JLG 120-SXJ ANSI Service Manual User Manual

Page 36

SECTION 3 - CHASSIS & TURNTABLE

3-8

– JLG Lift –

3121105

g. Carefully lower the turntable onto the swing

bearing, ensuring that the turntable and bearing

align as noted in step i above.

IF COMPRESSED AIR OR ELECTRICALLY-OPERATED IMPACT

WRENCH IS USED FOR TIGHTENING THE BEARING ATTACH-

MENT BOLTS, THE TORQUE SETTING ACCURACY OF THE TOOL

SHOULD BE CHECKED PRIOR TO USE.

h. Apply a light coating of Loctite #277 to the new

bearing bolts, and install the bolts, washers and

nuts through the turntable and inner race of the

bearing.

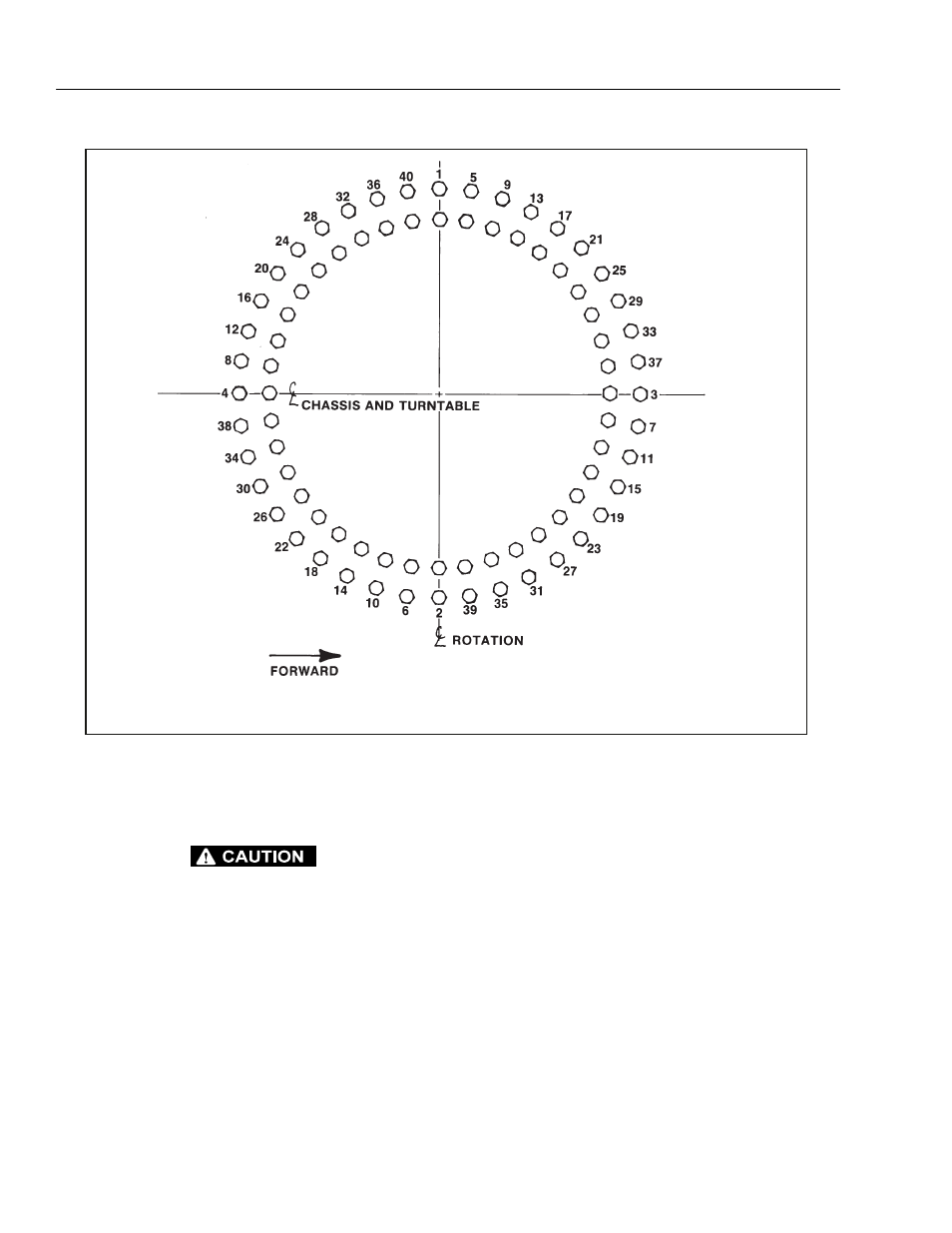

i.

Following the Torque Sequence diagram shown

in Figure 3-6., Swing Bearing Bolt Torquing

Sequence, tighten the bolts to an initial torque of

180 ft. lbs. (244 Nm). Then following the same

sequence tighten the bolts to a final torque of

240 ft. lbs. (325 Nm).

j.

Remove the lifting equipment.

k. Install the rotary coupling retaining yoke; apply a

light coating of Loctite Sealant Number TL277-

41 to the attaching bolts and secure the yoke to

the rotary coupling with the bolts and lockwash-

ers.

l.

Connect the hydraulic lines to the rotary cou-

pling as tagged prior to removal.

m. At ground control station, use boom lift control

to lower boom to stowed position.

n. Using all applicable safety precautions, activate

hydraulic system and functionally check swing

system for proper and safe operation.

INSTALL BEARING WITH FILL PLUG ON SIDE.

(AS CLOSE TO CENTERLINE OF ROTATION

AS POSSIBLE.)

NOTE:

Figure 3-6. Swing Bearing Bolt Torquing Sequence