Operation, Warning – Echo 7812086 Owners Manual v.2 User Manual

Page 14

Bear Cat Owners Manual

10

Section

#

As with any other piece of outdoor power equipment, getting

the feel for how your machine operates and getting to know the

best techniques for particular jobs are important to overall good

performance.

CHIPPING OPERATION

The chipping operation takes place on the rear of the machine,

where hardened steel chipper blades are mounted on a rotating

rotor assembly. Material fed into the chipper chute is sliced into

small chips and propelled out through a discharge tube.

4.1 STARTING DIESEL MODELS

Move the machine to a clear, level area outdoors before starting.

Do not operate in the vicinity of bystanders. Make sure the cutting

chamber is empty before starting.

Check engine oil level before starting.

Fill fuel the tank with fresh, clean diesel fuel. See the engine

owners manual for instructions on bleeding the fuel system

on initial start up or if fuel runs out.

Disengage the engagement handle.

Move the key switch to the PREHEAT position. Wait until

the glow lamp lights up to indicate that the glow plug has

completed pre-heating.

For chippers with a reset button on the control panel activate

the key switch to start the engine. Release the key switch

immediately when the engine starts. Do not crank engine

for more than 10 seconds.

For chippers with a Murphy switch, push in and hold the

Murphy switch until the oil pressure appears on the gauge.

Activate the key switch to start the engine. Release the key

switch immediately when the engine starts. Do not crank en-

gine for more than 10 seconds. Continue to hold the Murphy

switch until the engine has enough oil pressure to run.

With the engine at 1100 RPM, carefully engage the rotor by

slowly pushing the engagement handle up.

Allow the machine to reach full RPM (2600 RPM) before

starting to chip material.

1.

2.

3.

4.

5.

6.

7.

WARNING

Before operating your machine, be sure you read and

understand all safety, controls and operating instructions in

this Owner/Operators manual and on your machine. Failure

to follow these instructions can result in serious injury or

property damage.

Operation

WARNING

Allow the machine to come to complete stop before

inspection or servicing. The rotor is heavy and has inertia

built up that will allow the rotor to turn for some time after the

clutch has been disengaged. You can tell when the rotor has

come to a complete stop when there is no noise or machine

vibration present. You can reengage the clutch to slow the

rotor to a stop.

4.2 STOPPING THE CHIPPER

Lower the throttle to 1500 RPM by pushing down on the

throttle toggle switch located on the control panel and let the

rotor and engine slow down before releasing the belt.

Disengage the engagement handle to release belt.

Let machine idle for a few seconds.

Turn the key switch to the OFF position.

Allow machine to come to a complete stop.

1.

2.

3.

4.

5.

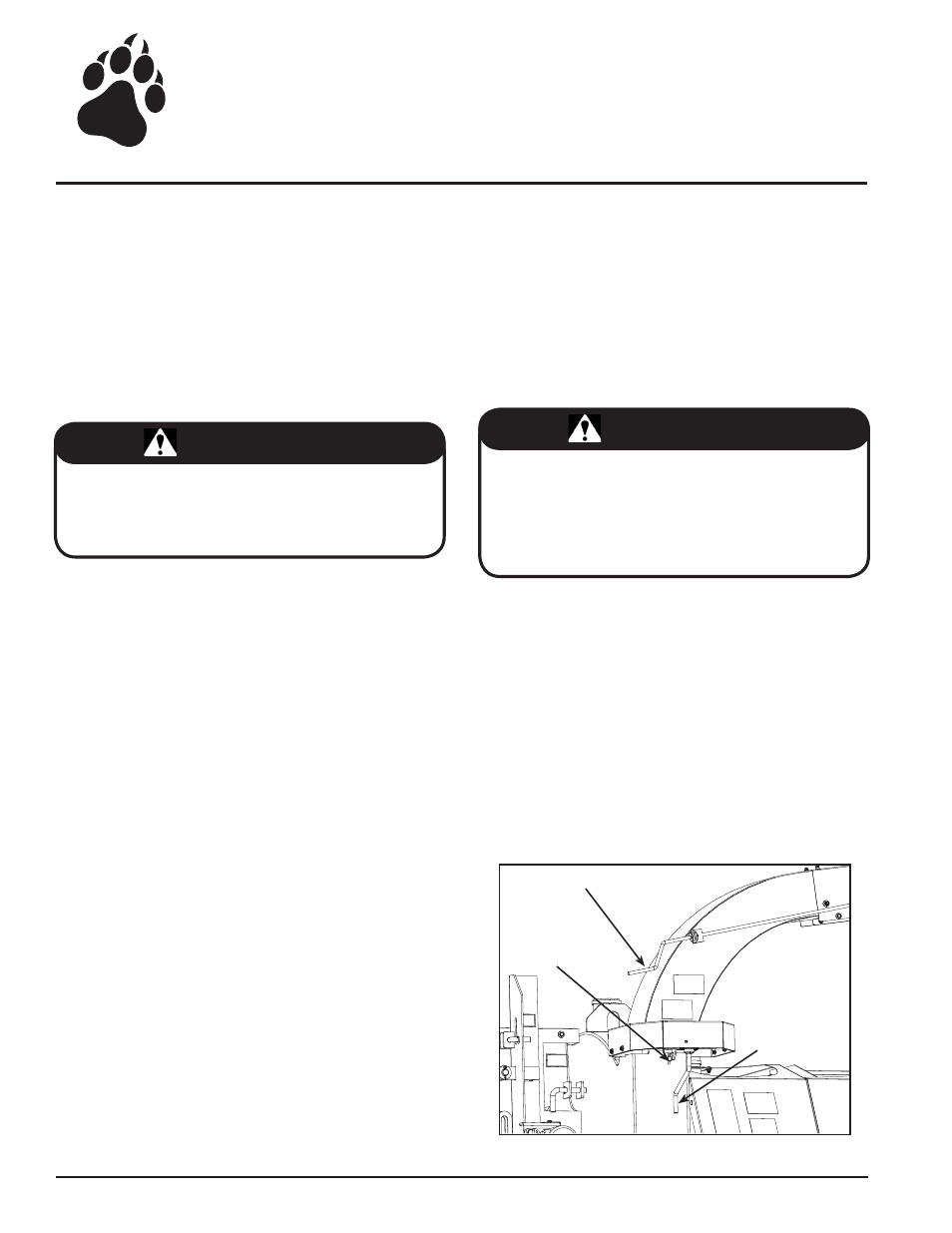

4.3 DIRECTING THE DISCHARGE CHUTE

The discharge chute can rotate 360° and lock into different

positions using the chute rotator. The discharge cap directs how

high and how far the chipped material blows.

To adjust the discharge chute, lift up the rotator lock. Turn the

discharge chute until the chute faces the desired position; let go

of the rotator lock and fine tune the position of the chute until the

lock snaps in place (Figure 4.1).

Adjust the discharge cap by turning the discharge cap crank.

Turning the handle clockwise will raise the position of the

discharge cap. Turning the handle counterclockwise will lower

the position of the discharge cap.

Figure 4.1 - Directing the Discharge Chute

Discharge Cap Crank

Discharge Chute

Crank

Rotator Lock

4