Motor maintenance, Drive maintenance and installation, Motor support adjustment – Aerovent IM-166 User Manual

Page 2: Bearing maintenance

2

Aerovent IM-166

Motor Maintenance

The three basic rules of motor maintenance are:

1. Keep the motor clean.

2. Keep the motor dry.

3. Keep the motor properly lubricated.

Blow dust off periodically (with low pressure air) to

prevent motor from overheating.

Some smaller motors are lubricated for life. Lubrication

requirements are normally attached to the motor. Use

the motor manufacturer’s recommendations for relubrica-

tion. If this information is not available, the following

schedule may be used. Motors less than 10 HP running

about eight hours a day in a clean environment should

be lubricated once every five years; motors 15 to 40

HP, every three years. For motors in dusty or dirty

environments or running 24 hours a day: divide the

service interval by 4. Do not over lubricate.

Drive Maintenance and Installation

V-belt drives need periodic inspection, retensioning, and

occasional belt replacement. When inspecting drives,

look for dirt buildup, burrs or obstructions that can

cause premature belt or drive replacement. If burrs are

found, use fine emery cloth or a stone to remove them.

Be careful that dust does not enter the bearings.

Check sheaves for wear. Excessive slippage of belts

on sheaves can cause wear and vibration. Replace worn

sheaves with new ones. Carefully align sheaves to avoid

premature sheave failure.

Inspect the belts for wear. If fraying or other wear is

observed to be mostly on one side of the belts, the

drives may be misaligned. Reinstall the drives according

to the following instructions:

1. Slip (do not pound) proper sheave onto corresponding

shaft.

CAUTION: Placing fan sheave on motor can over-

speed wheel and cause structural failure.

2. Align sheaves with straightedge extended along

sheaves, just making contact in two places on out-

side perimeters of both sheaves.

