6 chipper controller, 7 feed roller speed control, 6 chipper controller 4.7 feed roller speed control – Echo CH9540H Owners Manual v.7 User Manual

Page 18

PTO CHIPPERS

14

OPERATION

4.7 FEED ROLLER SPEED CONTROL

This machine is equipped with a Plus 1 Controller. The

controller monitors the chipper disk RPM and regulates

the feed roller.

When chipper disk RPM drops too low, the feed roller

is stopped automatically to allow the chipper disk to

process material.

When the chipper disk returns to chipping RPM, the

feed roller will automatically reengage.

Try Again Feature: If the feed roller becomes obstructed,

the controller will reverse the feed roller momentarily

to clear the obstruction. The controller will then engage

the feed roller and feed the material again.

If this cycle continues, remove or reposition the material

manually.

Remember to sharpen blades frequently so material

will feed smoothly.

The controller light will flash the following codes (See

Sec. 6 for more information):

•

Normal Operating RPM: Steady green light

indicates engine has reached full RPM.

•

Feed Bar Not in STOP: Flashing red light indicates

operator must put feed bar in STOP position.

•

Service Code: Flashing amber light is a reminder

to check blade sharpness.

•

RPM Too Low: Flashing green light indicates

operator must increase engine RPM before starting

to chip.

•

Safety Bar Activated: Steady red light (European

models only).

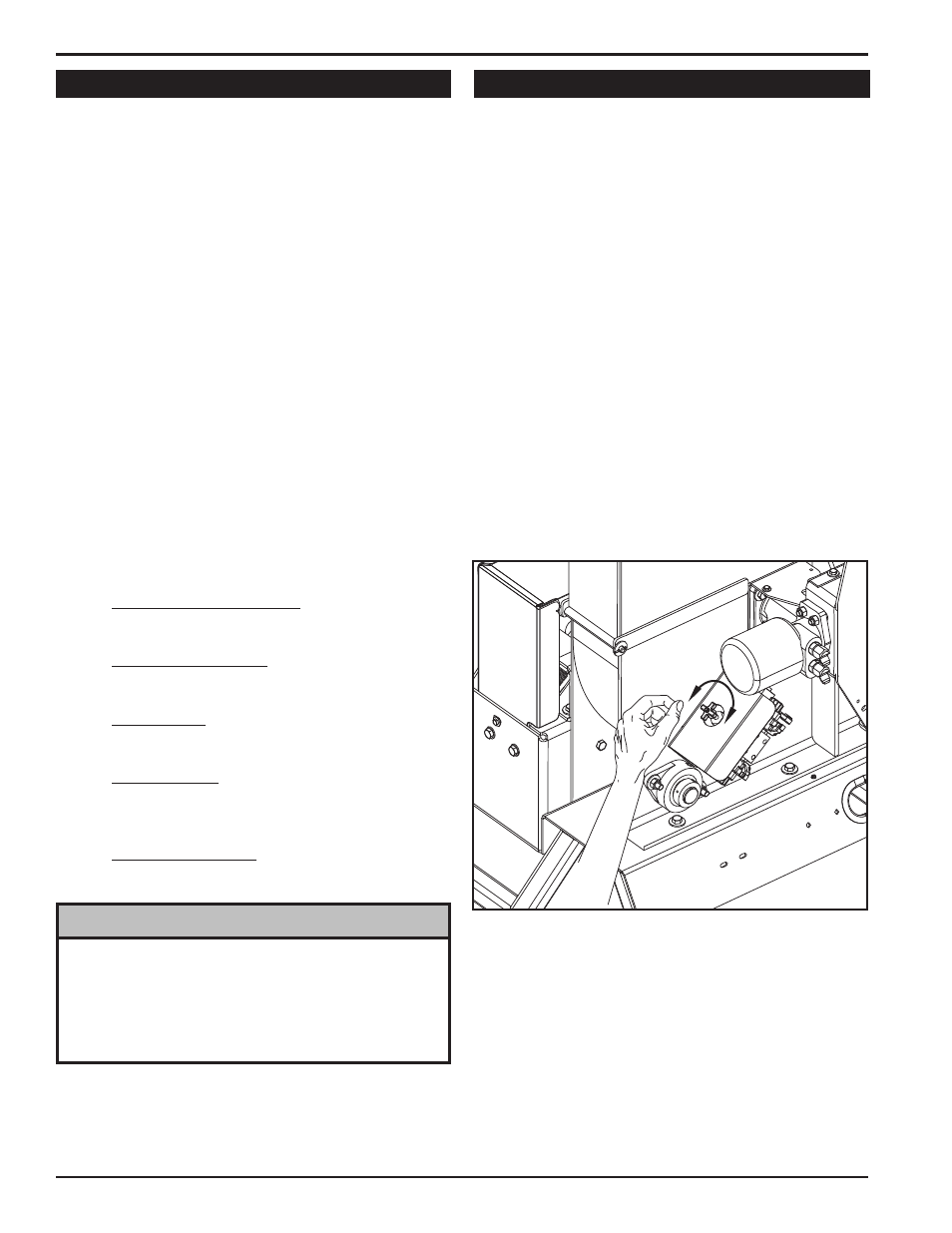

4.6 CHIPPER CONTROLLER

NOTE

The disk sensor and feed roller control bar sensors

must be set to the correct clearance or the chipper will

not operate. Set the clearance to 1/32” (the width of a

credit card). The sensor will flash with every rotation of

the chipper disk when the clearance is set correctly.

This machine is equipped with a flow control to vary

the speed of the feed roller. This allows the operator to

increase the feed speed when processing smaller material

and lower the speed when handling material close to the

maximum capacity of the machine. It is recommended that

operators start using the machine at the lower limits of the

speed control and slowly increase the speed, according to

the size and hardness of the material being chipped.

While occasional stopping and starting of the feed roller

is normal, frequent stopping and starting of the feed

roller and/or rapid decreases in chipper rotor rpms is an

indication that the feed speed is too high. Continued

operation under such conditions can result in plugging of

the discharge, belt damage, and inefficient operation.

Recommended Procedure:

Turn the flow control knob fully clockwise to bring the

feed roller to a stop. Turn the flow control knob counter

clockwise two full turns and begin feeding material into the

chipper. Adjust as needed.