4 assembly torque chart, Sae 2 bolt diameter "a" sae 5 sae 8 – Echo 76628S User Manual

Page 13

PN 14295-00 R

11

ASSEMBLY

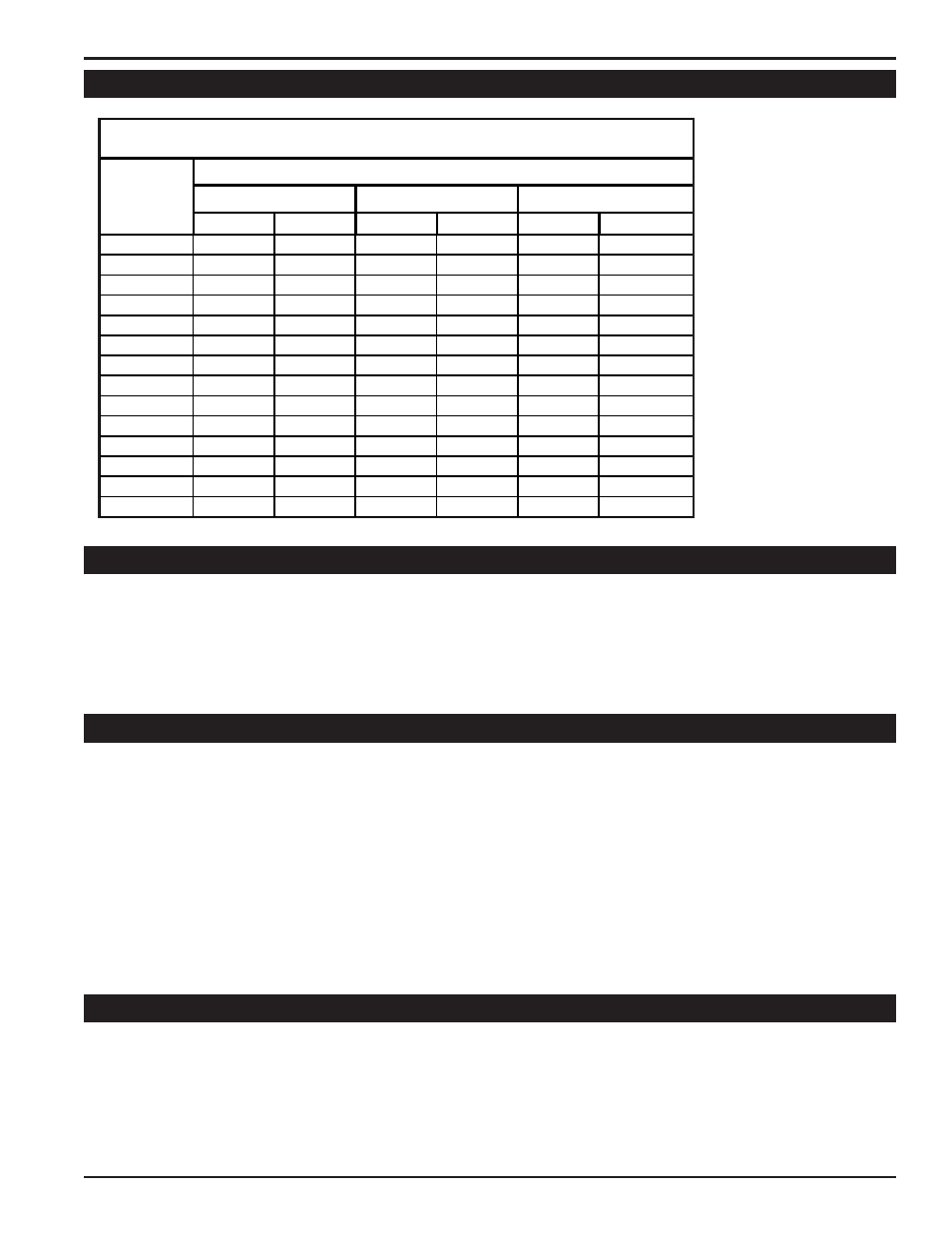

2.4 assemBly torQue Chart

UNIFIED INCH BOLT TORQUE VALUES (COARSE THREAD)

(unless otherwise specified in the manual)

Bolt Torque *

(N.m)

(ft - lb)

(N.m)

(ft - lb)

(N.m)

(ft - lb)

1/4"

7.5

5.5

12

9

17

12.5

5/16”

15

11

25

18

35

26

3/8”

27

20

44

33

63

46

7/16”

44

32

70

52

100

75

1/2”

67

50

110

80

150

115

9/16”

95

70

155

115

225

160

5/8”

135

100

215

160

300

225

3/4”

240

175

375

280

550

400

7/8”

240

175

625

450

875

650

1”

360

270

925

675

1300

975

1-1/8”

510

375

1150

850

1850

1350

1-1/4”

725

530

1650

1200

2600

1950

1-3/8”

950

700

2150

1550

3400

2550

1-1/2”

1250

930

2850

2100

4550

3350

SAE 2

Bolt

Diameter

"A"

SAE 5

SAE 8

2.5 traIler Wheels

2.7 traIler hItCh

2.6 DIsCharGe Chute

1. Remove the chipper from its shipping crate. Place the unit on a level surface before attempting to assemble it. See

the torque chart in the back of the manual for tightening torque of bolts and screws.

2. Raise the trailer several inches from the ground with a hoist or jack. Support the chipper securely.

3. Lift one wheel to a hub and align the wheel lug holes with the hub lug bolts. Thread the lug nuts (found in the parts

kit) into the holes and tighten the lug nuts to 75 ft. lbs. Follow a star pattern when tightening the lug nuts . Repeat this

step for the remaining wheel.

1. Attach the ball coupler to the hitch weldment using the provided 1/2” x 4” bolts and 1/2” washers and 1/2” nuts. Tighten

to proper torque.

2. Slide the hitch weldment into the hole in the frame, back to the 1/2” mounting holes.

3. Connect the hitch weldment to the frame using the two 1/2” x 4-1/2” bolts, 1/2” washers and 1/2” nuts. Tighten to

proper torque.

4. Check to make sure the tongue jack and safety chains are installed correctly.

1. The chute rotator is connected to the chipper frame first with two 3/8 bolts from the owners kit. Install but do not tighten.

Remove the top cover from the chute rotator to expose the rotator drive sprocket.

2. Attach the discharge chute to the mounting flange on the chipper frame. The square discharge chute will fit over the

round section of the chipper frame.

3. Place the discharge ring, and discharge retainer around the base of the mounting flange on the chipper frame.

4. Attach the discharge ring and retainer to the flange with the provided 3/8” x 1-1/4” bolts and nuts. Tighten to proper

torque.

5. Install the chain around the discharge ring and sprocket on the inside of the chute rotator. Connect chain with the

connector link.

6. Reassemble the top cover and tighten the 4 bolts.

7. Slide the chute rotator assembly back to remove chain slack and tighten the two attachment bolts.

8. torque all fasteners to proper values.