Micropump GL Series Service Instructions User Manual

Page 7

MICROPUMP, INC.

A Unit of IDEX Corporation

PO Box 8975, Vancouver, WA 98668-8975 • Phone: 360/253-2008 • Fax: 360/253-8294

MICROPUMP

LIMITED

A Subsidiary of Micropump, Inc.

Forge Close, Eaton Socon, St.

Neots, Cambridgeshire, PE 19 3TP England, • Phone: (44) (0) 1480-219844 • Fax: (44) (0) 1480-476959

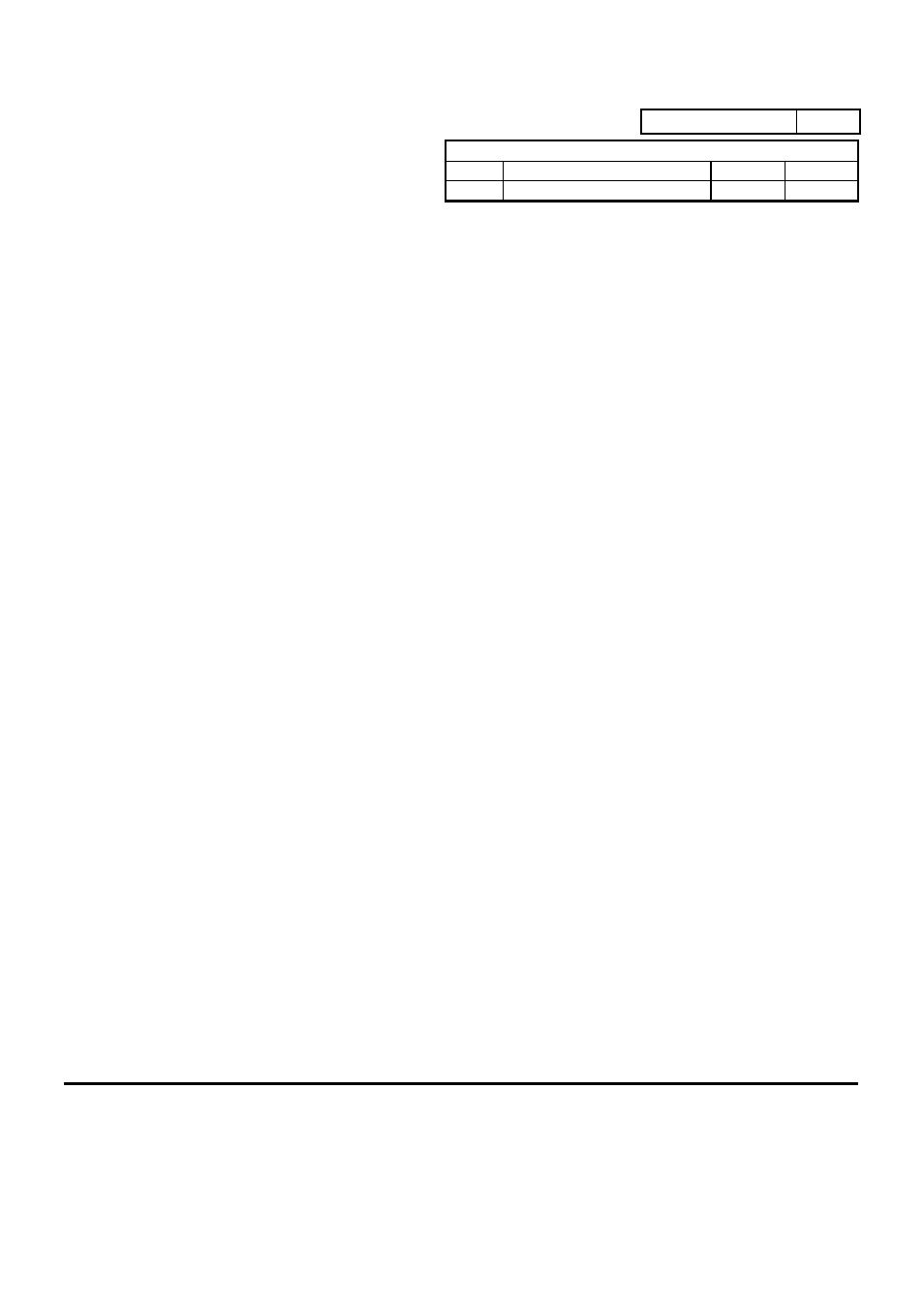

REVISION

LTR.

DESCRIPTION

DATE

BY

C

REVISED PER ECN 4725

11-11-98

LFK

PART NUMBER:

6779

Page 7 of 7

7.13 Complete the Pump Assembly with 8 Screws (J) through Housing (I) into Pump Body (F), and

tighten to 28 to 30 in.-lbs. (3,2 to 3,4 N-m). It is advised to apply a light oil to screw threads and

under screw head before installation.

7.14 Check that all screws are seated. There should be no gaps between mating parts.

8. Assembly of Pump Assembly to Motor.

8.1 Check that Driving Magnet (Q) setting is correct for Pump Assembly. Driving Magnet (Q) should be

attached to the motor shaft using key and set screw. For all motor frames accept 143/145TC the Driving

Magnet (Q) is designed so that when placed on motor shaft it will automatically stop at proper setting.

For 143/145TC frame Driving Magnets (Q) see Assembly Instruction sheet 7492 for proper set height.

8.2 Install Pump Assembly onto motor. Care should be taken to not allow Driving Magnet (Q) to impact

Magnet Cup (O) due to high magnetic attraction.

8.3 Determine proper port location and position Pump Assembly accordingly.

8.4 Install 4 Bolts (P) and tighten to 100 in-lb, (13.4 N-m).

8.5 Test pump to applicable specifications for Pump-Motor combination.

9. Storage.

9.1 Prepare pump for storage by installing plugs in inlet and outlet ports.

Note: Tape can be used in lieu of plugs to seal ports.

9.2 Store pump in any position in a ambient temperature-humidity environment.

Note: If storage temperature is below freezing, remove all liquid from pump before storing.

Contact Micropump Corporation for additional service questions