Inspection and receiving, Handling and rigging, Unit storage – Aerovent IM-391 User Manual

Page 2: Installation

2

Aerovent IM-391

INSPECTION AND RECEIVING

All Aerovent products are carefully constructed and

inspected before shipment to insure the highest standards

of quality and performance. Compare all components with

the bill of lading or packing list to verify that the proper

unit was received. Check each unit for any damage that

may have occurred in transit. Any damage should be

reported immediately to the carrier and the necessary dam-

age report filed.

HANDLING AND RIGGING

Handling of all air moving equipment should be conducted

by trained personnel and be consistent with safe handling

practices. Verify the lift capacity and operating condition of

handling equipment. Maintain handling equipment to avoid

serious personal injury.

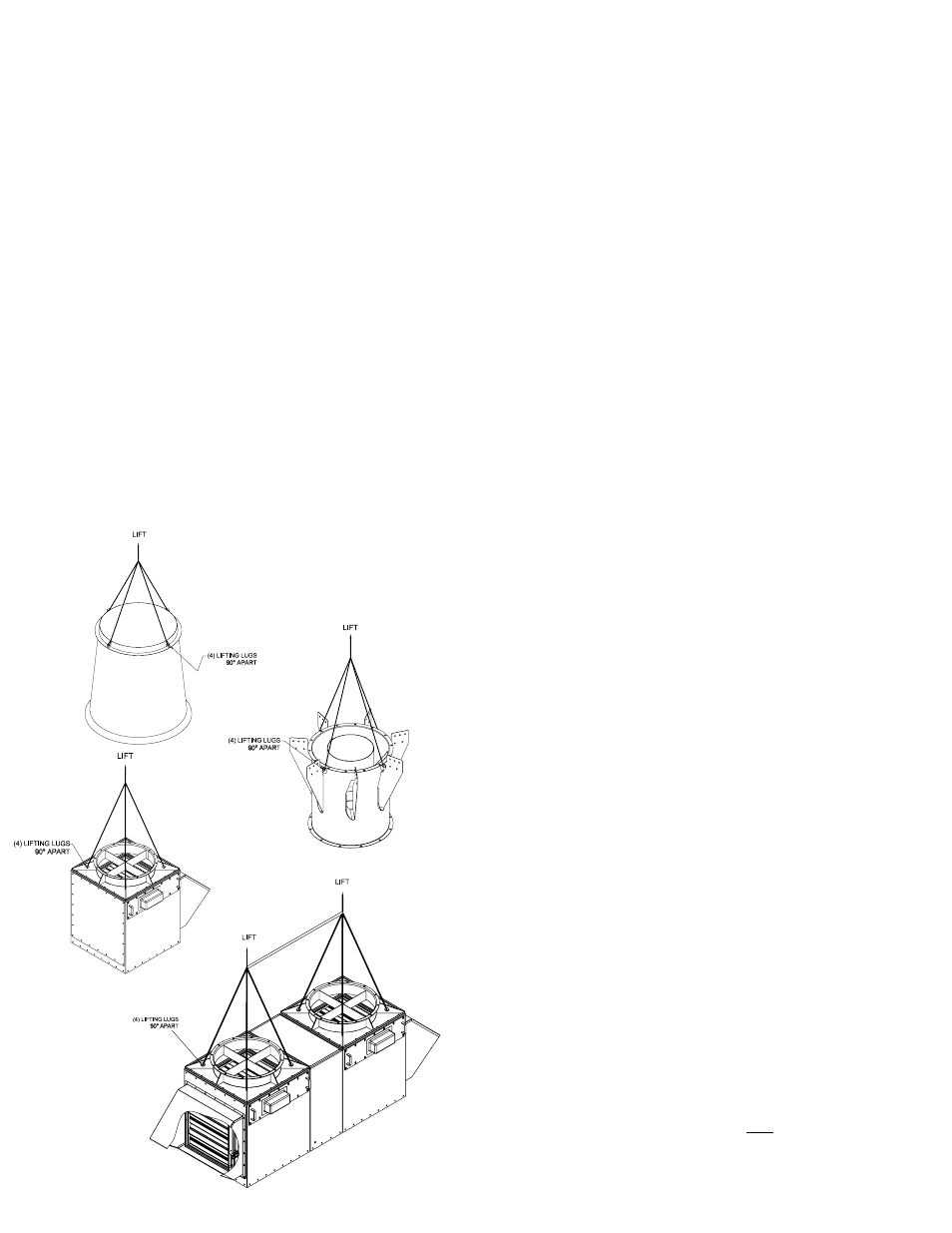

Units shipped may be lifted with slings and spreader bars.

Use well-padded chains, cables or nylon straps (see Figure

1). On most units, lifting lugs are fashioned to protect the

fan and fan housing from damage. Never lift a fan by the

inlet or discharge flange, shafting or drives, wheel, motor

or motor base, or in any other manner that may bend or

distort parts.

Mixing plenum boxes configured for multiple fans mounted

on a common unit are modular in design and may be

broken down into smaller segments for ease of installation

and handling.

UNIT STORAGE

If fan installation is to be delayed, store the unit in an

environmentally stable and protected area. During storage,

the fan should not be subjected to vibration from external

sources or bearing damage may occur. The unit should be

reasonably protected from any accidental impacts. Cover

the fan to protect coatings and to prevent any foreign

material or moisture from entering the inlet or discharge.

Take care to protect the motor, drives and bearings.

Extended storage requires monthly inspections. Check for

corrosion or damage to the unit and for debris within the

fan.

Bearings tend to take on moisture if the atmosphere in

which they are stored is not at a constant temperature. To

avoid corrosion, it is necessary to keep the bearings full

of grease and to rotate them periodically. Even when full

of grease, bearings will take on moisture, so it is necessary

