JLG 110HX ANSI Service Manual User Manual

Page 97

SECTION 2 - PROCEDURES

3120636

– JLG Lift –

2-73

Inspection

1.

Clean all parts thoroughly.

2.

Closely inspect all parts for excessive wear, cracks

and chips. Replace parts as necessary.

3.

Discard seals and o-rings.

4.

Closely inspect bearings and bearing contact sur-

faces. Replace as necessary.

NOTE: Bearings may be reused if, after thorough inspection,

they are inspection, they are found to be in good

condition.

Assembly

NOTE: Lubricate all seals and o-rings with clean hydraulic

oil prior to assembly.

1.

Press new rotary seal (1) into housing (7). Note the

direction of seal.

2.

Install new bearing (2) on shaft (4).

3.

Install shaft assembly and retaining ring (3) into

housing (7).

4.

Install dowel pins (17), spring retainer (16), and

springs (5 & 6) into housing (7).

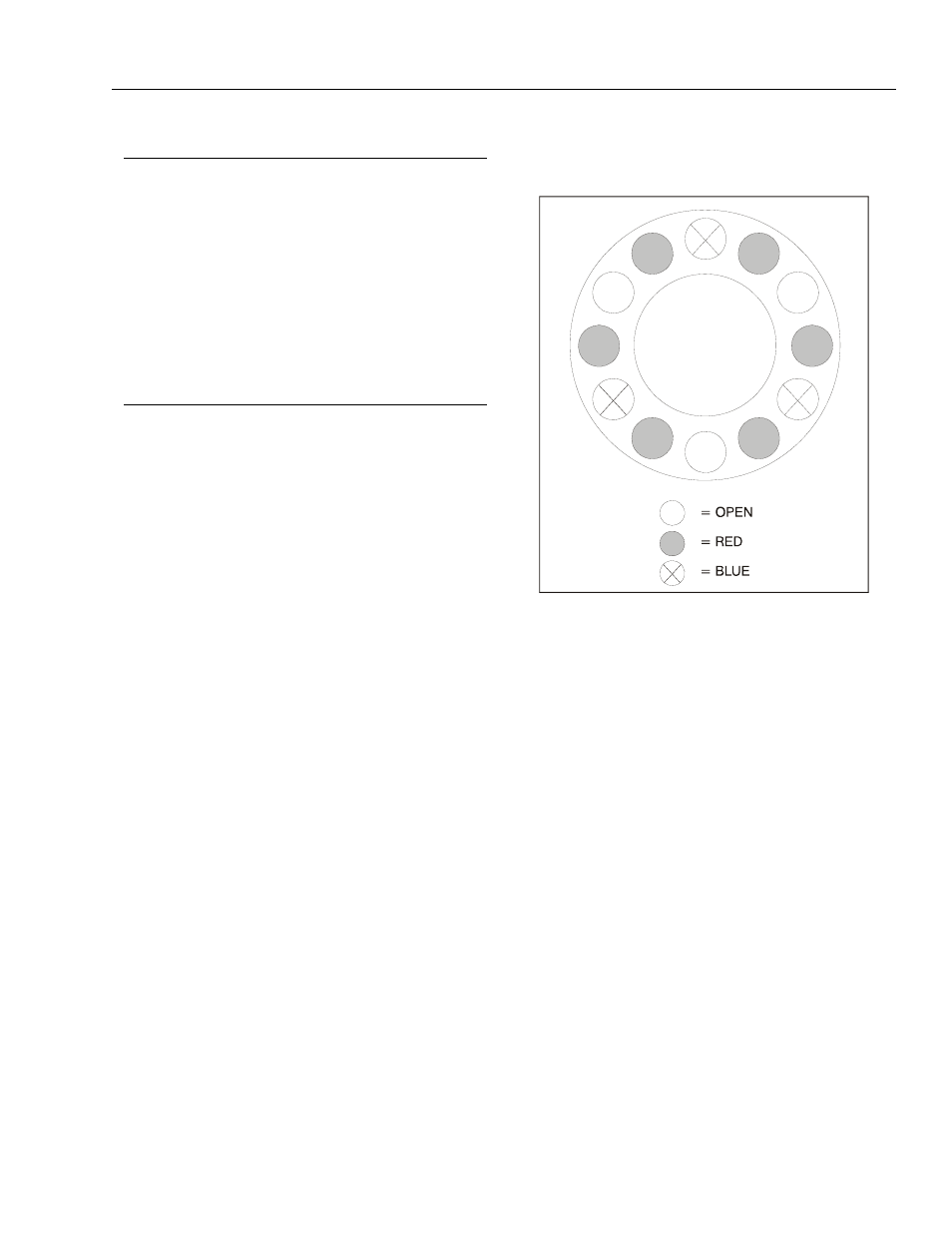

NOTE: Be sure to use the same number of springs and

spring pattern as recorded during disassembly.

5.

Position new large diameter return plate (8) in hous-

ing with tabs guided by dowel pins (17) until disc

rests on springs (5 & 6).

NOTE: Discs (8 & 23) and friction discs (22) should remain

dry during installation. No oil contaminate disc sur-

faces.

6.

Place new disc (22) on shaft (4) until it contacts

return plate (8).

7.

Add additional discs (23) as required to complete

assembly.

8.

Insert separators (10) in holes of return plate (8).

9.

Install new o-ring (19), new back-up ring (18), new o-

ring (20) and new back-up ring (21) on piston (24).

Insert piston (24) into end cover (13) being careful

not to shear o-rings or back-up rings.

10.

Install new case seal (11) in housing (7) then install

bleeder screw (14) in end cover.

11.

Position end cover (13) on housing (7) aligning

dowel pins (17) with holes in end cover.

12.

Insert capscrews (12) and tighten evenly to draw

end cover (13) to housing (7). Torque capscrews to

55 ft. lbs. (75 Nm).

Figure 2-30. Spring Loading