9 chipping guide, 8 chipper feed controller – Echo 7812086 Owners Manual v.2 User Manual

Page 16

Bear Cat Owners Manual

12

OPERATION

4.9 CHIPPING GUIDE

The Bear Cat chips a variety of materials into a more readily

decomposed or handled condition. The following guidelines can

help you get started.

Run unit at full operating speed before starting to chip

material.

Select limbs that are up to 12 inches in diameter. Trim side

branches that cannot be bent enough to feed into the feed

chute. Hold small diameter branches together in a bundle

and feed in simultaneously.

Using the feed roller lift makes feeding larger logs (8" and

above) easier and prevents the banging and slamming to

the top that can occur.

Exclude pieces of metal, rocks, bottles, cans, and other

foreign objects when feeding chipable material into the

machine.

Feed brush from the side of the feed chute, rather than from

the front. Step aside to avoid being hit by the brush moving

into the chipper.

Do not lean over the feed chute to push objects into the cut-

ting device. Use a push stick or brush paddle.

Never use shovels or forks to feed brush. They can be

chipped, are expensive to replace, and cause extensive

damage. In addition, metal pieces can be ejected from the

feed chute and cause serious injury or death.

Never feed brush into the feed chute with your feet.

Place limb, butt end first, into the feed chute until it contacts

the feed roller. The actual feed rate of the limb into the chip-

per will depend on the type of material fed and sharpness

of the cutting blades.

Stop the material feeding and allow the engine to recover if

the engine slows to where it may stall.

Remove the branch and rotate it before reinserting it into the

chute if the chipper jams.

Alternately insert and retract the limb or insert continuously

at a rate that will not kill the engine.

Chipping dead, dry material will create heat and dull the

chipping blades quickly.

Alternate green material with dry material to lubricate the

chipping blades for longer life and better performance.

The chipping blades will become dull and will require periodic

sharpening. Refer to the Service and Maintenance section

for sharpening instructions.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

