Danger, Caution – Echo 7812086 Owners Manual v.2 User Manual

Page 19

Bear Cat Owners Manual

15

SERVICE & MAINTENANCE

BEFORE INSPECTING OR SERVICING ANY PART OF THIS MACHINE, SHUT OFF POWER SOURCE, REMOVE KEY,

DISCONNECT THE BATTERY CABLES AND MAKE SURE ALL MOVING PARTS HAVE COME TO A COMPLETE STOP.

WARNING

5 . 3 S E T T I N G C H I P P I N G B L A D E

CLEARANCE

The four chipping blades should clear the chipping anvil by

3/16" + 1/16". If damage or uneven wear occurs on chipping anvil

edge, replace the anvil. To adjust the blade clearance:

Raise and secure the feed roller (Section 4.7).

Lift the rotor cover and secure with the lockup pin (Section

4.4).

Rotate the disk until a chipping blade is even with the

anvil.

Secure the disk to prevent movement during adjustment.

Loosen the three 1/2" x 1-1/2" bolts that secure the anvil to

the chipper housing.

Loosen the two 3/8" adjustment nuts located inside the

anvil backplate.

Tighten both 3/8" x 3-1/2" bolts equally to adjust the anvil.

Measure the clearance between the chipping blade and the

anvil from inside the feed chute. Continue to adjust both

bolts equally until there is a minimum 3/16" + 1/16" clearance

between the chipping blades and anvil.

Remove the disk lock and rotate the disk to ensure there is

proper clearance between all four chipping blades and the

anvil; insert disk lock and adjust anvil if necessary.

Once proper clearance is achieved, tighten the three

1/2" x 1-1/2" bolts to secure the anvil to the frame.

Tighten the two 3/8" adjustment nuts located inside the

anvil backplate.

Remove the disk lock and lower the rotor cover.

Remove the lockup pin, lower the feed roller and resume

operation.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

DANGER

Ensure that the feed roller is raised and secure before entering

the feed chute. Failure to do so can result in serious injury

or death.

5.5 CHECKING/ADDING COOLANT

The chipper is tested before shipping. In order to test the

equipment, the fluid levels are filled. However, before starting

the machine, check the coolant level in the radiator and coolant

reserve tank (if equipped) to ensure it is with in the proper

operating range (between FULL and FILL). Refer to the engine

owner's manual for specific instructions on checking and adding

coolant.

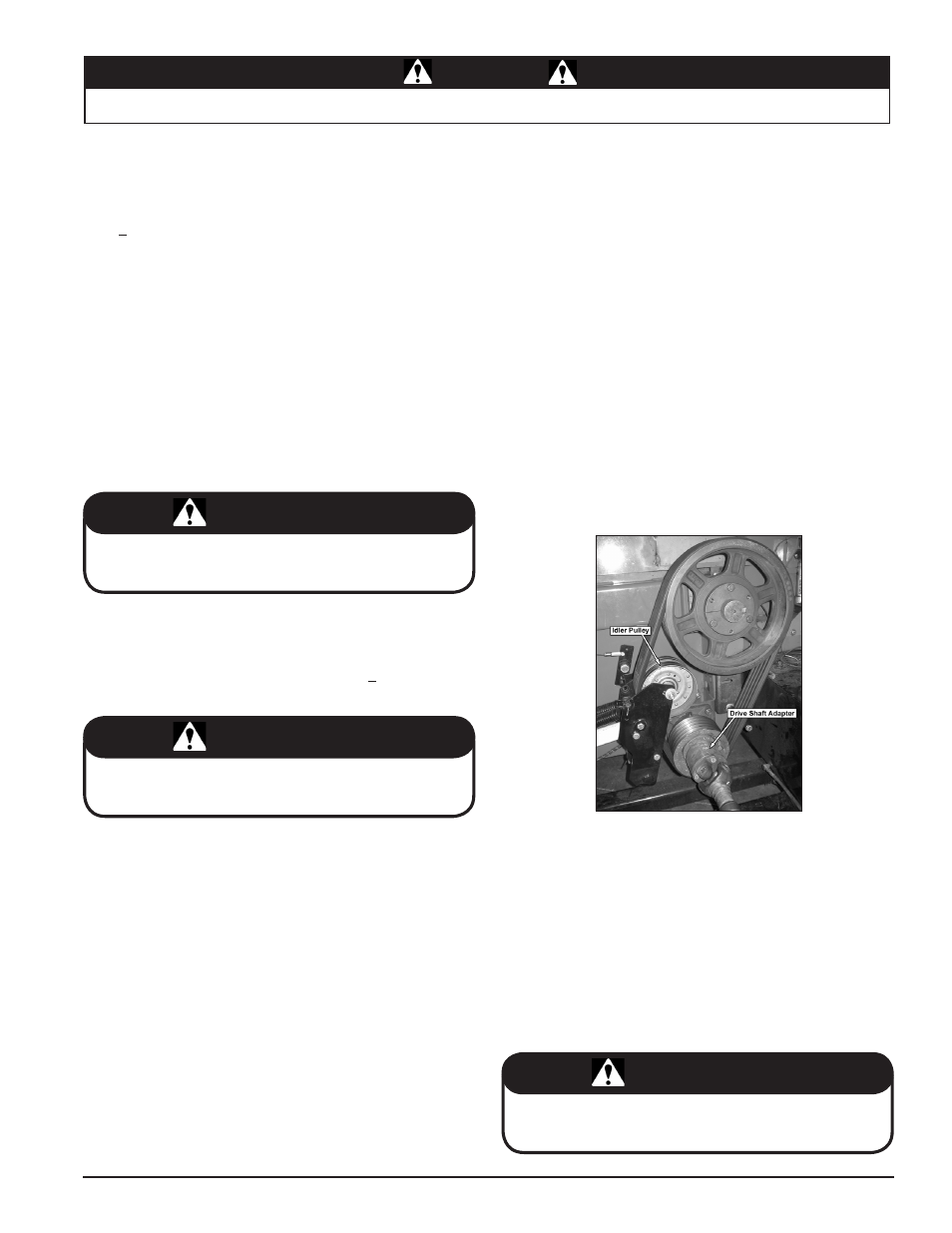

5.4 REPLACING THE DRIVE BELT

Replace the belt if cracked, worn, frayed, or stretched. To replace

the drive belt:

Remove the four 3/8" x 1" bolts, washers and nuts secur-

ing the PTO shield to the chipper housing and remove the

shield.

Remove the four 7/16" x 1-1/2" bolts and washers attaching

the PTO shaft to the drive shaft adapter; remove the adapter

from the lower belt sheave (Figure 5.3).

Remove the 7/16" 1-1/2" bolt, washer, nut and spacers

securing the idler pulley to the belt idler weldment; remove

the pulley.

Remove the drive belt and install the new belt.

Reattach the idler pulley.

Slide the drive shaft adapter onto the lower belt sheave and

reattach the PTO shaft to the adapter.

Attach the PTO shield to the chipper housing.

1.

2.

3.

4.

5.

6.

7.

Figure 5.3 - Replacing the Drive Belt

NOTE

If the anvil edge is damaged or worn unevenly, remove anvil

and use one of the other three edges. If all edges are damaged

or worn unevenly, replace the anvil.

CAUTION

Coolant is hot during and after operating chipper. Do not check

coolant level when fluid is hot. Wait until the fluid has cooled

before removing radiator cap.