Warning – Snorkel SR3084SL User Manual

Page 47

Chapter 9 – Stowing and Transporting

SR3084SL – 8210037

43

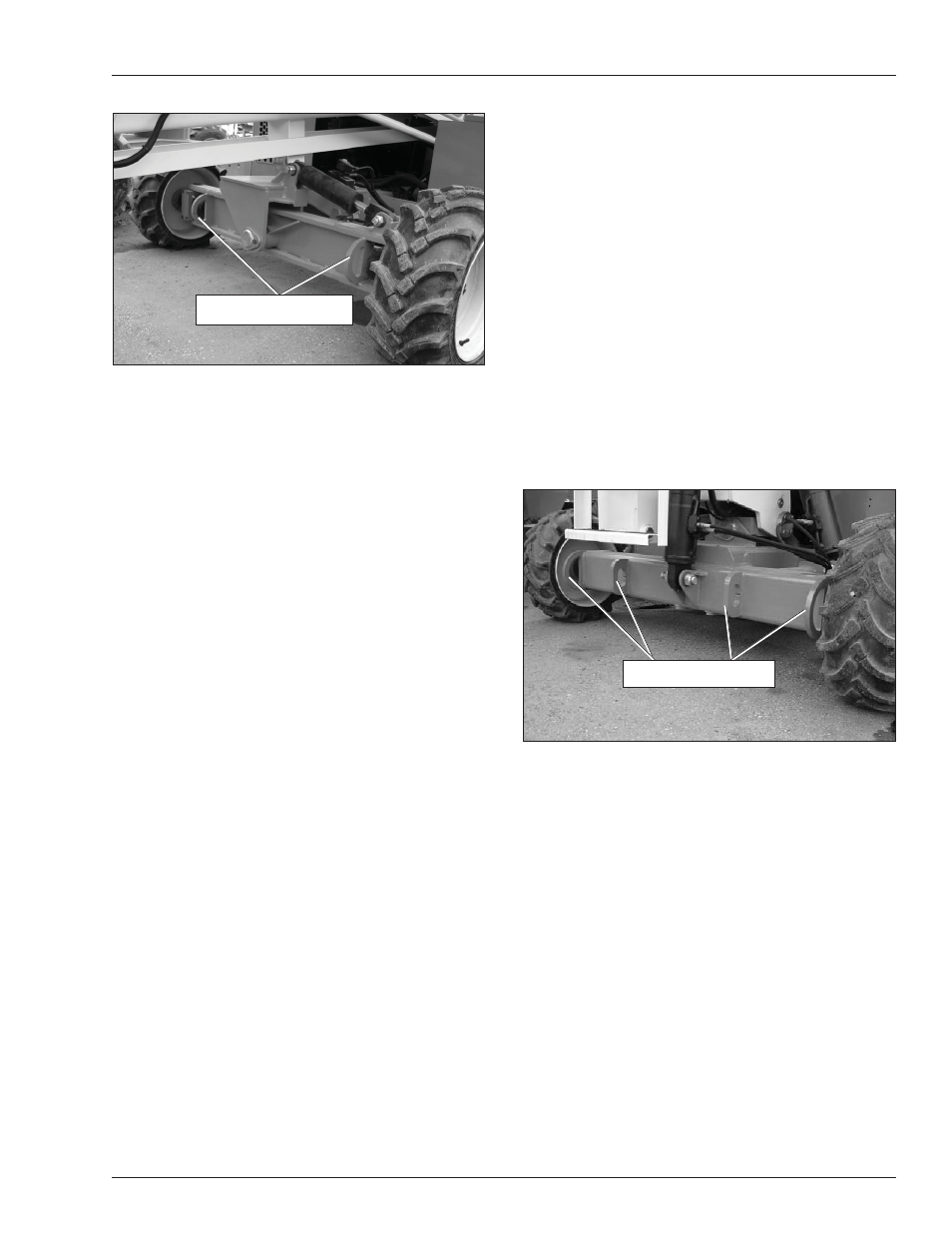

Figure 9.4 – Front Tie-Down/Lifting Lugs

9. Remove the wheel chocks and use the winch to

position the aerial platform on the transport vehicle.

A

Warning

The aerial platform is free to move when the brakes

are released. Death or serious injury could result.

Re-enable the brakes before operating the aerial

platform.

10. After moving the aerial platform, turn the free-wheel-

ing valve counterclockwise until the valve is fully

open. Refer to Figure 9.3.

11. After unloading the aerial platform from the transport

vehicle, verify that the drive system and brakes oper-

ate properly before operating the aerial platform.

Hoisting

Use a four point sling arrangement attached to the lifting

lugs when hoisting the aerial platform. Machine damage

can occur if the sling is attached anywhere else.

A

Warning

The potential for an accident increases when the

aerial platform is lifted using improper equipment

and/or lifting techniques. Death or serious injury

could result from such accidents. Use proper equip-

ment and lifting techniques when lifting the aerial

platform.

Know the weight of the aerial platform and the capacity

of the lifting devices before hoisting.

Lifting devices include the hoist or crane, chains,

straps, cables, hooks, sheaves, shackles, slings, and

other hardware used to support the machine.

The empty vehicle weight is stamped on the serial

number placard and is listed in Chapter 2.

y

y

Tie-Down/Lifting Lugs

Tie-Down/Lifting Lugs

The user assumes all responsibility for:

Making sure the equipment used is capable of sup-

porting the weight of the aerial platform.

Making sure all manufacturer’s instructions and warn-

ings, regulations and safety rules of their employer

and/or any state or federal law are followed.

Use the following procedure to hoist the aerial platform

onto the transport vehicle:

1. Properly stow the aerial platform.

2. Inspect the front lifting lugs and the rear lifting lugs

(refer to Figures 9.4 and 9.5) to make sure they

are free of cracks and are in good condition. There

are four lugs on the rear of the chassis and two on

the front. Have any damage repaired by a qualifi ed

service technician before attempting to hoist the

machine.

Figure 9.5 – Rear Tie-Down/Lifting Lugs

3. Remove all personnel, tools, materials, or other loose

objects from the platform.

4. Connect the chains or straps to the lifting lugs using

bolted shackles. Hooks that fi t properly in the lugs

and that have latching mechanisms to prevent them

from falling out under a slack line condition may also

be used.

Do not run the sling cable through the lifting lugs.

Cable damage and/or failure can result from the

cable contacting the sharp corners of the lug.

There is no effective way of putting a corner

protector in the hole of the lug.

5. Use spreader bars of suffi cient length to keep the

chains, straps, or cables from contacting the elevat-

ing assembly or platform.

y

y

y

y

Tie-Down/Lifting Lugs

Tie-Down/Lifting Lugs