Micropump GL Series Service Instructions User Manual

Page 5

MICROPUMP, INC.

A Unit of IDEX Corporation

PO Box 8975, Vancouver, WA 98668-8975 • Phone: 360/253-2008 • Fax: 360/253-8294

MICROPUMP

LIMITED

A Subsidiary of Micropump, Inc.

Forge Close, Eaton Socon, St.

Neots, Cambridgeshire, PE 19 3TP England, • Phone: (44) (0) 1480-219844 • Fax: (44) (0) 1480-476959

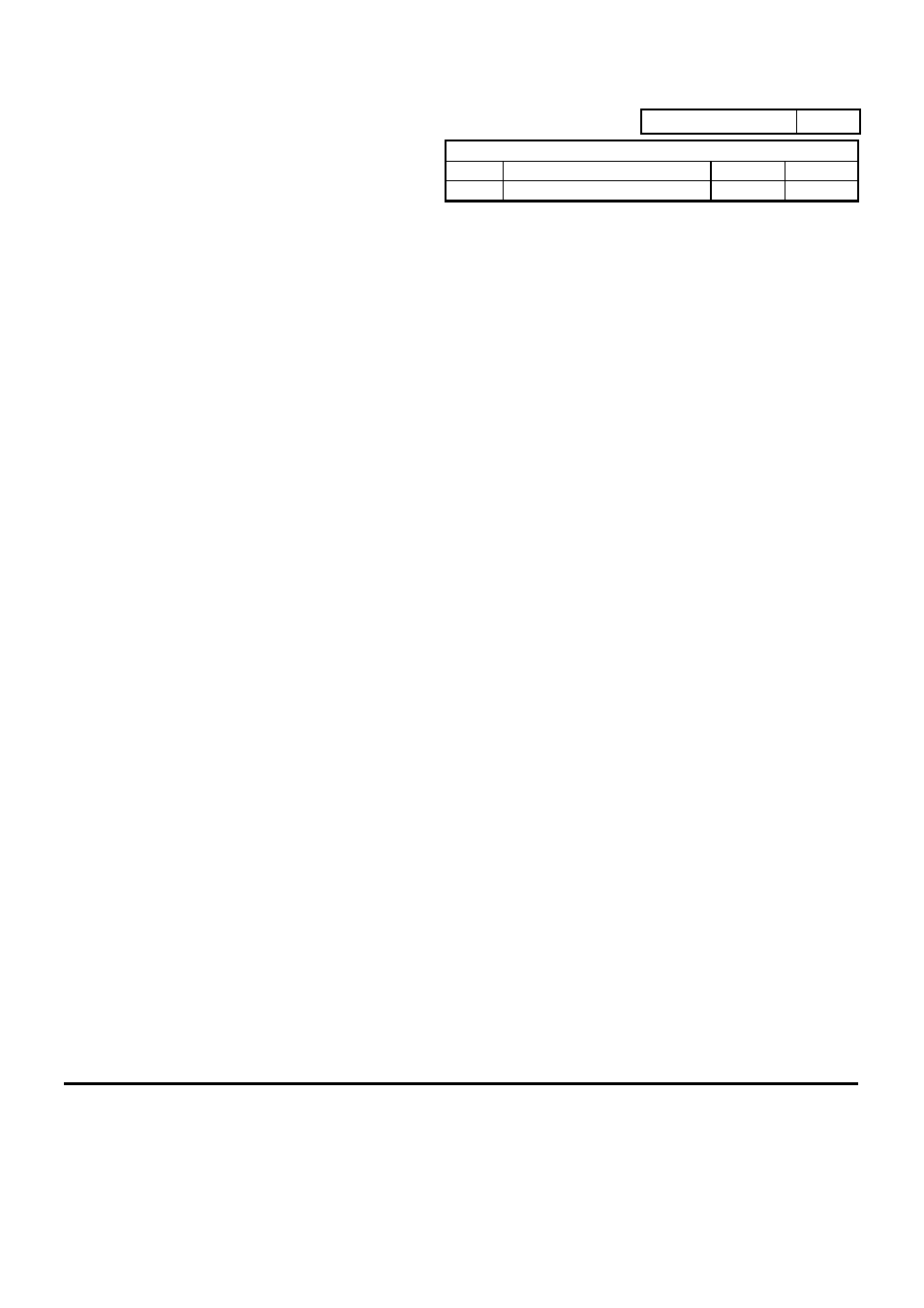

REVISION

LTR.