to purge the bearings with new grease to expel moisture

every thirty days. It is recommended that the bearings be

purged with grease while being rotated by hand. Do not

use high pressure greasers as they may ruin the bearing

seals.

The drives and belts should be removed if the fan is to

be stored for a prolonged period. The drives should be

labeled for service and stored in a dry place. Belts should

be removed, coiled without kinks, placed in a heavy car-

ton, and stored in a dry, well-ventilated place. To prevent

belt deterioration storage conditions should not exceed

85°F and 70% humidity. If belts show signs of deteriora-

tion, they should be replaced prior to startup.

Motors should be stored in a clean, dry, vibration-free

location. The packaging should be opened up enough to

allow air circulation around the motor. The winding tem-

perature should be kept slightly above that of the sur-

roundings to prevent condensation. This can be accom-

plished by energizing the internal heaters, if the motor is

so equipped, or by using space heaters. If it is impossible

to heat the windings, the motor should be wrapped

tightly with a waterproof material which also encloses sev-

eral bags of desiccant. Replace the desiccant regularly to

prevent moisture problems. The motor rotor should also be

rotated regularly (monthly) to assure the bearing parts are

well greased.

Start-Up – When the unit is removed from storage, all fan

bearing grease should be purged and replenished with

fresh grease as per the lubrication decal. The motor should

be measured to verify that the resistance is still at a sat-

isfactory level compared to the value recorded prior to

storage.

INSTALLATION

Pre-Installation Checklist

Prior to fully assembling and installing, inspect the fan and

ancillary components to ensure it is in working order.

• Check all external and internal hardware on the fan,

wheel, bearings, drive motor base and accessories for

tightness.

• Rotate the fan wheel by hand and assure no parts are

rubbing. Adjust components prior to installation as ad-

justments are easier while lower to grad.

• Check proper wheel clearances to be sure near toler-

ance. The wheel will need to be realigned after instal-

lation, therefore, clearances should be near tolerance.

Figure 1. Lifting Locations