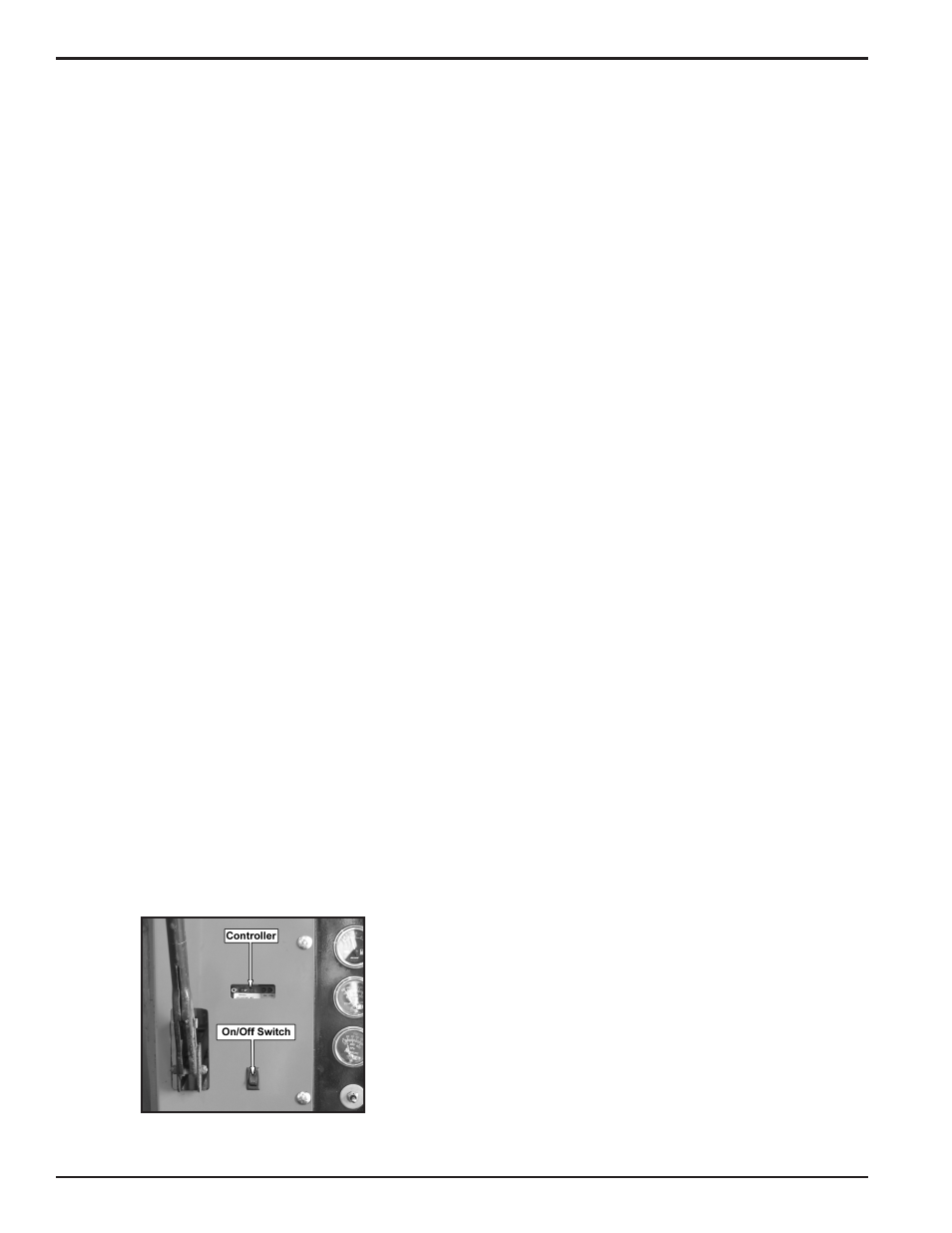

4.8 CHIPPER FEED CONTROLLER

The chipper is equipped with a pre-programmed feed controller.

The controller is located next to the control panel (Figure 4.7).

The controller serves a variety of functions including monitoring

chipper rotor RPM, controlling the feed roller, and providing

routine maintenance alerts. The controller has an on/off switch

located next to the control panel (Figure 4.7). If the controller

becomes damaged, the chipper will still run with the controller

shut off, however all of the controller functions will be disabled.

The control bar located on the feed chute will control the feed

roller.

The controller functions are further detailed below:

The controller operates the feed roller. The controller moni-

tors the RPMs of the chipper rotor and if it drops below the

preset range the feed roller stops. When the RPMs reach

an acceptable level, the feed roller will reengage.

The controller also has a “try again” feature. The controller

monitors the hydraulic pressure of the feed roller. If it senses

the level is too high (the feed roller becomes obstructed) the

controller will reverse the feed roller , removing the material

trying to be chipped. The controller will then engage the roller

into the forward position and try to feed the material again. If

this cycle continues, remove the obstruction manually. Trim

or reposition material if necessary.

At start up, the PWR/ERR LED on the controller will remain

off for 3 seconds, after which it will display either error codes

or power supply status. If error codes are present, the LED

will blink accordingly. If no error codes are present, the

power supply status is displayed:

100 Hour Service Error Code: Will blink every 100

hours of operation (blinks 10 times).

Blade Maintenance Error Code: Will blink every 15

hours of operation (blinks 5 times).

Power Supply Status Mode: ON (power ok), OFF

(low or no power), blinking once a second (power

above +30Vdc).

To reset service alerts, locate light green wire in engine

compartment next to the hour meter. Connect green wire

to red wire connector for five seconds.

NOTE: The RPM sensor on the rotor must flash or the controller

won’t work. Clearance between the sensor and the bolt must be

between 1/32” and 3/32”.

1.

2.

3.

•

•

•

4.

Figure 4.7 - Chipper Feed Controller