Wheel and shaft maintenance, Structural maintenance, Operation checklist – Aerovent IM-166 User Manual

Page 3

Aerovent IM-166

3

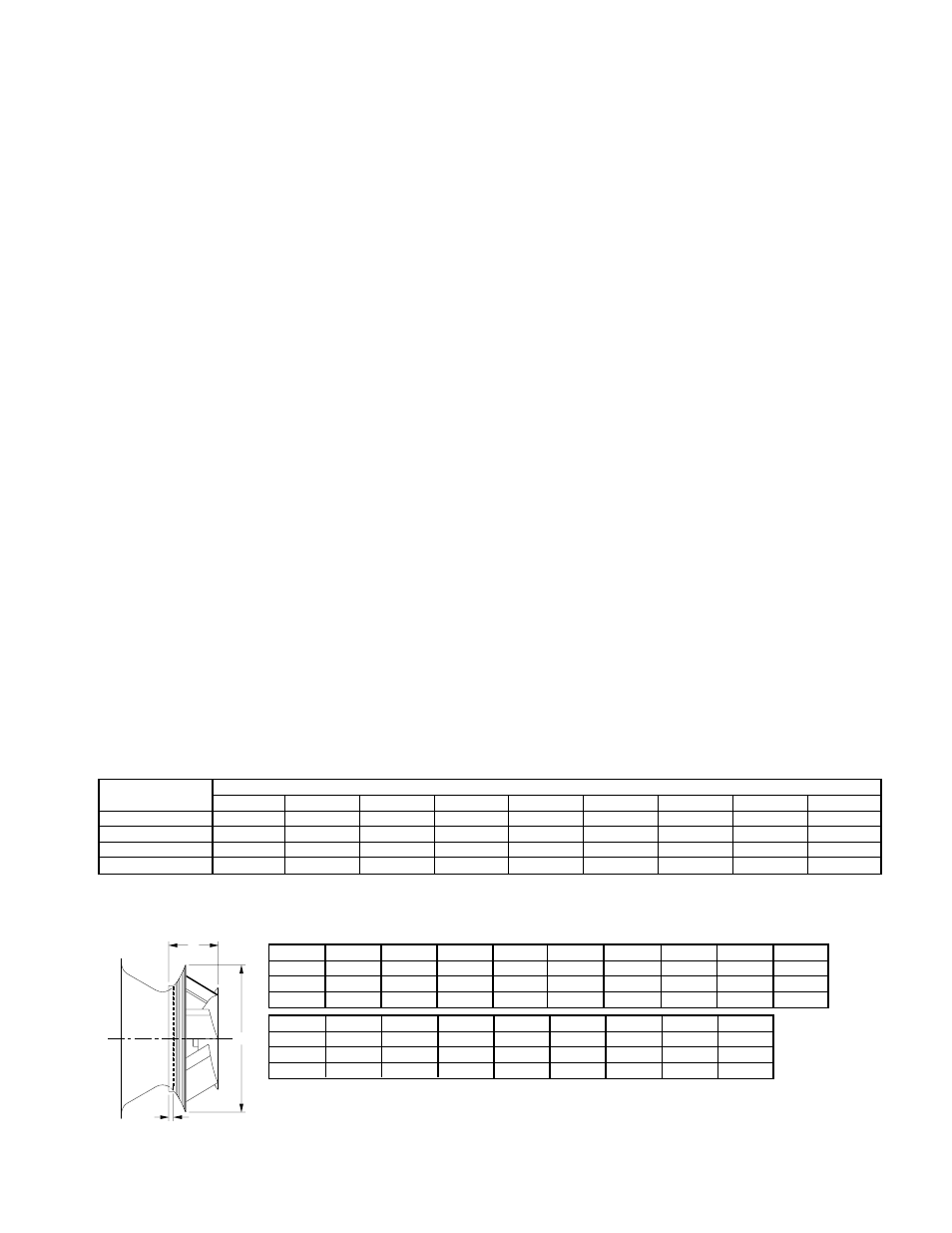

Table 2. Relubricating Schedule (Months) — Ball Bearing Pillow Blocks

SPEED (RPM)

SHAFT DIA.

