Maintenance, Blocking elevating assembly, Brace installation – Snorkel LX50-sn4022+ User Manual

Page 16: Brace removal

Page 14

Operator Manual

067903-004R1 LX Series Work Platform

Maintenance

M

AINTENANCE

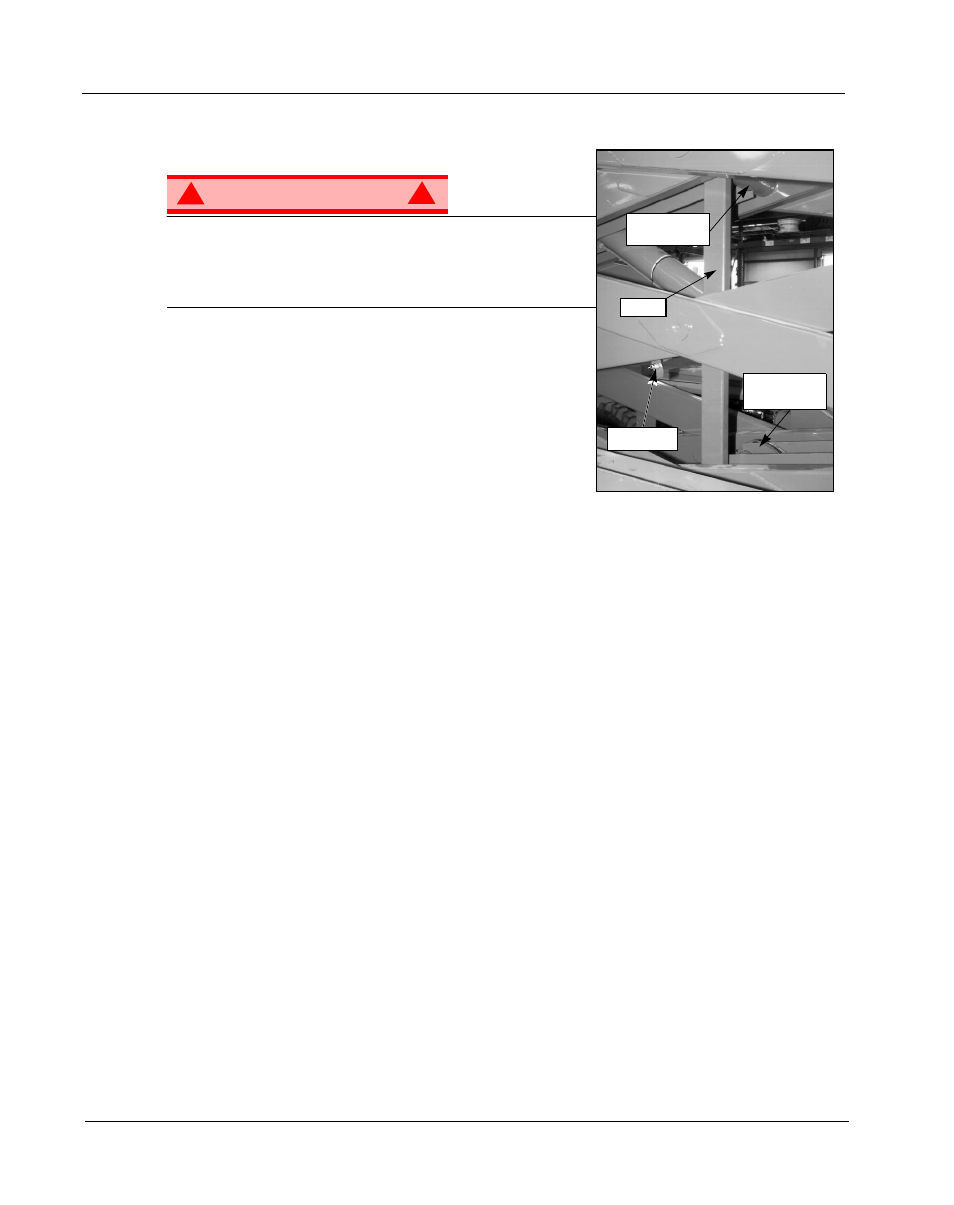

Figure 11: Blocking Elevating Assembly

W A R N I N G

!

!

Never perform service on the work platform in the elevating

assembly area while the platform is elevated without first blocking

the elevating assembly.

DO NOT stand in elevating assembly area while deploying or

storing brace.

B

L O C K I N G

E

L E V A T I N G

A

S S E M B L Y

B

RACE

I

NSTALLATION

1. Park the work platform on firm, level ground.

2. Verify that the platform Emergency Stop button is ON.

3. Turn the Platform/Chassis switch to CHASSIS.

4. Start the engine, using the chassis controls.

5. Push the Throttle button in. The button will stay in and the engine speed will increase. Using the Raise

button, elevate the platform until the scissor brace can be rotated to the vertical position.

6. From the left side of the machine, disengage the locking pin securing the brace. Rotate the scissor

brace counterclockwise until it is vertical and between the two scissor center pivots.

7. Push the Lower button and gradually lower the platform until the brace is supporting the platform.

8. Disengage the throttle by pushing the Throttle button in again. The button will retract and the engine will

come to idle speed.

B

RACE

R

EMOVAL

1. Using the chassis controls, gradually raise the platform until the scissor brace clears the two scissor

center pivots.

2. Rotate the scissor brace clockwise until the locking pin engages.

3. Push the Lower button to completely lower the platform.

4. Make sure the Throttle button is disengaged and Platform/Chassis switch is on PLATFORM.

Brace

Upper Scissor

Center Pivot

Locking Pin

Lower Scissor

Center Pivot