Snorkel MB20-sn1000+ User Manual

Page 13

2 - 3

2. Operation & Specifications

2.3 S

AFETY

I

NSPECTION

This Safety Inspection shall be carried out by the owner immediately prior to

transporting this machine.

This Safety Inspection shall also be carried out by the user

prior to use each day.

The procedure is to carry out the following 14 checks in order as follows.

1. Remove the rear chassis covers by means of the two top twist-locks and the two lift-

and-turn catches at the sides. The cover is removed by sliding it backwards and

upwards. Use the central handle provided.

2. Ensure that the mast and jib are fully lowered. Remove the hydraulic oil filler cap and

check that the hydraulic oil level is correct. Oil should be visible on the dip stick. Top up

as necessary using hydraulic oil Viscosity Grade ISO 46.

3. Inspect the chassis area for oil leaks, loose parts, frayed cables and hoses and

structural damage etc. Check that all cable connections to the solenoid valves are

intact.

4. Open the Inspection hatches on both sides of the upper mast cover. Check that the AC

mains cable is disconnected from the battery charger. Check the electrolyte level in

each battery cell. Top up as necessary with distilled water only.

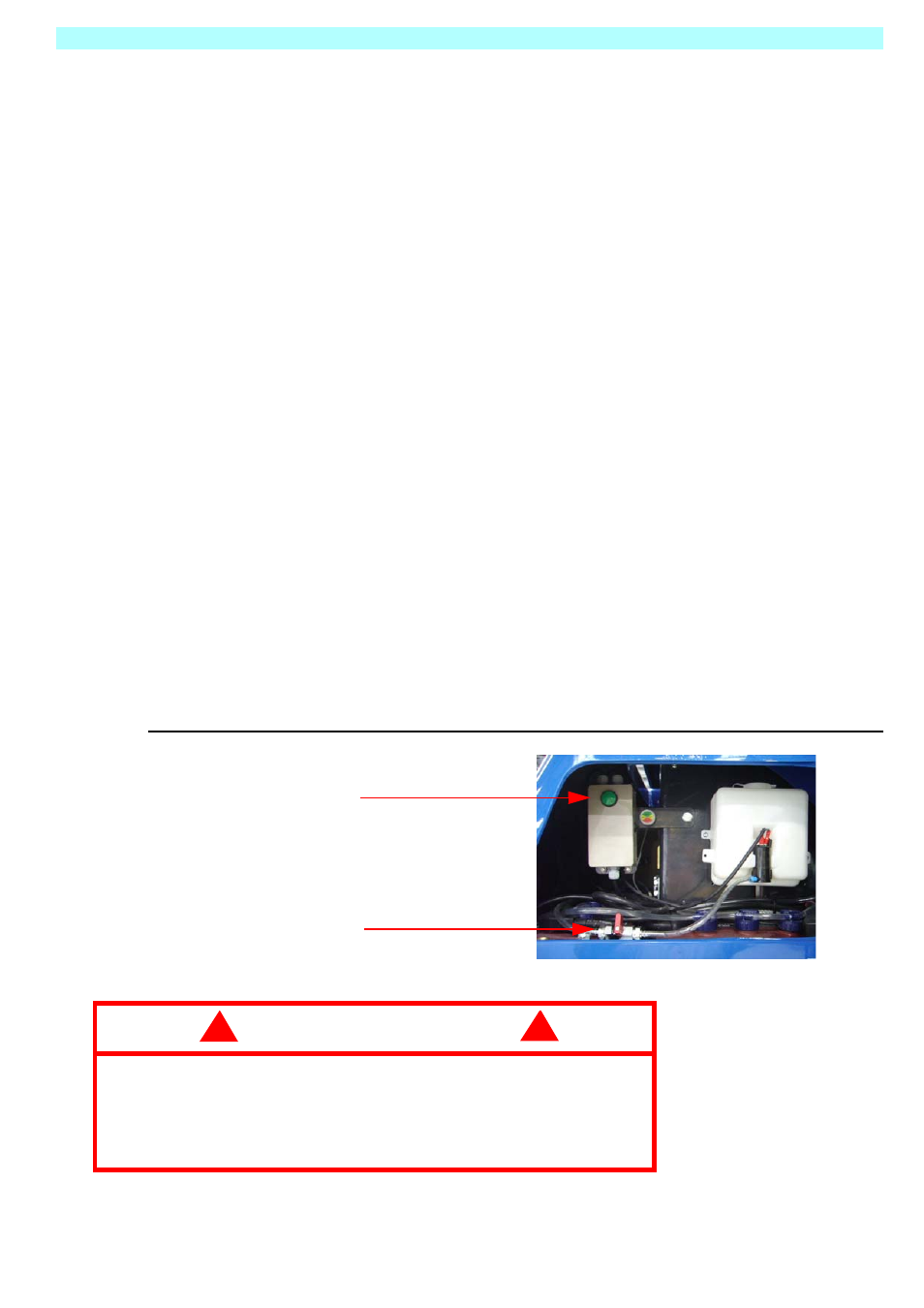

5. Use the automated battery top-up system fill the batteries to the correct electrolyte

level. This is done by opening the shut off valve and pressing the green fill button for

approximately 10 seconds, then re-closing the shut-off valve.

Batteries should be examined for cracks, acid leakage and terminal corrosion. Take

corrective action immediately if either check fails.

Figure 3: Battery Fill Button & Valve

Battery fill Button

Shut off Valve

In CLOSED Position

C A U T I O N

!

!

Vehicles fitted with the automated battery top-up system

with shut

off valve, top up the battery cells with distilled water using the

electrolyte fill button, ensuring that the shut-off valve is open during

the fill and closed after use.

This is the

only time this valve should be opened.