Service & maintenance 5, Warning – Echo 74824 Owners Manual v.3 User Manual

Page 17

Page 15

6" & 8" Bear Cat Chipper Operator’s Manual

5.2 SHARPENING CHIPPER BLADES

When the chipper blades dull, chipping becomes difficult. It

is recommended that the chipper blades are sharpened every

5-15 hours of chipper operation.

Use the following procedure to remove the chipping blades

for sharpening:

1.

Remove the two 3/8 inch retaining bolts holding the ac-

cess cover to the main frame assembly.

2.

Tilt access cover over to allow access to rotor. Rotate

the rotor so that the bolts holding the chipper blades

are most accessible.

3.

Install the rotor (disk) lock (see Section 5.1). The disk

is now restrained for removing the blades. To access

the remaining blades, remove the punch or screwdriver

and reposition disk. Return the punch or screwdriver to

the rotor lock hole.

4.

Remove the two hex head bolts holding the blade to the

rotor.

NOTE

The chipper blades consist of two edges (see Figure 5.2).

When the first edge dulls, flip the blade and torque to 75

Ft-lb to use the second sharp edge. Repeat this procedure

for each blade. After both edges are dull, sharpen the

chipper blades.

WARNING

Before inspecting or servicing any part of the machine,

shut off the power source, disconnect the spark plug wire

from the spark plug and make sure all moving parts have

come to a complete stop. The chipping blades are sharp!

Use care when working on machine to avoid injury.

S e c t i o n

Service & Maintenance

5

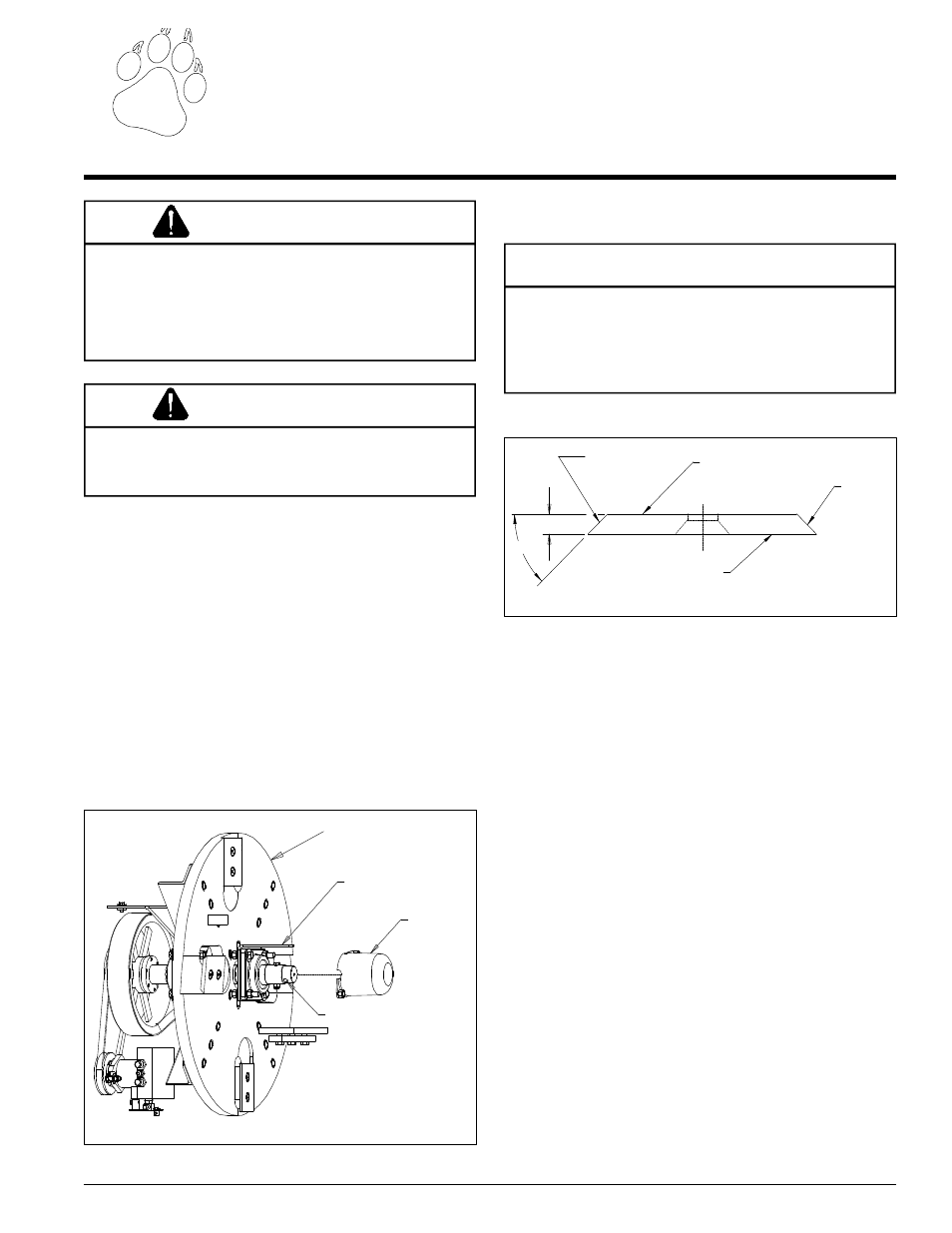

5.1 INSTALLING THE ROTOR (DISK)

LOCK

When working on the rotor (disk) assembly, use the lock

mechanism at all times (see Figure 5.1). Follow the steps

below to install the rotor lock:

1.

Remove the plastic rotor shaft cover under the chipper

chute. There is a hole in the rotor jack shaft and a match-

ing hole in the bracket mounted to the rotor bearing

frontside.

2.

Install a punch or screwdriver into the rotor shaft and

bracket to lock the rotor in place.

WARNING

The rotor (disk) assembly has a lock mechanism. When

working on the rotor assembly, use the lock mechanism

at all times.

Figure 5.2 - Chipper Blade Surfaces

45°

.38

MOUNTING SURFACE

DO NOT GRIND

MOUNTING SURFACE

DO NOT GRIND

SHARPENED

SURFACE

SHARPENED

SURFACE

Figure 5.1 - Rotor (Disk) Lock

ROTOR LOCK HOLE.

ROTOR SHAFT CAP

MATCHING HOLE IN BRACKET

ROTOR (DISK) ASSEMBLY