500

1000

1500

2000

2500

3000

3500

4000

4500

1

⁄

2

"– 1

11

⁄

16

"

6

6

5

3

3

2

2

2

1

1

15

⁄

16

" – 2

7

⁄

16

"

6

5

4

2

2

1

1

1

1

2

11

⁄

16

" – 2

15

⁄

16

"

5

4

3

2

1

1

1

—

—

3

7

⁄

16

" – 3

15

⁄

16

"

4

3

2

1

1

1

—

—

—

conditions. See Table 2 for typical lubrication data.

However, every installation is different and the frequency

of relubrication should be adjusted accordingly.

On high moisture applications, the lubrication fre-

quency may need to be doubled or tripled to adequate-

ly protect the bearings. Double the relubrication fre-

quency on fans with vertical shafts.

Observation of the conditions of the grease expelled

from the bearings at the time of relubrication is the best

guide as to whether regreasing intervals and amount of

grease added should be altered.

Greases are made with different bases. There are

synthetic base greases, lithium base, sodium base, etc.

Avoid mixing greases with different bases. They could

be incompatible and result in rapid deterioration or

breakdown of the grease. The lubrication sticker identi-

fies a list of acceptable lubricants. All bearings are filled

with a lithium-based grease before leaving the factory.

When the fans are started, the bearings may discharge

excess grease through the seals for a short period of

time. Do not replace the initial discharge because leakage

will cease when the excess grease has worked out.

Sometimes the bearings have a tendency to run hotter

during this period. There is no reason for alarm unless

it lasts over 48 hours or gets very hot (over 200°F). When

relubricating, use a sufficient amount of grease to purge

the seals. Rotate bearings by hand during relubrication.

Wheel and Shaft Maintenance

Periodically inspect the shaft and wheel for dirt buildup,

corrosion, and signs of excess stress or fatigue. Clean

the components. If the wheel is removed for any reason,

make sure that it is securely attached to the shaft before

restarting the fan.

Structural Maintenance

All structural components or devices used to support or

attach the fan to a structure should be checked at

regular intervals. Vibration isolators, bolts, foundations,

etc., are all subject to failure from corrosion, erosion,

and other causes. Improper mounting can lead to poor

operation characteristics or fan fatigue and failure. Check

metallic components for corrosion, cracks, or other signs

of stress. Concrete should be checked to insure the

structural integrity of the foundation.

Operation Checklist

• Verify that proper safety precautions have been fol-

lowed.

• Electrical power must be locked off.

Check fan mechanism components:

• Nuts, bolts, setscrews are tight.

• Mounting connections are properly made and tight-

ened.

• Bearings are properly lubricated.

• Wheel, drives and fan surfaces are clean and tight-

ened.

• Rotating assembly turns freely and does not rub.

• Drives on correct shafts, properly aligned, and prop-

erly tensioned.

Check fan electrical components:

• Motor is wired for proper supply voltage.

• Motor was properly sized for power of rotating

assembly.

• Motor is properly grounded.

• All leads are properly insulated.

Trial “bump”:

• Turn on power just long enough to start assembly

rotating.

• Check rotation for agreement with rotation arrow.

• Listen for any unusual noise.

Run unit up to speed:

• Bearing temperatures are acceptable (<200°F) after

one to two hours of operation.

• Check for excess levels of vibration. Filter in read-

ings should be 0.15 inches per second or less.

After one week of operation:

• Check all nuts, bolts and setscrews and tighten if

necessary.

• Re-adjust drive tension if necessary.

Table 3. AMX Wheel-Funnel Overlap

B

A

C

Note: Use “B” dimension for positioning wheel.

SIZE

365

402

445

490

542

600

660

730

A

44.50

49.00

54.25

60.00

66.00

73.00

80.75

89.00

B

1.13

1.25

1.38

1.56

1.69

1.88

2.09

2.28

C

15.13

16.63

18.38

20.25

22.31

24.63

27.25

30.00

SIZE

150

165

182

200

222

245

270

300

330

A

18.25

20.00

22.25

24.50

27.00

30.00

33.00

36.50

40.25

B

0.56

0.63

0.69

0.75

0.88

0.97

1.06

0.94

1.03

C

6.19

6.75

7.56

8.31

9.13

10.19

11.19

12.38

13.63