Lift cylinder installation -6, Cylinder repair -6, Disassembly -6 – JLG M4069 Service Manual User Manual

Page 78: Barrel support -6, Cap screw removal -6, Rod support -6, Lift cylinder installation, 11 cylinder repair, Disassembly

SECTION 4 - HYDRAULICS

4-6

– JLG Lift –

3121639

Lift Cylinder Installation

1. Install lift cylinder in place using a suitable slings,

aligning barrel end attaching pin mounting holes on

lower arm assembly.

2. Using a suitable drift, drive the barrel end attach pin

through the mounting holes in the lift cylinder and

the lower arm assembly. Secure in place with bolt,

locknut and keeper shaft.

3. Remove cylinder port plugs and hydraulic line caps

and correctly attach lines to cylinder ports.

4. Extend the cylinder rod until the attach pin hole

aligns with those in the upper arm assembly. Using a

suitable drift, drive the cylinder rod attach pin

through the aligned holes, taking care to align the

pin retaining holes with the hole on the arm assem-

bly. Secure the pin in place with bolt, locknut and

keeper shaft.

5. Lower platform to stowed position and shut down

motor. Check hydraulic fluid level and adjust accord-

ingly.

NOTE: Always check hydraulic fluid level after completely

elevating and lowering machine.

4.11 CYLINDER REPAIR

NOTE: The following are general procedures that apply to

all of the cylinders on this machine. Procedures that

apply to a specific cylinder will be so noted.

Disassembly

DISASSEMBLY OF THE CYLINDER SHOULD BE PERFORMED ON

A CLEAN WORK SURFACE IN A DIRT FREE WORK AREA.

1. Operate the hydraulic power source and extend the

cylinder. Shut down and disconnect the power

source. Adequately support the cylinder rod, if nec-

essary.

2. If applicable, remove the cartridge-type holding

valve and fittings from the cylinder port block. Dis-

card o-rings.

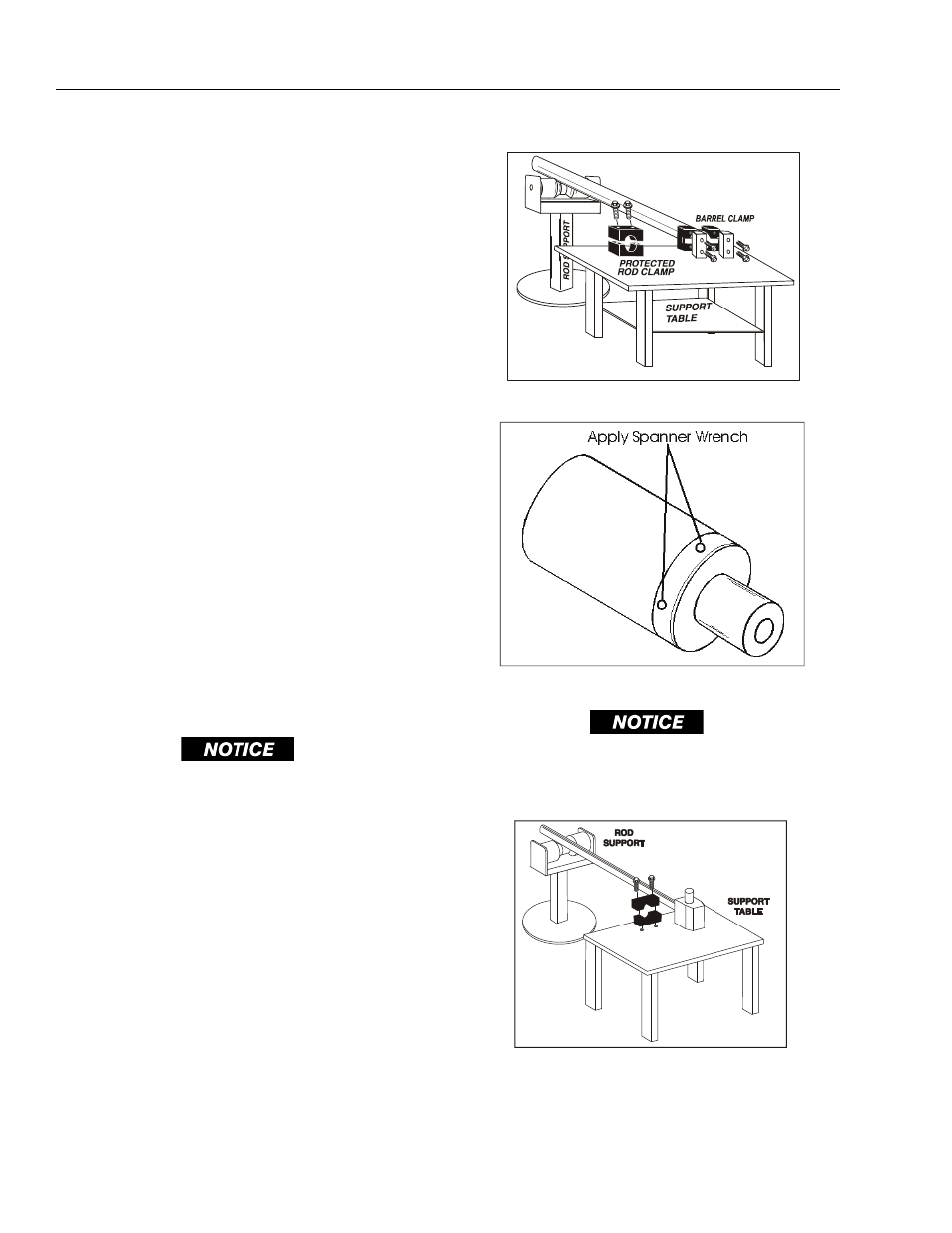

3. Place the cylinder barrel into a suitable holding fix-

ture.

4. To aid in realignment, mark cylinder head and barrel

with a center punch.

5. Using a suitable spanner wrench, loosen the span-

ner nut retainer and remove the spanner nut from

the cylinder barrel.

6. Attach a suitable pulling device to the cylinder rod

port block or cylinder rod end, as applicable.

EXTREME CARE SHOULD BE TAKEN WHEN REMOVING THE CYL-

INDER ROD, HEAD, AND PISTON. AVOID PULLING THE ROD OFF-

CENTER, WHICH COULD CAUSE DAMAGE TO THE PISTON AND

CYLINDER BARREL SURFACES.

Figure 4-1. Barrel Support

Figure 4-2. Cap Screw Removal

Figure 4-3. Rod Support