Micropump GL Series Service Instructions User Manual

Micropump Pumps

MICROPUMP, INC.

A Unit of IDEX Corporation

PO Box 8975, Vancouver, WA 98668-8975 • Phone: 360/253-2008 • Fax: 360/253-8294

MICROPUMP

LIMITED

A Subsidiary of Micropump, Inc.

Forge Close, Eaton Socon, St.

Neots, Cambridgeshire, PE 19 3TP England, • Phone: (44) (0) 1480-219844 • Fax: (44) (0) 1480-476959

REVISION

LTR.

DESCRIPTION

DATE

BY

C

REVISED PER ECN 4725

11-11-98

LFK

PART NUMBER:

6779

Page 1 of 7

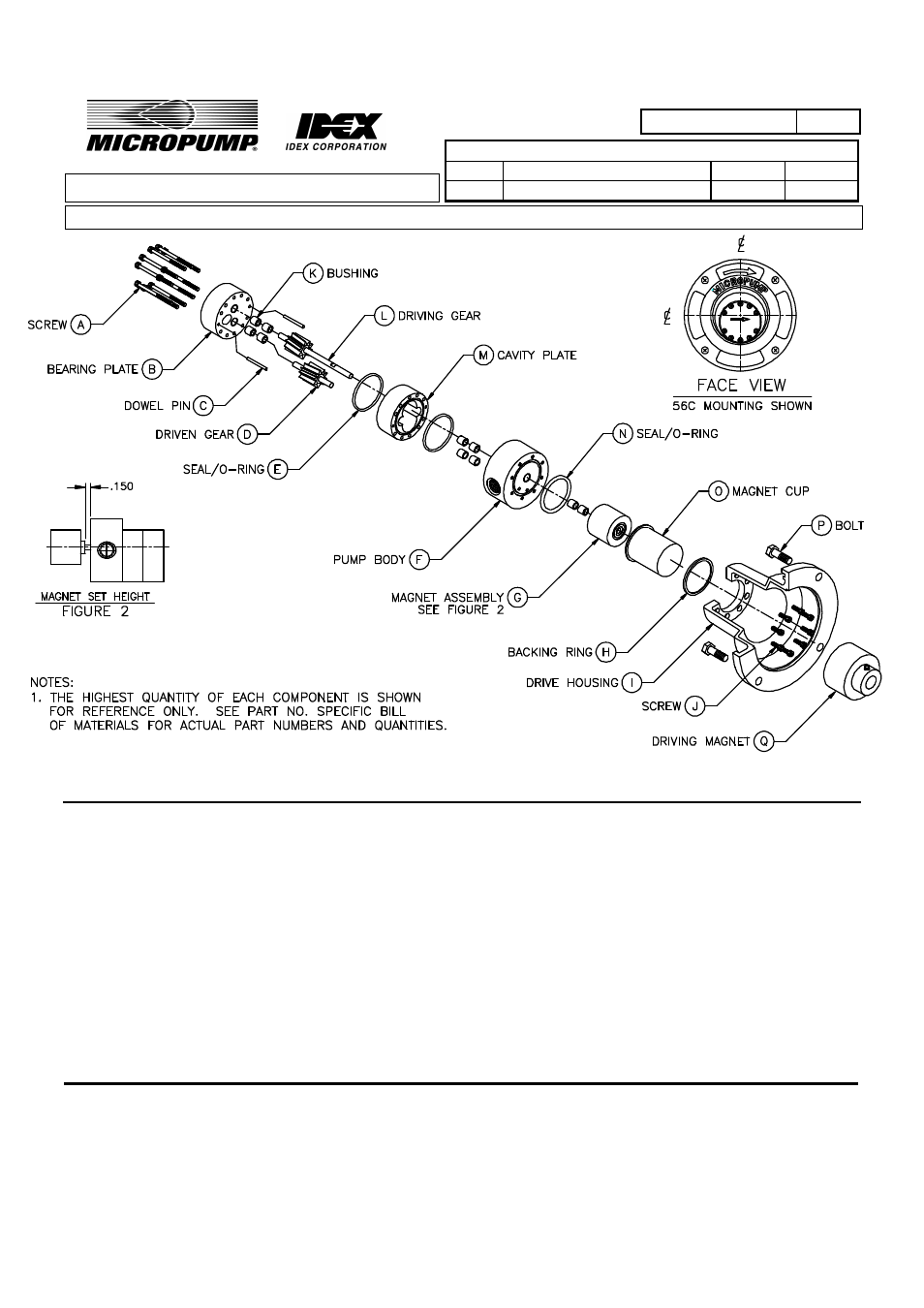

FIGURE 1

1. Description and Operation.

1.1 The Model 5000 pump is a positive displacement gear pump constructed of 316 stainless steel, Teflon,

PEEK and or Carbon.

Special pumps may be constructed from alternate materials. The Pump is magnetically driven and is

therefore leak-proof and contamination free. The pump is self-priming under normal conditions.

1.2 Drive power for the Pump is provided by the Motor and Drive Housing Assembly via the magnetic

coupling. An exploded view is shown in Figure 1. Fluid enters the inlet port and is drawn into the cavity

plate by the negative pressure caused by the gear rotation within the cavity plate. The gear teeth then

move the fluid around the cavity plate walls to the discharge side of the cavity plate. At the mesh point,

fluid is prevented from flowing back to the inlet, and as a result, the fluid is forced out of the cavity

SERVICE INSTRUCTIONS:

MOD: 5000