).

3.

On hydraulic feed units, loosen bolts that anchor the

hydraulic pump to mount and remove hydraulic belts.

4.

Step down on foot clutch pedal to release tension and

remove drive belt from pulleys.

5.

Using the push bolts from the bushing, remove the bush-

ing and pulley from the rotor shaft.

6.

If a rotor bearing needs repair, it is best to remove the

complete rotor assembly from the chipper frame.

7.

Using an overhead hoist or lifting device, remove the

four 1/2 inch bolts on each rotor bearing and lift the rotor

assembly completely out of the frame. The complete

rotor assembly weighs 275 lbs.

8.

Once the rotor assembly is out of the frame, both bear-

ings on the rotor assembly shaft can be removed by a

puller and replaced.

9.

Use the overhead hoist or a lifting device to return the

complete rotor assembly to the chipper frame.

SERVICE & MAINTENANCE

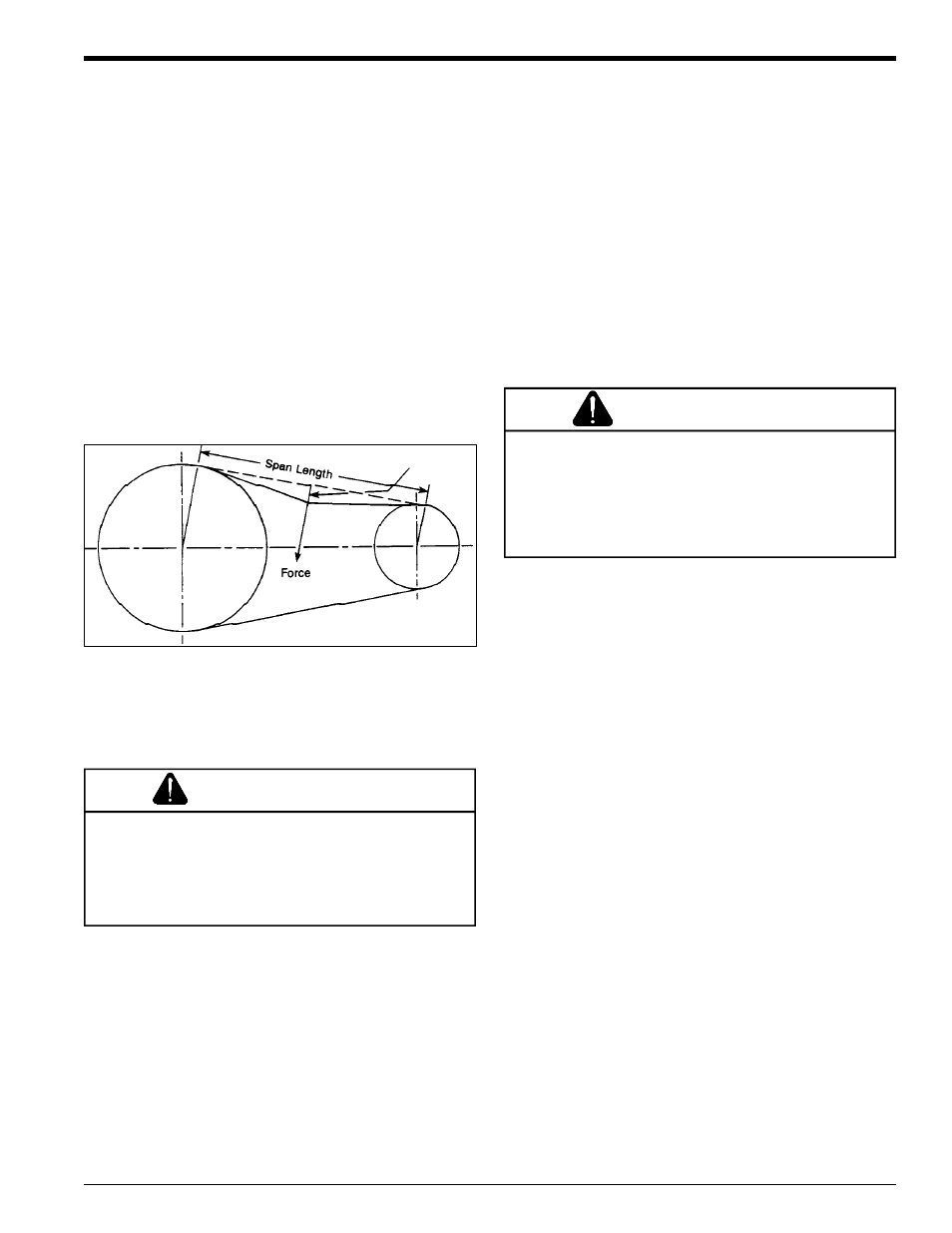

5.6 ADJUSTING DRIVE BELTS

1.

Depress foot clutch pedal. Shut engine off and discon-

nect battery cables.

2.

Remove large belt guard (three 5/16 inch bolts).

3.

Adjust the eyebolt that anchors the idler spring to ad-

just belt tension. Tighten the eyebolt until the belt de-

flection at the center of the belt is 7/16" when a 20 lb.

load is placed against the belt (see Figure 5.4).

4.

Replace belt guard.

5.

Start engine, release foot clutch pedal to engage belt,

and test unit. Readjust pulleys and belt tension if needed.

To adjust the drive belt tension, proceed as follows:

Figure 5.4 - Drive Belt Tension

3.

Lift up rotor access cover.

4.

Clean the debris out the chipper rotor. Turn the rotor by

hand to be sure it is free to rotate. Be careful to avoid

the chipper blades when cleaning out the debris.

5.

Close rotor access cover and replace bolts.

6.

Depress foot clutch pedal, and start the engine. Re-

lease the foot clutch pedal when engine is running to

engage drive belt. Resume operation.

WARNING

The rotor assembly has a lock mechanism (see Figure

5.1). When working on the rotor assembly, use the lock

mechanism at all times. There is a hole in the rotor jack

shaft and a matching hole in the bracket mounted to the

rotor bearing front side. Install a punch through the rotor

shaft and bracket to lock the rotor in place.

Refer to Figure 5.5 while repairing or replacing rotor bearings.

7/16" Deflection