Daily preventative maintenance checklist, Aily, Reventative – Snorkel TM12-sn7352+ User Manual

Page 15: Aintenance, Hecklist

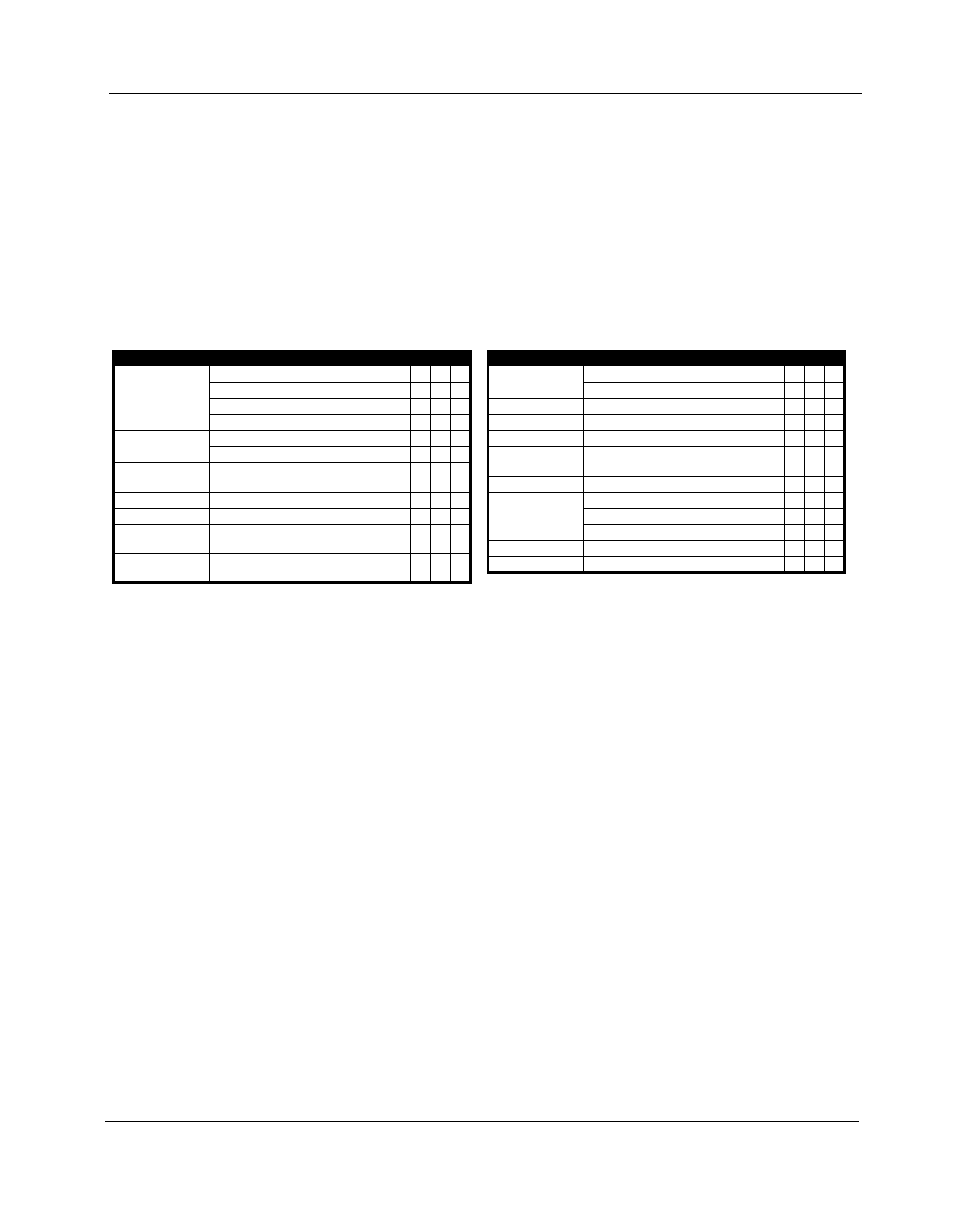

Daily Preventative Maintenance Checklist

107098-002 TM12 - Operator Manual

Page 13

D

AILY

P

REVENTATIVE

M

AINTENANCE

C

HECKLIST

M

AINTENANCE

T

ABLE

K

EY

Y = Yes/Acceptable

N = No/Not Acceptable

R = Repaired/Acceptable

P

REVENTATIVE

M

AINTENANCE

R

EPORT

Date: _______________________________________

Owner: ______________________________________

Model No: ___________________________________

Serial No:____________________________________

Serviced By: _________________________________

COMPONENT

INSPECTION OR SERVICES

Y

N

R

Battery

Check electrolyte level.

Check battery cable condition.

Charge batteries

Check charger condition and operation

Chassis

Check hoses for pinch or rubbing points.

Check welds for cracks.

Control Cable

Check the exterior of the cable for pinching,

binding or wear.

Controller

Check switch operation.

Drive Motors

Check for operation and leaks.

Elevating Assembly

Inspect for external damage, dents, loose rivets

or cracks.

Emergency Hydraulic

System

Operate the emergency down valve and check

for serviceability.

Entire Unit

Perform pre-operation inspection.

Check for and repair collision damage.

Hydraulic Fluid

Check fluid level.

Hydraulic Pump

Check for hose fitting leaks.

Hydraulic System

Check for leaks.

Labels

Check for peeling, missing, or unreadable

labels & replace.

Lift Cylinder

Check for leaks

Platform Deck and

Rails

Check welds for cracks.

Check condition of deck.

Check entry way closure.

Tires

Check for damage.

Wheels

Check for loose components

COMPONENT

INSPECTION OR SERVICES

Y

N

R