Aerovent IM-391 User Manual

Page 4

4

Aerovent IM-391

Stack Extension Installation

1. Place supplied gasket around the perimeter of the

fan outlet.

2. Lower the stack extension onto the fan housing align-

ing the bolt holes on the two components. Allow for

gasket to compress naturally prior to securing fan

housing to the adjacent component.

3. Install 316 stainless steel hardware (provided) in all

mounting holes. Use a commercially available anti-

seizing compound formulated for 316 stainless steel

to hardware.

Windband Installation

1. Using the windband lifting lugs, raise the windband

above the outlet of the fan assembly. Align the sup-

port brackets with the fan assembly discharge

2. Using caution not to swing the windband, insert the

316 stainless steel mounting hardware (provided) coat-

ed with anti-seize compound to join the two compo-

nents.

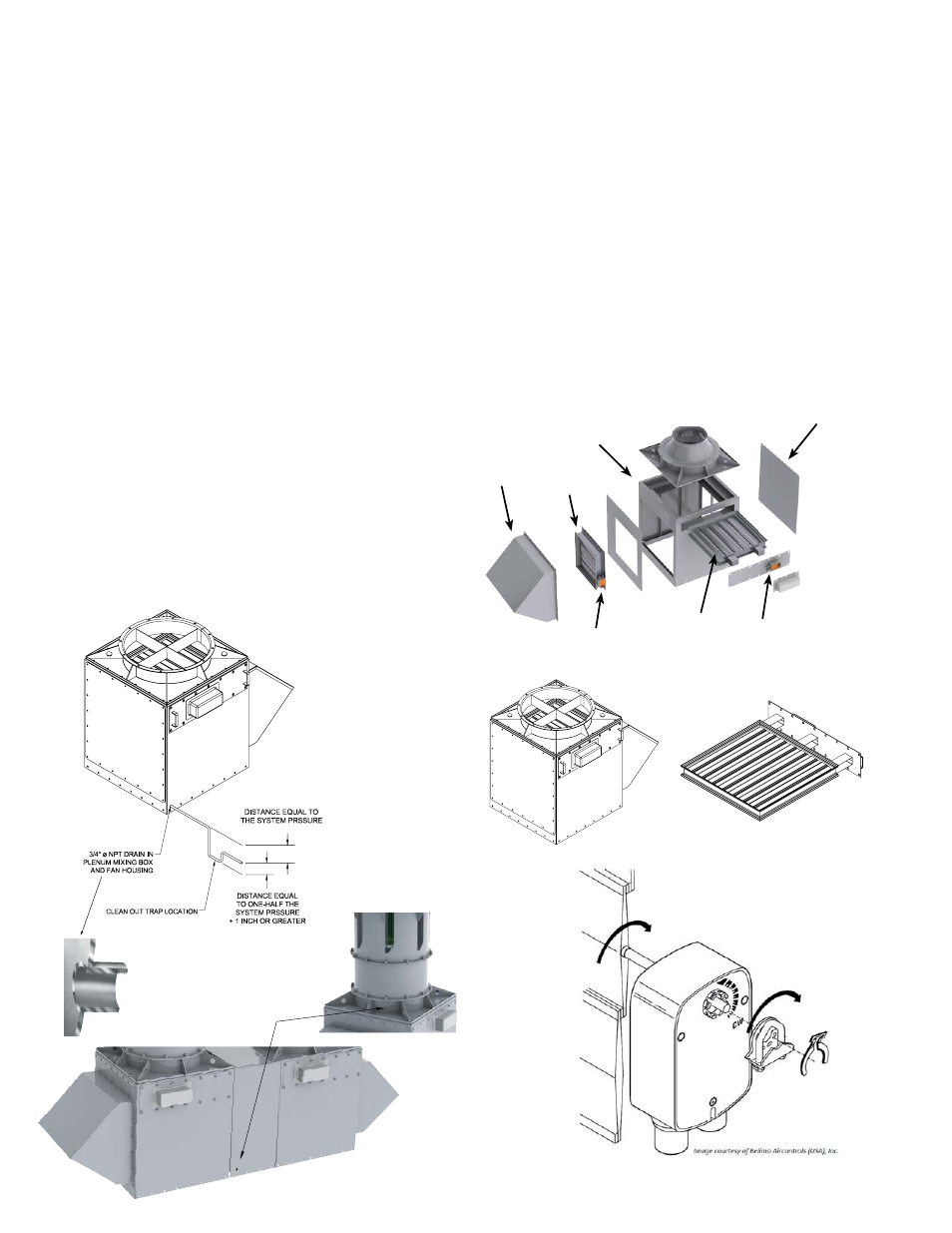

Drain Connection/Installation

Each section of the plenum mixing box as well as the

fan housing contains a 3/4" NPT drain pipe for connect-

ing to drainage system to ensure safe routing of any

liquid that may form in the system. Due to the potential

of hazardous chemical contamination, proper disposal of

liquids is required (by customer).

Note:

• A minimum of 1" of water must be placed in trap prior to

start-up to create proper “lock” of system pressure.

•

Drain should periodically be cleaned out for proper op-

eration.

Damper and Actuator Installation

Access to the Isolation Damper is obtained through

opening the slide out door on the side of the plenum.

Remove bolts from face of slide out door and remove

damper/door assembly for inspection and maintenance.

The 2-Position spring return actuator is attached to the

damper shaft through the slide out door in a Nema 4

enclosure and can be removed with the damper/door as-

sembly. Wiring is completed through knockouts in Nema

4 enclosure around the actuator.

Access to Bypass Damper and Modulating Actuator for

removal is obtained by removing the weatherhood cover-

ing the damper. Damper is attached to plenum face with

standard zip screws. An inspection door is available on

the side of the weather cover for standard inspection and

maintenance of the damper. Wiring for the modulating

actuator is fed through the knockouts in the weather-

hood.

3/4" NP DRAIN IN PLENUM

MIXING BOX AND FAN

HOUSING

Figure 5. Drain

Figure 6. Damper and Actuator Assembly

PARALELL BLADE

ISOLATION DAMPER

MODULAR MIXING

PLENUM BOX

ACCESS DOOR

2-POSITION SPRING

RETURN ACTUATOR

MODULATING ACTUATOR

WEATHER

HOOD

OPPOSED BLADE

BYPASS DAMPER