Micropump GL Series Service Instructions User Manual

Page 4

MICROPUMP, INC.

A Unit of IDEX Corporation

PO Box 8975, Vancouver, WA 98668-8975 • Phone: 360/253-2008 • Fax: 360/253-8294

MICROPUMP

LIMITED

A Subsidiary of Micropump, Inc.

Forge Close, Eaton Socon, St.

Neots, Cambridgeshire, PE 19 3TP England, • Phone: (44) (0) 1480-219844 • Fax: (44) (0) 1480-476959

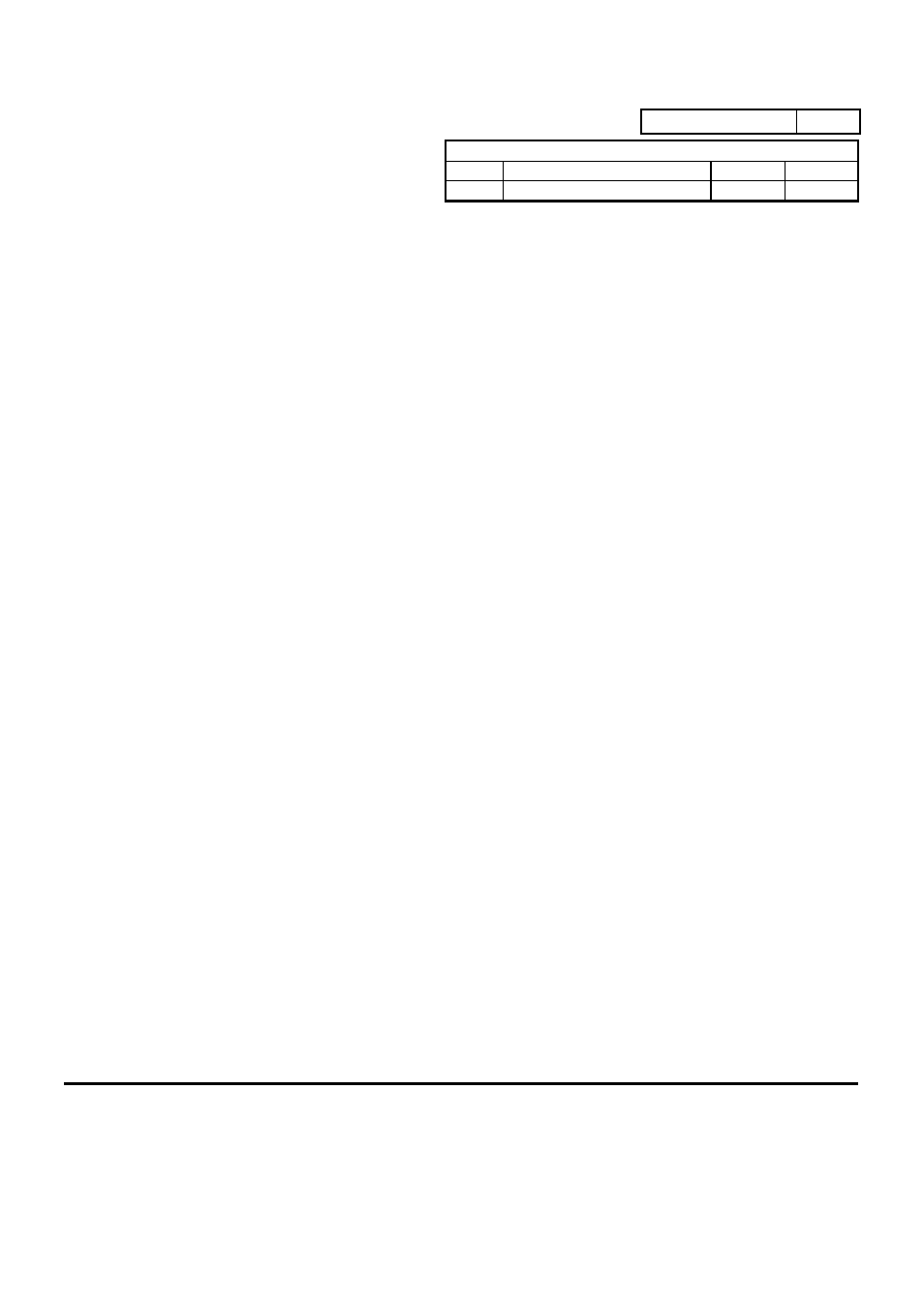

REVISION

LTR.

DESCRIPTION

DATE

BY

C

REVISED PER ECN 4725

11-11-98

LFK

PART NUMBER:

6779

Page 4 of 7

4.5.2 Visually check O-Ring (E) for damage. Replace only if damaged. If necessary to remove, very

carefully use a point X-acto knife at the outside edge of the O-Ring groove in Cavity Plate (M) to

lift O-Rings out of their groove.

4.6 Pump Body (F).

4.6.1 Visually check O-Ring (N) for damage. Replace only if damaged. If necessary to remove, very

carefully use a pointed X-acto knife at the outside edge of the O-Ring groove in Pump Body (F)

to lift O-Ring out of its groove.

4.6.2 Visually Check Pump Body (F) surface that contacts gears for scoring. See Repair Instructions,

section 6.4.

5. Cleaning of Pump Assembly.

5.1 Cleaning Agents and Materials.

5.1.1 Stoddard Solvent, or warm, mild solution of liquid detergent and water. Masking tape.

5.2 Cleaning Procedures.

5.2.1 Clean all metal and plastic parts with the detergent solution, or Stoddard Solvent. Rinse in water

or solvent and allow to dry, or carefully blow dry with clean, dry compressed air.

Caution: Do not use detergent solution or solvent on electrical parts or motor bearings.

5.2.2 Remove all metal particles from Driven Magnet (G) and Driving Magnet (Q) by pressing

adhesive side of masking tape against particles and removing tape.

Note: Loose iron particles and metal fillings will be attracted to the magnet surface and

must be forcibly removed to prevent introducing rust into the system.

6. Repair of Pump Assembly.

Note: Repair of the Pump Assembly is primarily limited to replacing parts.

6.1 Replace any part that exhibits damage such as wear, cracks, breaks, and excessive scoring; see

section 6.4 below regarding scoring of Pump Body (F) and Bearing Plate (B).

6.2 Replace Bushing (K) to correct for side "rub" marks on inside of Magnet Cup (O) and on side of Driven

Magnet (G). See Repair Instructions, section 6.5 below.

Note: Rub marks on Magnet Cup (O) and Driven Magnet (G) may not require replacement of the

part if excessive wear is not present.

6.3 Replace Cavity Plate (M) if gear cavity bores indicate excessive wear or damage.

6.4 Scoring of Pump Body (F) and Bearing Plate (B).