DESCRIPTION

DATE

BY

C

REVISED PER ECN 4725

11-11-98

LFK

PART NUMBER:

6779

Page 5 of 7

6.4.1 Pump Body (F) and Bearing Plate (B) score marks that are greater than o.010", (.26mm), cannot

be correct by the following procedure. Replace the part.

6.4.2 Minor scoring of Pump Body (F) and Bearing Plate (B) in area of gear contact may be corrected

by lightly sanding with #600 wet-dry sandpaper. Place dry sandpaper on Surface Plate or

equivalent flat surface (i.e. steel plate that has been "sparked out" on a surface grinder). Table

top is not flat enough! Do not use creased sandpaper! Lightly sand in a "figure 8" pattern taking

care to keep part flat against sandpaper. Avoid rocking the part. Normally, the deepest score

marks will be found within a 1/2" (12,7mm) diameter around shaft holes, in the area of contact

with gear wear plate. Typically, scoring outside this area of contact will "clean up" in 4-6 passes

on the sandpaper, and all but the deepest marks within the 1/2" (12,7mm) diameter will "clean up"

in 12-15 passes. If after 20 passes the score marks occupy more than 10% of the total area in

contact with the gear, replace the part. Do not attempt to sand out deep score marks. Clean the

part thoroughly after sanding; see Cleaning Instructions, section 5.2.1.

6.5 Bushing (K) Installation.

6.5.1 Remove all Bushings (K) from Bearing Plate (B) and Pump Body (F) using a Tap and handle.

Thread tap into Bushing (K) approximately 1/2" (12,7mm) and pull Bushing (K) out.

6.5.2 Install 4 Bushings (K) into Bearing Plate (B) 0.010" to 0.020" (0.26mm to 0.51mm) below Bearing

Plate (B) sealing surface, using Bushing Insertion Tool and hand press or non-rotating drill press.

Note: If Pumphead contains Peek or Carbon bushings, one bushing is used for every 2

Rulon (Teflon) Bushings.

6.5.3 Install the first 2 Bushings (K) into Pump Body (F) 0.010 to 0.020" (0.26 to 0.51mm) below

sealing surface of the "gear end" of Pump Body (F). Install the remaining 2 Bushings (K) into

Pump Body (F) from "Magnet end" of Pump Body (F) until Bushing is flush with Pump Body (F)

surface.

6.5.4 Check all Bushings (K) for installation depth. Check all Bushings (K) after installation with a new

gear shaft to insure that clearance between shafts and bushings is at least a sliding fit.

6.5.5 If bushings are tight on shafts, very carefully hand ream Bushings (K) after installation using a

0.251" (6.4mm) diameter reamer. This should be done as straight as possible to obtain

maximum perpendicularity. DO NOT FORCE REAMER INTO BUSHINGS. DO NOT REAM

BUSHINGS UNLESS NECESSARY.

7. Assembly of Pump Assembly (refer to figure 1).

Caution: Do all work on a clean surface free to metal particles.

7.1 Install Driving Gear (L) into center hole in Pump Body (F); the long end of the gear shaft goes into hole.

The shaft should slide and rotate easily in bushings. If not, see Repair instructions, section 6.5.5.

7.2 Install Driven Gear (D) into the other hole with bushings in Pump Body (F). The shaft should slide and

rotate easily in bushings. If not, see Repair Instructions, section 6.5.5. Check that gears rotate easily