7 pto driveline lubrication, 8 clearing plugged rotor, Warning – Echo CH9540H Owners Manual v.2 User Manual

Page 20

PTO CHIPPERS

16

SERVICE & MAINTENANCE

8

h

8

h

8

h

8

h

8

h

5.7 PTo dRIvELINE LubRICATIoN

5.8 CLEARING PLuGGEd RoToR

WARNING

If the machine becomes plugged, lift the engagement

handle, shut off the engine, disconnect the spark plug

wire and allow the machine to come to a complete stop

before clearing debris. do not operate the machine

without proper guards and shields in place.

Feed

ROlleR

jAck

check

VAlVe

lOck PIN IN

STORAGe

POSITION

SuPPORT

BRAckeT

lOck PIN

POSITION

Feeding too large or too much material at once may plug

the chipper. To clear a plugged disk, proceed as follows:

disengage PTO and shut off tractor engine.

1.

Allow all moving parts to come to a complete stop.

2.

Remove the two 3/8” retaining bolts holding the access

3.

cover to the chipper frame and lift up access cover.

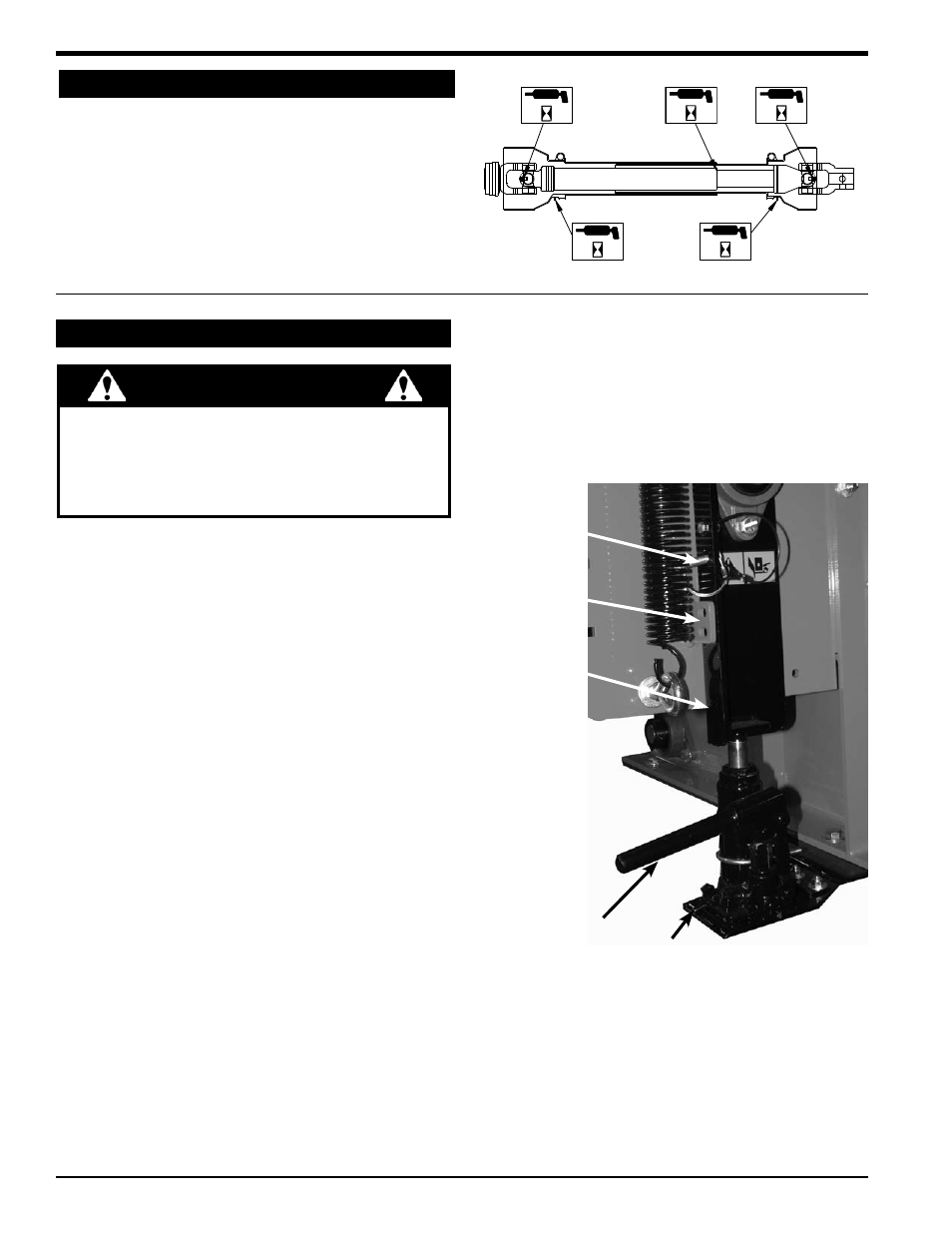

Remove the lock pin from storage position (see

4.

illustration on right).

Turn check valve clockwise to engage the jack pump.

5.

Pump the handle to raise the feed roller until the lock pin

6.

position aligns with one of the support bracket holes.

Secure the position by putting the lock pin through the

7.

support bracket and lock pin position.

clean the debris away from the chipper disk. Turn the

8.

disk by hand to be sure it is free to rotate. Be careful

to avoid the chipper blades when cleaning out the

debris.

Remove the lock pin and put it back in storage

9.

position. leAVING The lOck PIN IN ANY OTheR

POSITION MAY INTeRFeRe WITh Feed ROlleR

OPeRATION.

Turn the check valve counterclockwise to disengage

10.

the pump and lower the jack.

close access cover and replace bolts.

11.

Every 8 hours, lubricate PTO cross journals. Make sure grease

1.

purges through all four bearings.

every 8 hours, lubricate PTO inner tubes. Telescoping members

2.

must have lubrication to operate successfully. Telescoping members

without fittings should be pulled apart and grease should be added

manually with a brush.

every 8 hours, lubricate the PTO shield retaining bearing. Molded

3.

nipples on the guard near each guard bearing are intended as

grease fittings and should be

lubricated every 8 hours of

operation.