3. Tighten sheave bolts (or setscrews if appropriate).

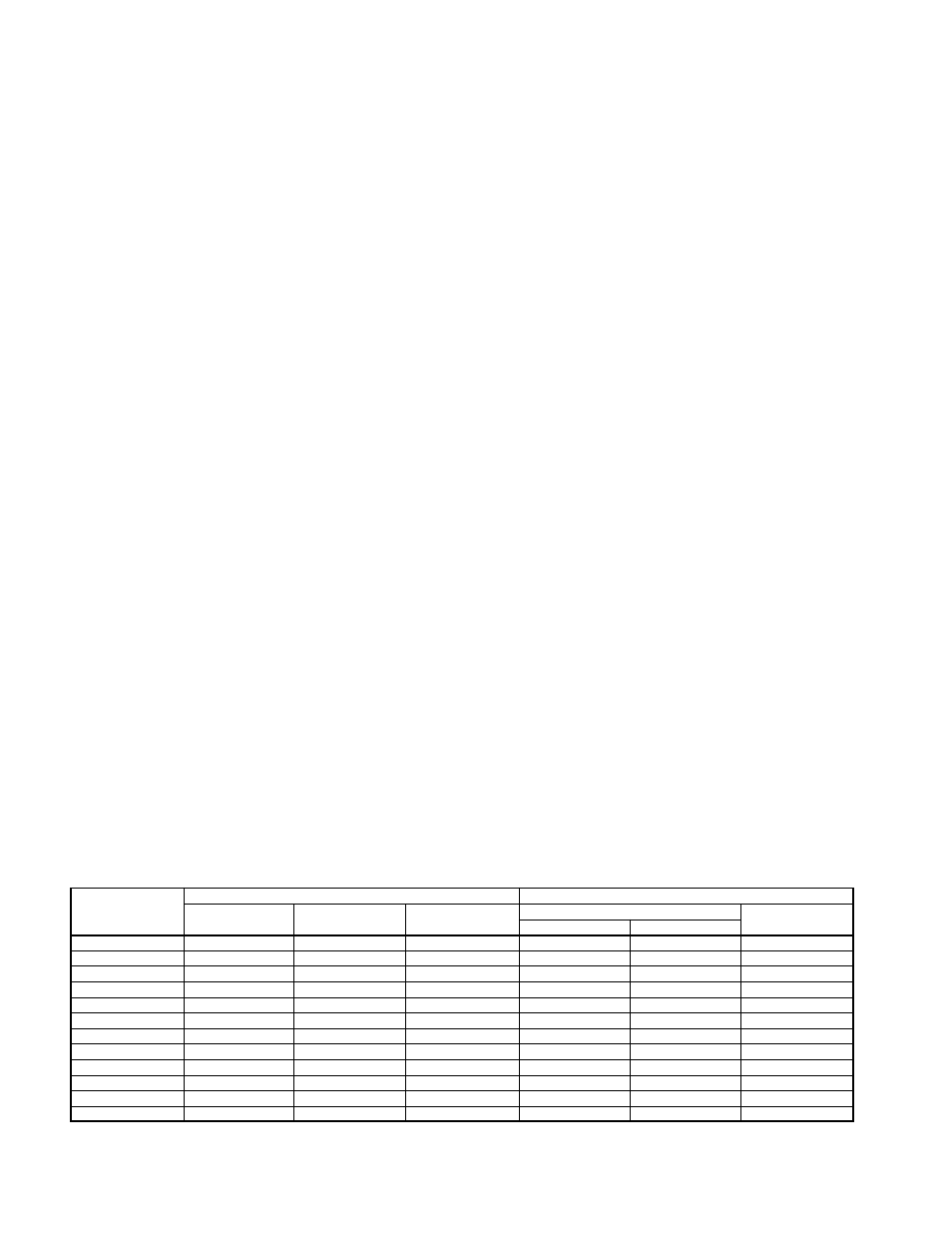

Table 1 can be used to determine the amount of

torque required.

4. Install a matched set of belts. Adjust the motor posi-

tion to obtain slack, install, and tighten belts. Using

a pry bar will damage belts.

5. Tighten belts to proper belt tension. Ideal tension is

just enough so that the belts do not slip under peak

load. When using drive tensioning data supplied by

V-belt drive manufacturers, new belts can be tensioned

to a value 50% greater than for normal operation. This

will reduce retensioning requirements after break-in.

Recheck sheave alignment after tensioning.

6. After initial installation of belts, recheck belt tension

again after a few days. (New belts require a break-in

period of operation.)

7. When replacing belts, replace the entire set. After

initial replacement and tensioning, recheck belt ten-

sion after a few days. (New belts require a break-in

period of operation.) Never use belt dressing on any

belts.

8. Fans that have motors and drives mounted at the

factory are trim balanced prior to shipment. This is

not possible on units that are shipped without motors

and drives. The addition of drive components in the

field can create unbalance forces. Aerovent recom-

mends final balancing of the unit after the drive

components are installed. Failure to do so may void

the warranty.

Motor Support Adjustment

Two different types of motor mounts, post and saddle,

are used on AMX Mixed Flow fans. Which mount to use

depends on the size of the fan and motor.

On the post type motor mount, the motor plate is

supported on four threaded rods. Belt tension is adjust-

ed by loosening the four nuts on top of the motor plate

and raising the motor plate by adjusting the four nuts

underneath it. The top nuts should then be tightened to

hold the motor plate in place.

On the saddle type motor mount, the motor pivots

on one side and adjustment of belt tension is achieved

by loosening the nuts on top of the motor plate on the

other side, then raising the motor plate by adjusting the

nuts underneath the motor plate. The nuts on top of the

motor plate should again be tightened to hold the motor

plate in place. Several holes are provided on the pivot

side, and the pivot point can be raised for gross belt

adjustment. If this adjustment is made, however, the

motor plate should be as parallel as possible to the fan

centerplane. Care should be taken to maintain drive

alignment and proper belt tension.

Bearing Maintenance

Proper lubrication of the fan drive bearings helps assure

maximum bearing life. All fans are equipped with decals

indicating relubrication intervals for normal operating

FASTENER

TAPER BUSHINGS

SIZE

BROWNING SPLIT

QD

GRADE 2

GRADE 5

GRADE 8

IN IRON

IN ALUM. HUB

FOR DRIVE

#10

—

—

—

—

—

5

1

⁄

4

-20

5.5

8

12

7.9

7.5

9

5

⁄

16

-18

11

17

25

16

13

15

3

⁄

8

-16

22

30

45

29

24

30

7

⁄

16

-14

30

50

70

—

—

—

1

⁄

2

-13

55

75

110

70

—

60

9

⁄

16

-12

—

—

—

—

—

75

5

⁄

8

-11

100

150

220

—

—

135

3

⁄

4

-10

170

270

380

—

—

—

7

⁄

8

-9

165

430

600

—

—

—

1-8

250

645

900

—

—

—

1

1

⁄

4

-7

500

1120

1500

—

—

—

Table 1. Tightening Torque (Ft.-Lbs.)

Tolerance: +5%

For wheel setscrews use Grade 2 values.

The above torque values are for nonlubricated fasteners.