Micropump GL Series Service Instructions User Manual

Page 3

MICROPUMP, INC.

A Unit of IDEX Corporation

PO Box 8975, Vancouver, WA 98668-8975 • Phone: 360/253-2008 • Fax: 360/253-8294

MICROPUMP

LIMITED

A Subsidiary of Micropump, Inc.

Forge Close, Eaton Socon, St.

Neots, Cambridgeshire, PE 19 3TP England, • Phone: (44) (0) 1480-219844 • Fax: (44) (0) 1480-476959

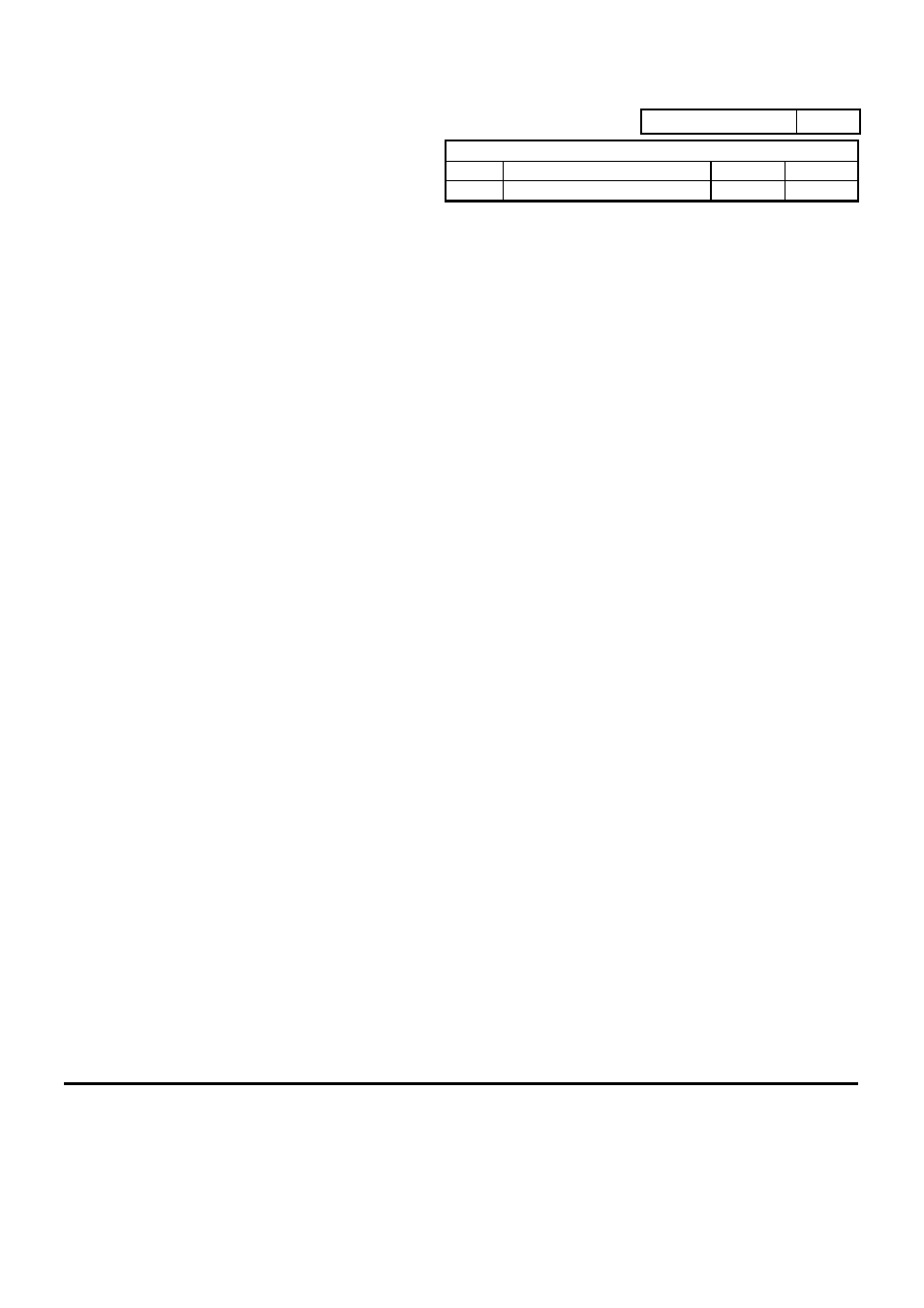

REVISION

LTR.

DESCRIPTION

DATE

BY

C

REVISED PER ECN 4725

11-11-98

LFK

PART NUMBER:

6779

Page 3 of 7

4. Inspection of Pump Assembly components.

4.1 Magnet Cup (O).

4.1.1 Visually check the outside of Magnet Cup (O) for rub marks on the back and sides. Marks on the

back indicate Driving Magnet (Q) is incorrectly adjusted axially. Marks on the side of Magnet

Cup (O) indicate Driving Magnet (Q) is radially misaligned.

4.1.2 Visually check the inside surfaces of Magnet Cup (O) for rub marks. Marks on the bottom

surface indicate that either Driven Magnet (G) or Driving Magnet (Q) is incorrectly adjusted

axially. See Assembly instructions, section 7.12 to correct Driven Magnet (Q) adjustment; see

Assembly Instructions in Motor and Drive Housing Assembly section of Manual for Driving

Magnet (Q) setting. Marks on the inside indicate radial misalignment of Driven Magnet (G); see

Repair Instructions, section 6.2.

4.2 Driven Magnet (G)

4.2.1 Visually check Driven Magnet (G) for wear on the outside shell. See Repair Instructions, section

6.2.

4.2.2 Visually check Driven Magnet (G) for metal particles. See Cleaning Instructions, section 5.2.2.

4.3 Driving Gear (L) and Driven Gear (D)

4.3.1 Visually check the gear teeth on both gears for pits, wear, or damage. REPLACE BOTH GEARS

if either gear is damaged or worn.

4.3.2 Visually check the gear shafts for wear, pits, scoring, or corrosion. Light wear marks on shaft

circumference will normally not impede the operation of pump. REPLACE BOTH GEARS if

either gear shaft is scored, or otherwise damaged.

Note: Always replace all Bushings (K) if either gear shaft is worn or damaged.

4.4 Bearing Plate (B).

4.4.1 Visually check Bearing Plate (B) surface that contacts gears for scoring. See Repair Instructions,

Section 6.4.

4.4.2 Visually check Bearing Plate (B) lube hole (slanted hole) for debris. See Cleaning Instructions,

section 5.2.1.

4.5 Cavity Plate (M).

4.5.1 Visually check the gear cavities in Cavity Plate (M) for scoring in the cavity bores. See Repair

Instructions, section 6.3.