4 setting chipper blade clearance, 5 replacing drive belts, 3 replacing chipper blades – Echo 74824 Owners Manual v.3 User Manual

Page 18

Page 16

6" & 8" Bear Cat Chipper Operator’s Manual

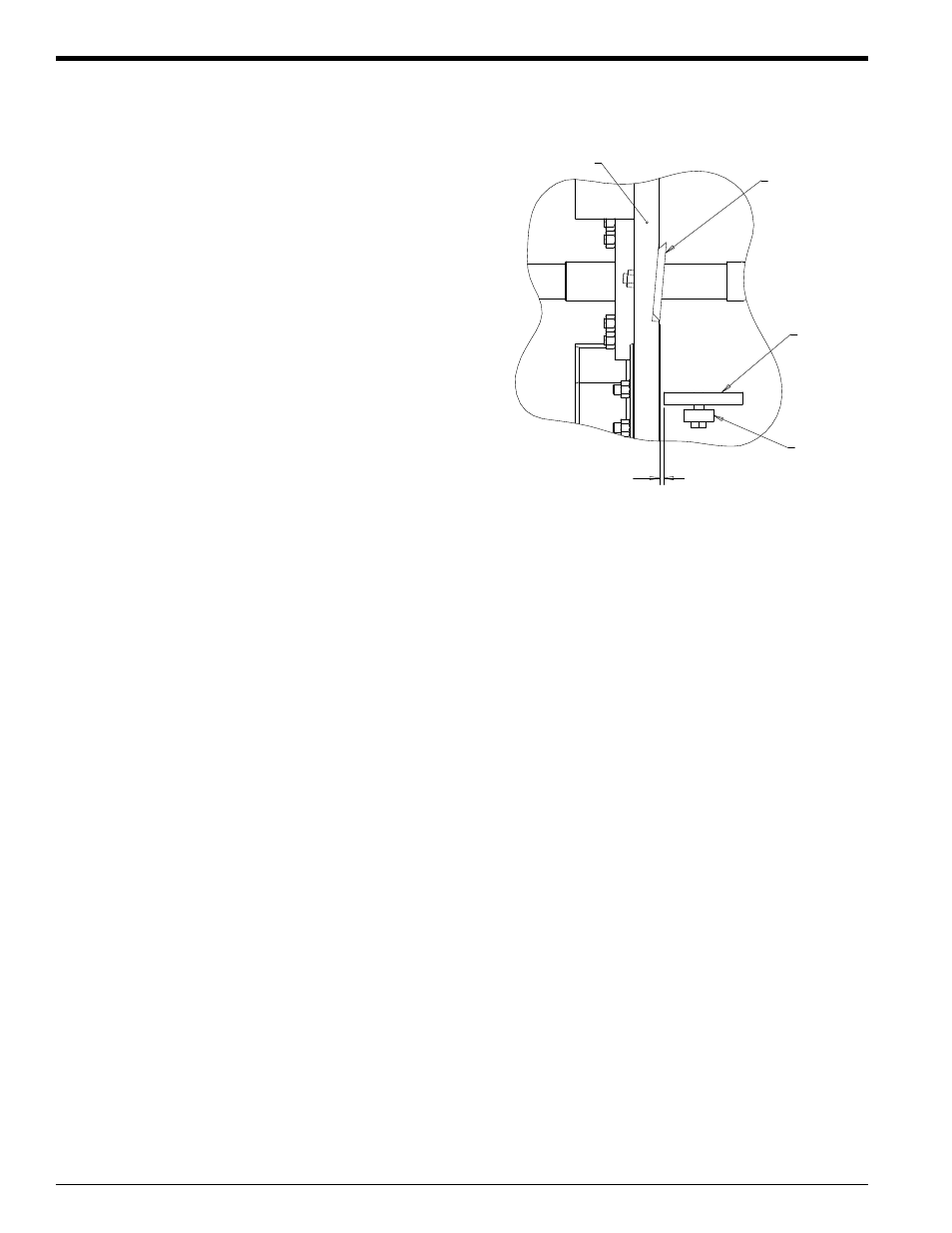

The chipping blades should clear the chipper block located

directly under the chipper chute by 1/16 inch. To adjust the

blade clearance, proceed as follows:

1.

Lift rotor access cover and expose rotor. Loosen the

three 1/2 inch bolts that hold the chipper anvil to the

frame (see Figure 5.3).

2.

Measure the amount of clearance between chipping

blades and chipping anvil from inside of housing. Adjust

inward or outward to desired measurement.

3.

Check clearance on all the blades.

4.

Tighten bolts on chipping anvil to 75 Ft-lb and resume

operation.

5.4 SETTING CHIPPER BLADE

CLEARANCE

1.

Remove large belt guard (three 5/16" bolts).

2.

Loosen bolts on hydraulic pump and remove the hy-

draulic pump belt, if equipped.

3.

To remove old drive belt, step down on foot clutch pedal

to take tension off belt. Remove old belt from pulleys.

4.

Install new drive belt on pulleys. Check alignment of

pulleys and adjust if needed. Release foot clutch pedal.

5.

Adjust the drive belt tension until the belt deflection at

the center of the belt is 7/16" when a 20 lb. load is

placed against the belt (see Section 5.5)

6.

Replace hydraulic pump belt, if equipped. Readjust hy-

draulic pump belt tension by sliding the hydraulic pump

in the mounting slots. Tighten bolts.

7.

Replace belt guard.

8.

Depress foot clutch pedal, start engine, release foot

clutch pedal to engage belt, and test unit. Readjust

pulleys and belt tension if needed.

5.5 REPLACING DRIVE BELTS

Check the condition of the drive belt annually or after every

30 hours of operation, whichever comes first. If the belt is

cracked, frayed, worn, or stretched, replace it. Only replace

belt with original banded type belt. Do not use single type

belts. Follow the procedure below to replace the drive belt.

SERVICE & MAINTENANCE

1.

Remove the two 3/8 inch retaining bolts holding the ac-

cess cover to the mainframe assembly.

2.

Tilt access cover over to allow access to rotor. Rotate

the rotor so that the bolts holding the chipper blades

are most accessible.

3.

Lock rotor assembly (see Figure 5.1).

4.

Remove the two hex head bolts holding the blade to the

rotor.

5.

Remove old blade, install new blade and torque to 75

Ft-lb. Repeat this procedure for each blade.

5.3 REPLACING CHIPPER BLADES

If the chipper blade does not extend beyond the edge of the

rotor chipping slot, follow the procedure below to replace

the chipper blade.

1/16" - 1/8"

ANVIL

CHIPPER

BLADE

ROTOR

ANVIL

SPACER

If chipping anvil edge is damaged or worn unevenly, remove

the three bolts holding the anvil and use one of the other

three edges. Adjust for correct measurement.

Figure 5.3 - Chipper Blade/Anvil Clearance

5.

When sharpening the blades be sure to maintain the

original 45 degree angle. Be careful when grinding so

that the blade material does not get too hot and change

color. This will remove the blade's special heat treated

properties. Use short grinding times and cool with wa-

ter. Try to remove an equal amount off each blade to

maintain balance.

6.

Reinstall blade and torque to 75 Ft-lb. Repeat this pro-

cedure for each blade.

(DISK)